Top Factors Driving Growth in the Brazil Ceramic Tiles Market

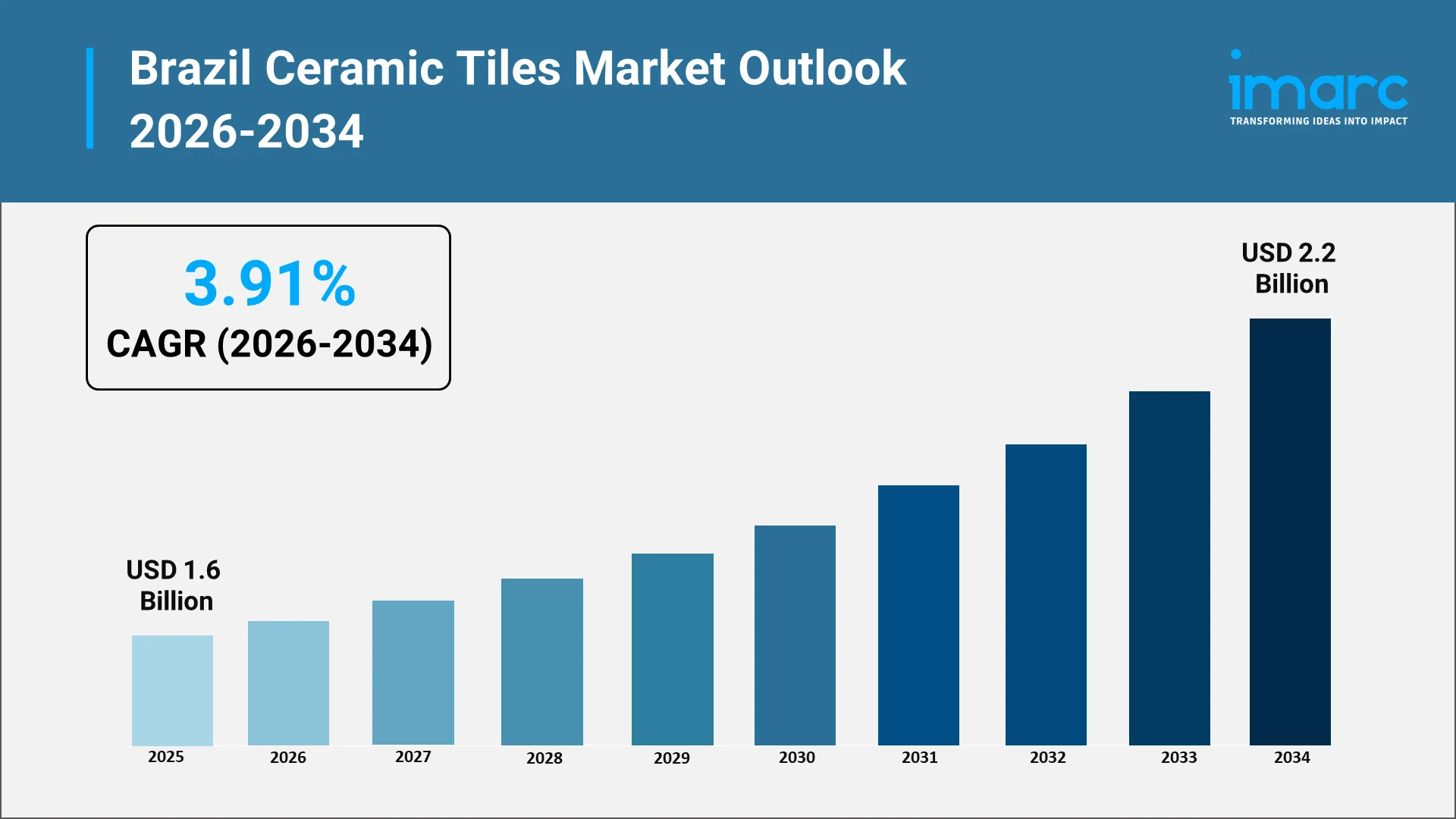

The Brazil ceramic tiles market has witnessed stable growth, reflecting broader trends in the construction and building materials industries of the country. The Brazil ceramic tiles market size was valued at USD 1.6 Billion in 2025. The market is expected to reach USD 2.2 Billion by 2034, exhibiting a CAGR of 3.91% during 2026-2034. Moreover, with Brazil's urban landscape continuing to modernize, the requirement for durable, good-looking, and multi-purpose material has been on a complete rise. Ceramic tiles, being long-lasting, easy to maintain, and suitable for all residential, commercial, and institutional uses, have become the most preferred option. This growth narrative is underpinned by an interplay of factors, including evolving interior design trends, increasing construction growth Brazil, and technological innovations in tile manufacturing. In February 2025, Grupo Almeida announced new ceramic tile collections from showcasing nature-inspired innovations and sustainable manufacturing practices in São Paulo. Moreover, the sector's ability to cater to both domestic needs and international markets has amplified its strategic importance.

Explore in-depth findings for this market, Request Sample

Overview of the Brazil Ceramic Tiles Market:

The Brazil ceramic tiles market covers all kinds of tiles that are used for flooring, walls, and other decorative purposes in residential apartments, corporate offices, retail outlets, and public infrastructures. The market involves different types of tiles, such as glazed, porcelain, and specialty ceramic tiles. Each type has its own characteristics related to durability, aesthetic appeal, and functionality, and due to these reasons, ceramic tiles are becoming an integral part of most modern construction projects. The integration of interior design trends into the product offering is one of the defining features of the market. Indeed, manufacturers are increasingly producing tiles reflecting global styles, while remaining attuned to local tastes. In January 2025, Cejatel announced the pre-launch of its new porcelain tile, showcasing sustainable design, advanced technology, and innovation in Brazil’s ceramic manufacturing sector. Moreover, from minimalist designs to bold, textured finishes, the market reflects a keen sensitivity to consumer aspiration for spaces that are not only functional but also visually compelling. This is in line with the design trend that has strengthened the appeal of ceramic tiles, making them one of the key elements in both luxury and mass-market building projects.

In addition, the Brazil ceramic tile sector is supported by the country's well-developed infrastructure for tile production. Advanced means of production, accompanied by competent labor and accessibility to raw materials, have helped manufacturers maintain the quality and regularity of their products. The infrastructure allows the facilitation of both local demand and ceramic exportation, enabling Brazilian tiles to enter the global market and further improve the country's prestige as a supplier of quality building materials.

Market Size and Construction Industry Trends:

- The growth of the Brazil ceramic tiles market is closely interlinked with broader trends in the construction industry. Urban expansion, residential development, and commercial infrastructure projects have together driven demand for high-quality building materials in Brazil. As cities grow to accommodate ever-expanding populations, so too has the need for robust, versatile, and cost-effective materials raised the profile of ceramic tiles.

- Efficiency, durability, and flexibility in design are increasingly the concerns in all modern construction projects. Ceramic tiles cover a wide range of requirements for wear and tear resistance, water, and environmental conditions, besides offering an incredible diversity in design and finish. New innovations in tile sizes, textures, and colors have made it possible for architects and interior designers to create singular experiences in spaces. In January 2025, Grupo Formigres, a renowned Brazilian floor and wall tile specialist, announced it would launch new products and innovative formats to enhance design sophistication and market appeal. Moreover, these tendencies point to the ongoing paradigmatic shift in construction where functional demands are matched by aesthetic ambitions, making ceramic tiles one of the important choices for urban and residential projects.

- Increasing awareness of the importance of sustainable and resilient construction practices has, naturally enough, filtered into material selection. In this regard, ceramic tiles excel, as they are made from natural ingredients, readily recyclable, and require very low maintenance. These, indeed, are strong aspects relating to their long-term value creation for builders and developers, which in turn further reinforces growth in the construction growth Brazil segment, stirring demand for high-quality building materials Brazil.

Key Factors that Propel Demand and Production:

- Several factors have congregated to enhance both demand and production in the Brazil ceramic tile market. Urbanization, with its ever-expanding cities and mushrooming infrastructure, continues to be one of the major drivers. The need for construction materials that can provide strength yet be aesthetically pleasing drives the demand for ceramic tiles to higher levels, especially in residential complexes, offices, and retail outlets.

- Other critical factors include economic development and increase in disposable incomes. Consumers are increasingly moving towards upgrading their homes and commercial places with high-end and decorative tiles that improve the aesthetics of any interior space. This trend has attracted more players into offering a wide range of innovative designs to accommodate these emerging consumer preferences, mirroring interior design trends as drivers for product development.

- In this context, technological advancements in tile manufacturing have further reinforced the growth of the market. Advanced production methods allow for precision engineering, consistency in quality, and the ability to create intricate patterns, textures, and finishes, which were difficult to achieve earlier. In March 2025, SACMI Do Brasil unveiled its Easy Factory system, introducing hyper-productivity ceramic manufacturing technology that enhances sustainability, digital process control, and automation across Brazil’s ceramic tile industry. Furthermore, automated processes, digital printing, and advanced glazing techniques extend design possibilities, thus enabling manufacturers to fulfill the growing expectations of architects, designers, and end-users.

- Besides, the export potential of Brazilian ceramic tiles greatly enhances further market expansion. High-quality products from Brazil enjoy recognition in international markets, driven by aesthetic versatility, durability, and design sophistication. The possibility of penetrating overseas markets reinforces production volumes and encourages manufacturers to maintain rigorous standards in quality control and product innovation. This global reach underscores the strategic importance of ceramic exports in sustaining the market's growth trajectory.

Role of Design Innovation and Export Potential:

- Design innovation is playing a key role in shaping the Brazil ceramic tiles market. Consumers today are looking more for tiles as a design statement rather than just serving functional purposes. The manufacturers are traditionally adopting these creative ways to expand the aesthetic scope of ceramic tiles, from textured surfaces and geometric patterns to color gradations and even custom prints. This emphasis on design innovation aligns with evolving interior design trends that enable the sector to capture both mass-market and premium segments.

- Customizable tiles and modular designs give architects and interior designers unprecedented flexibility in creating cohesive spaces. As design preferences become more sophisticated, so too does the demand for unique and personalized tile solutions, forcing manufacturers to invest in research and development in order to stay ahead of emerging trends. These successive developments result in increasing variety in product offerings and, along with it, a generally improved aesthetic for ceramic tiles, further cementing them as staples of modern building.

- Besides domestic consumption, exports also form a very important growth avenue. Brazilian tiles enjoy an increasing reputation for quality, craftsmanship, and design sophistication that makes them competitive in international markets. Export-oriented production encourages manufacturers to adopt advanced technologies, implement stringent quality standards, and develop designs that resonate with global consumer preferences. Consequently, the interplay between design innovation and export potential creates a virtuous cycle propelling growth, enhancing brand recognition, and fostering international trade opportunities.

Sustainable Manufacturing and Energy Efficiency:

- Sustainability has emerged as a central consideration in the Brazil ceramic tiles market, with influence on both production methods and product offerings. In this way, manufacturers are increasingly adopting eco-friendly practices that minimize environmental impact while improving operational efficiency. The use of recycled raw materials, energy-efficient kilns, and water conservation measures is part of a broad commitment to sustainable tile manufacturing practices.

- Energy efficiency is integral to this transformation. Advanced production technologies reduce fuel consumption, decrease emissions, and optimize resource consumption. Such practices not only ensure environmental stewardship but also create cost savings for manufacturers, which can be reinvested in innovation and product development. Sustainability considerations are changing consumer preferences as well, with buyers increasingly appreciating products that balance functionality with environmental responsibility.

- Green certifications and environmental standards add to the competitive advantages, as builders and designers also seek materials that correspond to the objectives of sustainable construction. In this context, ceramic tiles make for a material that provides an excellent balance of durability and aesthetic appeal while respecting the environment-a reinforcement of its relevance in residential and commercial projects. The emphasis on sustainability complements initiatives on construction growth Brazil by supporting resilient, eco-conscious urban development.

Competitive Landscape and Future Growth Opportunities:

- The competition in the Brazil ceramic tiles market is very high, consisting of both established and emerging producers intending to take full benefit of growing demand. Competition factors include quality, innovation in design, technological capability, and meeting the changing needs of consumers. In addition, manufacturing companies invest in research and development to differentiate products against changing trends in interior design, thereby maintaining relevance in the local and international markets.

- Other emerging opportunities include diversification into specialty tiles, regional market coverage in unpenetrated areas, and export-oriented production. Further growth may be realized in the development and integration of smart manufacturing, the use of digital design tools, and sustainable production. Furthermore, cooperation among designers, architects, and manufacturers will encourage innovative solutions that improve the functionality and aesthetic appearance of the ceramic tiles.

- The strategic integration of manufacturing capabilities with design innovation and sustainability imperatives positions the Brazil ceramic tiles market for long-term expansion. To gain a competitive advantage, manufacturers should be proactive in embracing technological advancements, anticipating changes in consumer preferences, and emphasizing environmental responsibility. By capitalizing on both domestic demand and international export potential, the market is positioned to establish itself as a key component of the greater building materials Brazil ecosystem.

Conclusion:

The Brazil ceramic tiles market is poised for long-term expansion, supported by a balance of innovation, sustainability, and export competitiveness. As construction growth in Brazil continues to accelerate, ceramic tiles have emerged as a preferred material for both functionality and design appeal. Manufacturers are increasingly blending advanced technology with creative design concepts to meet evolving interior design trends and diverse consumer preferences. Sustainability is now a defining factor, with producers adopting energy-efficient processes, recyclable materials, and eco-friendly manufacturing practices that align with global green building goals. At the same time, Brazil’s strong production base and growing ceramic exports reinforce its position in the international building materials landscape. With design innovation driving domestic consumption and international recognition, the market is set to maintain its momentum. Companies that focus on quality, technological development, and environmental responsibility will be well-placed to lead future growth in the Brazil ceramic tiles market.

IMARC Group: Choose Us Because We Offer Unmatched Expertise and Core Services

- Data-Driven Market Research: In-depth market research reports strengthen understanding of Brazil’s ceramic tile demand by analyzing construction activity, residential renovation patterns, interior design preferences, and advancements in tile manufacturing, including digital printing and sustainable production technologies.

- Predicting Strategic Growth: Forecasting enables a clear view of future expansion shaped by urban development, eco-friendly building materials, aesthetic customization, and government-backed housing programs, helping predict strategic growth across Brazil’s key regional construction markets.

- Competitive Benchmarking: Competitive analysis supports evaluation of market forces within Brazil’s ceramic tile industry by examining product innovation, manufacturing upgrades, supply chain efficiency, and emerging design trends that enhance durability, sustainability, and visual appeal.

- Policy and Infrastructure Advisory: Guidance on environmental standards, construction regulations, energy-efficient building norms, and infrastructure development initiatives helps stakeholders stay aligned with evolving policies influencing ceramic tile production and market penetration.

- Custom Reports & Consulting: Tailored insights help organizations launch new tile collections, expand distribution networks, adopt innovative manufacturing technologies, and invest in sustainable building materials to capitalize on Brazil’s fast-growing construction and interior design landscape.

At IMARC Group, we aim to empower industry decision-makers with the intelligence required to leverage Brazil’s rising ceramic tile demand. Together, we support a more sustainable, innovative, and design-driven future for the building materials sector.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104

.webp)