Soybean Oil Processing Cost Framework: A Detailed Cost Model

_11zon.webp)

What is Soybean Oil?

Soybean oil is a major vegetable oil used as food obtained from the seeds of the soybean crop.

Key Applications Across Industries:

It ranks among the world's most significant edible oils, widely utilized in the preparation of foods, processed food items, industrial purposes, and increasingly in biofuels. High in polyunsaturated fats, especially omega-6 fatty acids, soybean oil has applications in non-food industries such as the production of biodiesel, cosmetics, naphthas, and lubricants. The international soybean oil industry involves the entire value chain, including soybean farming and extraction of the oil, refining, packaging, and distribution, for both food-quality and industrial purposes in developed and emerging economies.

What the Expert Says: Market Overview & Growth Drivers

The global soybean oil market size reached 62.29 Million Tons in 2024. According to IMARC Group, the market is projected to reach 72.3 Million Tons by 2033, exhibiting a CAGR of 1.7% during 2025-2033. There are a number of factors driving the international soybean oil industry. First, increasing global food consumption, particularly in Asia-Pacific and Africa, continues to drive demand for edible oils, with soybean oil being an affordable and practical choice. Second, growing application of soybean oil in the manufacture of biodiesel, especially in the U.S. and Brazil, is encouraged by government incentives and carbon emission reduction mandates. Third, heightened awareness of health benefits, including its cholesterol-reducing ability and vitamin E value, is compelling its addition to consumer and processed foods. Along with its further applications in industrial markets, including paints, plastics, and cosmetics, are widening its market base. Increased soybean production and crushing plants, particularly in Argentina, China, and India, are increasing global supply chains and decreasing costs of production. Finally, technological improvements in oil extraction and refining operations are enhancing oil yield and quality, reinforcing the overall market growth.

Case Study on Cost Model of Soybean Oil Processing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale soybean oil processing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed soybean oil processing plant in United Arab Emirates. This plant is designed to produce 20 tons of soybean oil per day.

Processing Process: The processing of soybean oil entails a number of important processes from planting to packaging. Soybeans are first planted in prepared lands, typically planted in spring and ready for harvesting after approximately 100 days, preferably at 14% moisture. The harvested soybeans are then delivered to processing plants by trucks or trains. Upon delivery, they are stocked in silos that are designed to preserve quality and avoid spoilage. During the conditioning stage, soybeans are dried, cleaned, and dehulled in readiness for processing. They are then flaked into a thin fragment to maximize the surface area, which improves the efficiency of oil extraction. The flakes are either mechanically or by solvents such as hexane extracted to remove oil from the meal. The crude oil is thereafter distilled to evaporate the solvents and impurities before the refining process involves degumming, neutralization, bleaching, and deodorization. This enhances the color, flavor, and stability of the oil, guaranteeing quality and nutritional content. Lastly, the oil is filtered and packed in bottles such as PET bottles or transported in bulk to industrial consumers.

_11zon.webp)

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials used in soybean oil processing plant include soybean, n-Hexane and water. For a plant processing 1 ton of soybean oil, 5.75 tons of soybean, 0.01 tons of n-Hexane, and 0.08 cubic meters of water is required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a Processing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

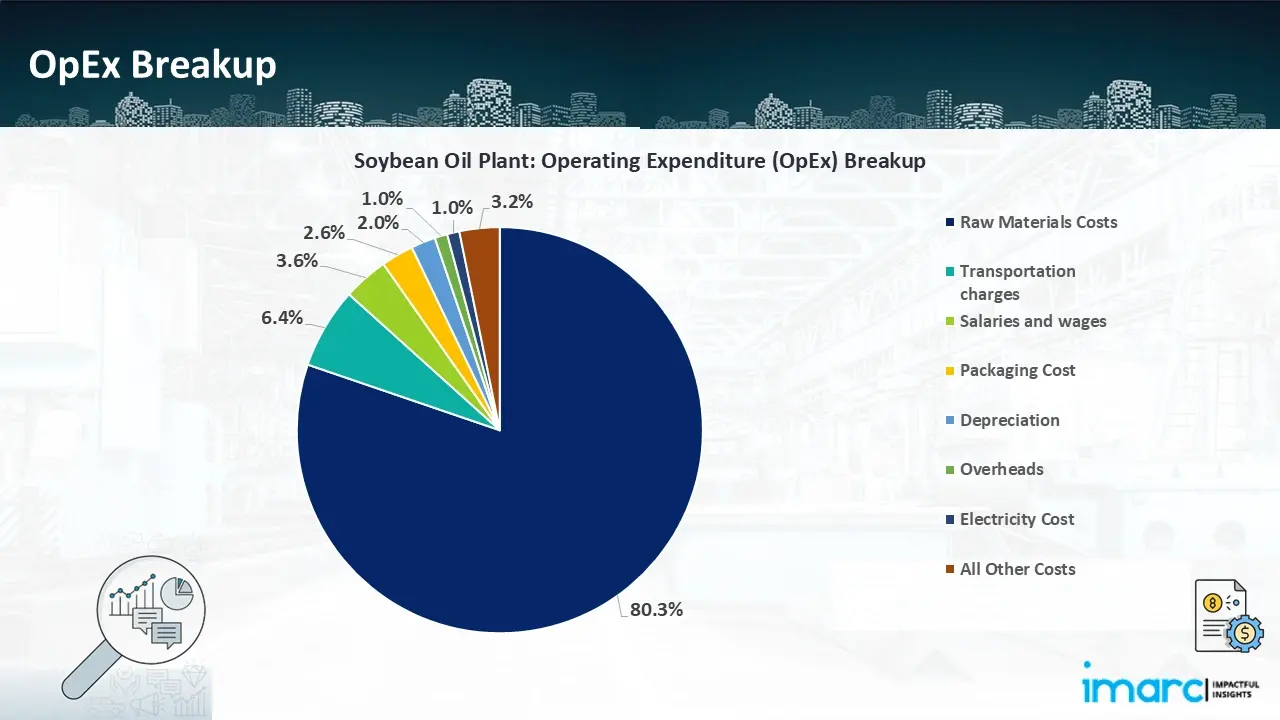

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a Processing plant effectively. Opex in a Processing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a Processing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

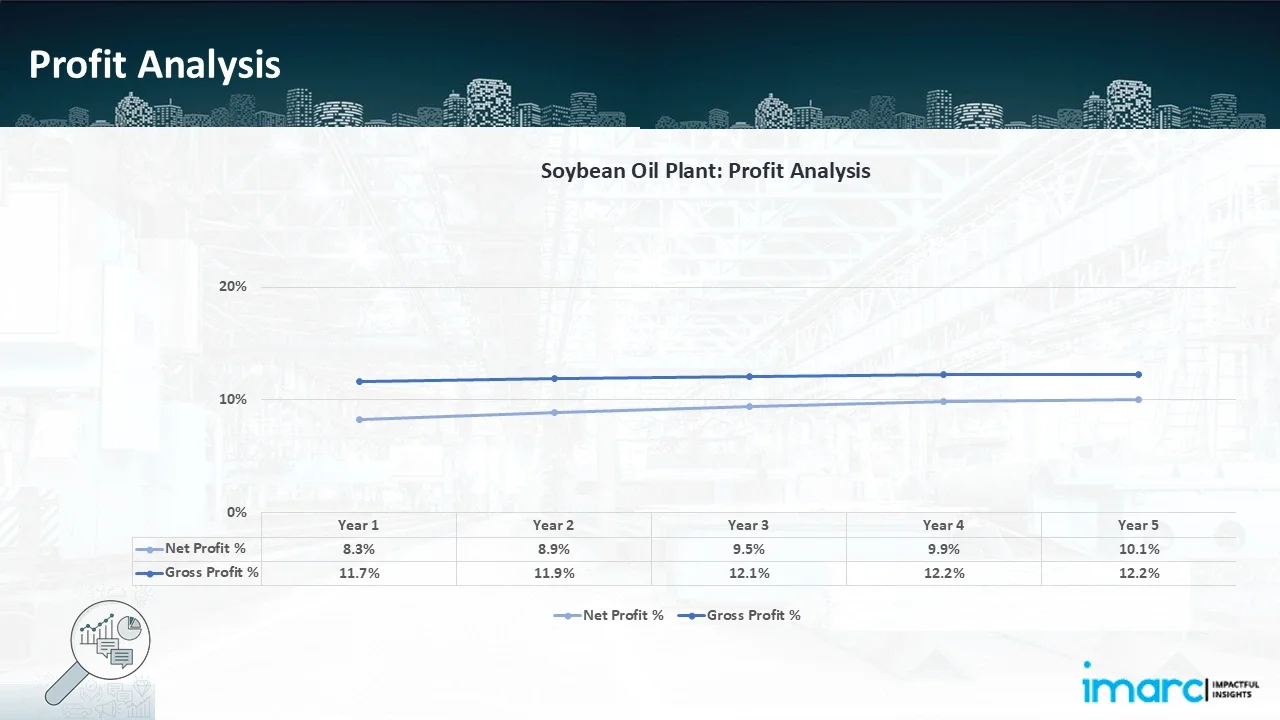

- Profitability Analysis Year on Year Basis: The proposed soybean oil plant, with a capacity of approximately 20 tons of soybean oil per day, achieved an impressive revenue of US$ 21.2 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 11.7% to 12.2% by year 5, and net profit rises from 8.3% to 10.1%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the soybean oil processing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, Processing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 20 tons of soybean oil per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale Processing ventures.

Latest News and Developments:

- In July 2025, Bunge and Viterra completed their historic US$ 34 billion merger, greatly expanding the world's ability to source and manufacture soybean oil. This merger places the merged company in the same size and power as ADM and Cargill.

- In February 2025, Adani Wilmar, the FMCG division of the Adani Group, has formally changed its name to AWL Agri Business Limited after receiving shareholder approval. The decision reflects the company's increased focus on the food and agriculture industries and represents a significant shift for the business.

- In July 2024, the seed innovation business Benson Hill, Inc. announced more developments in its pipeline of innovations to provide end customers in larger soy markets, such as animal feed, soybean oil, and biofuels, with advantageous features. These developments, several of which are currently undergoing field testing, put Benson Hill in a unique position to reshape American soy for fuel and feed by introducing new types that offer exceptional advantages throughout the agribusiness value chain.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the Processing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish Processing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104