Battery Charger Cost Model: Charging Profitability

What is Battery Charger?

A battery charger is a piece of electrical equipment that is used to recharge a rechargeable battery by imposing an electric current upon it. The main purpose of a charger is to transfer alternating current (AC) from the power source into an appropriate direct current (DC) that has the required voltage and current for the particular type of battery.

Key Applications Across Industries:

Battery chargers play a vital role in a broad variety of applications, from consumer devices and electric vehicles (EVs) to industrial equipment and renewable energy systems. There are various charger types, trickle chargers, smart chargers, fast chargers, and wireless chargers, all designed for specific battery types like lithium-ion, lead-acid, nickel-cadmium, or nickel-metal hydride. New battery chargers have seen tremendous changes with the incorporation of intelligent technologies like microcontrollers, sensors, and sophisticated power management systems. These provide accurate voltage control, auto cut-off, and protection from overcharging, overheating, and short circuits, which increase battery lifespan as well as ensure safety. In electric mobility and renewable energy applications, chargers become a more strategic component in load distribution and energy efficiency management. Fast-charging technologies, especially, have transformed the EV and portable device markets by reducing charging time without impacting battery health. With the world's move toward electrification, automation, and integration of renewable sources, the function of battery chargers has evolved beyond an accessory to a catalyst for energy storage and sustainable technology ecosystems.

What the Expert Says: Market Overview & Growth Drivers

The global battery charger market reached a value of USD 26.9 Billion in 2024. According to IMARC Group, the market is projected to reach USD 39.8 Billion by 2033, at a projected CAGR of 4.23% during 2025-2033. The global battery charger market is being propelled by a cross-pollination of technological, industrial, and environmental drivers.

The strongest driver is the surge in electric vehicle (EV) growth globally, driven by government support, emission limits, and customers' demand for clean transport. This has propelled the construction and installation of fast-charging and ultra-fast-charging stations, increasing the demand for high-end chargers that can safely deal with higher power levels. The growth in portable electronic equipment like smartphones, notebooks, and wearable devices also continue to generate constant demand for small and efficient chargers. Concurrently, the growth of the renewable energy industry is pushing the adoption of chargers and battery management systems combined with solar and wind power installations, particularly in off-grid and isolated regions. Advancements in technology like smart charging systems, wireless charging, and integration of Internet of Things (IoT) are further improving charger efficiency, monitoring, and user experience. Battery-powered equipment is being increasingly adopted by industrial sectors for automation, material handling, and logistics, thus giving rise to more growth opportunities. In addition, increasing environmental awareness and regulation-induced mandates to use energy-efficient charging solutions have compelled manufacturers to develop chargers that meet global energy standards (e.g., ENERGY STAR). Asia-Pacific's emerging economies, especially India and China, are experiencing high growth on account of mass production of consumer electronics and EVs. Combined, these elements like technological advancements, trends towards electrification, and policy initiatives are setting the global battery charger market up for long-term growth in the years ahead.

Case Study on Cost Model of Battery Charger Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale battery charger manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed battery charger manufacturing plant in India. This plant is designed to produce 500,000 units of battery charger annually.

Manufacturing Process: The process of manufacturing a battery charger consists of a series of accurate electrical, mechanical, and quality control procedures aimed at creating safe, efficient, and dependable devices. The process starts with design and circuit development when the engineers develop precise schematics specifying voltage, current, and protection parameters according to the battery chemistry (lithium-ion, lead-acid, or nickel-based). After the circuit design, component procurement comes next, including procurement of semiconductors, transformers, capacitors, microcontrollers, and connectors complying with international safety and efficiency standards. The following process is PCB assembly, in which surface-mount and through-hole components are mounted on the board and soldered using pick-and-place and wave soldering machines. The power conversion unit, which comprises mostly AC-DC converters, rectifiers, and voltage regulators, is built to provide stable current output. Microcontrollers and sensors in advanced chargers are added for smart features like automatic cutoff, temperature sensing, and adaptive charge speed. Following electronic assembly, the product goes through mechanical integration, during which the PCB and power modules are encased in thermally resistant plastic or aluminum to provide electrical insulation and heat dissipation. Subsequent quality control and safety testing involve functional tests, insulation resistance, thermal cycling, and overvoltage protection testing. Chargers intended for the global market are subjected to certification compliance testing in certifications like CE, UL, BIS, or RoHS. Lastly, the chargers are marked, packed, and undergo final testing and burn-in to guarantee performance consistency. The end product is a durable, effective, and reliable battery charger for industrial or consumer use.

Get a Tailored Feasibility Report for Your Project Request Sample

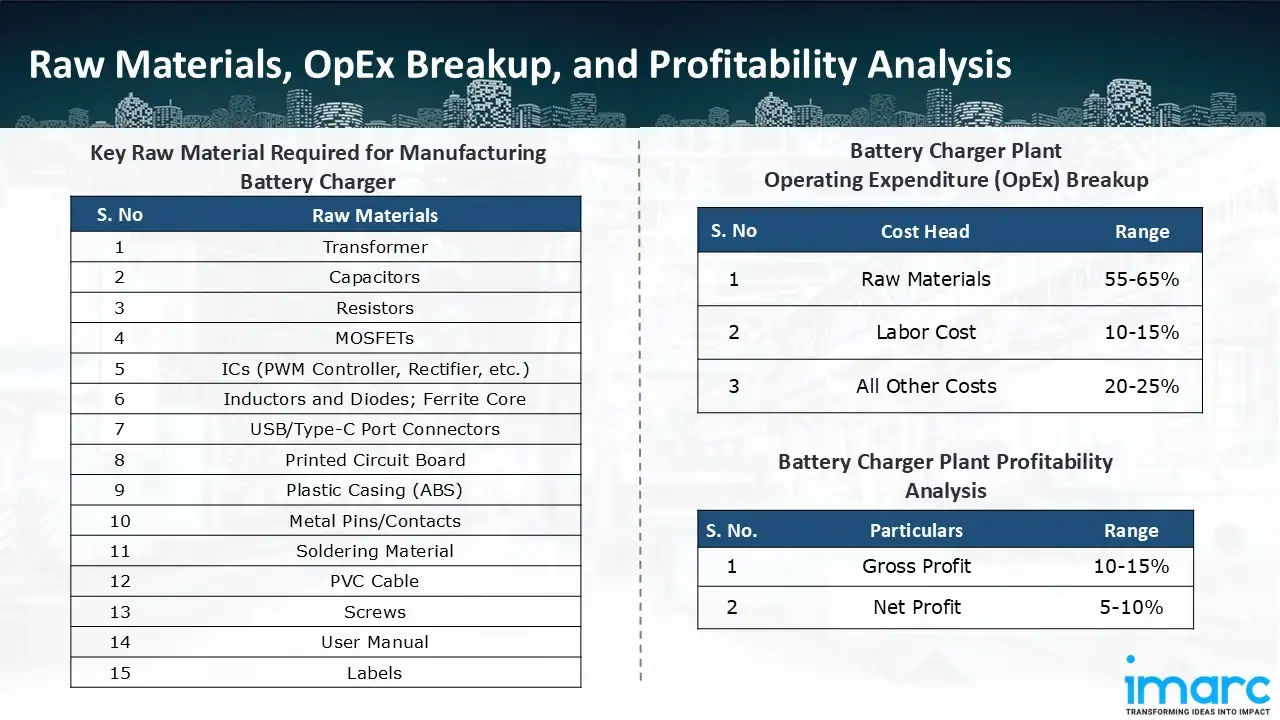

Raw Material Required:

The basic raw materials required for battery charger manufacturing include:

- Transformer

- Capacitors

- Resistors

- MOSFETs

- ICs (PWM Controller, Rectifier, etc.)

- Inductors and Diodes; Ferrite Core

- USB/Type-C Port Connectors

- Printed Circuit Board

- Plastic Casing (ABS)

- Metal Pins/Contacts

- Soldering Material

- PVC Cable

- Screws

- User Manual

- Labels

Machineries Required:

- PCB Fabrication Machine (CNC Drilling and Etching Machines)

- SMT Assembly Line (Pick & Place Machine, Reflow Soldering Machine)

- Through-Hole Soldering Machine (Wave Soldering Machines)

- Transformer Winding Machines (Coil Winding Machines)

- Plastic Injection Molding Machine

- Ultrasonic Welding Machine

- Semi-Automatic Assembly Line

- Jigs/Fixtures

- Testing Equipment (Electronic Load Testers, Aging Testers, Multi-Channel Test Benches, Safety Test Equipment)

- Label Applicators

- Printing Machine

- Automatic Packing Lines

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a battery charger manufacturing plant ranges between 55-65%, labor cost ranges between 10% to 15%, and all other costs ranges between 20-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 10-15%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the battery charger manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 500,000 units of battery chargers annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In January 2025, Olight, a well-known portable lighting company, launched the Ostation X, the first and smartest 3-in-1 battery charger in the world.

- In September 2024, EnerSys announced the commercial launch of its ODYSSEY® battery chargers that can efficiently charge high-quality brands of Absorbed Glass Mat (AGM) batteries, including ODYSSEY® battery models and flooded lead acid and lithium chemistries.

- In January 2024, LG Electronics has established its first electric vehicle charging station assembly facility in the US. The new EV charger manufacturing facility in Fort Worth, Texas, will boost the expansion of EV charging infrastructure across the United States and generate new jobs.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104