Corn Starch-Based Tableware Manufacturing Cost Model: From Sourcing to Sustainable Profitability

_11zon.webp)

Corn starch tableware is a new and ecofriendly solution to traditional plastic disposable items, which aims at solving the increasing environmental issues linked to plastic waste. Comprising mostly of corn starch, a plant-based and renewable resource, the products range from plates, bowls, cups, cutlery, and food containers, all of which are completely biodegradable and compostable. In contrast to conventional plastics, which require centuries to biodegrade, corn starch tableware naturally disintegrates in months under optimal composting conditions, thereby sharply lessening landfill waste and sea pollution. During production, the process also results in less greenhouse gas emissions than petroleum-based plastics, following international carbon reduction targets. As regulatory prohibitions on single-use plastics grow, along with a move toward the circular economy concept, corn starch tableware has gained popularity with eco-responsible customers, foodservice outlets, and corporate clients. Because it is non-toxic, light in weight, and functional, it stands out as a good choice for both regular use and mass gatherings, making it a major player in sustainable packaging solutions.

The global market for corn starch tableware is growing at a fast pace due to a range of regulatory, green, and consumer-led drivers. Among the major drivers is the number of government bans and limitations on single-use plastics, which is rising. Governments in countries in Europe, North America, and Asia-Pacific have also enforced strict policies to eliminate plastic disposables, pushing companies and consumers to switch to biodegradable ones such as corn starch tableware. In addition to regulatory forces, increased environmental consciousness from consumers is driving demand. Increasingly, a segment of environmentally conscious consumers favors sustainably produced products at a premium, as they understand the long-term environmental payoff. The food service market, restaurants, cafes, and catering operations are heavy users, prompted by compliance needs as well as customer demands for more environmentally friendly packaging options. Furthermore, advances in biopolymer manufacturing have also played their part, with manufacturers evolving more robust, heat-tolerant, and affordable corn starch-based products that can match conventional plastics in terms of performance. The growth of e-commerce has also spurred accessibility further, enabling green tableware to move into wider markets via online shopping platforms. Urbanization and the rapid lifestyle in emerging economies are driving demand for convenient but sustainable disposable tableware, especially for takeout and delivery food. Together, these forces are driving the corn starch tableware market toward major expansion as a cornerstone of global trend toward sustainable consumption.

Case Study on Cost Model of Corn Starch Based Tableware Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale corn starch based tableware manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed corn starch-based tableware manufacturing plant in Arizona, United States. This plant is designed to produce 221 kg of corn starch-based tableware per day.

Manufacturing Process: The production of corn starch-based tableware starts with the isolation of starch from corn, which is blended with water, biodegradable polymers (PLA or PHA), and natural fillers to create strength and heat resistance. The blend is then heated and kneaded into a soft bioplastic resin, which is subsequently injection-molded or thermoformed into plates, bowls, cutlery, or other shapes of tableware. Following shaping, the products are dried and chilled to solidify their structure. Some producers spray a slim, food-grade coating on to enhance water resistance. The last stage is quality control for durability and biodegradability before the products are packaged. Because no harmful chemicals are utilized, the production is eco-friendly with little waste—any scraps made in the process can usually be recycled again into the cycle of manufacturing. The whole process uses less energy than traditional plastic production and is based on renewable resources, so corn starch tableware is a green option. The final products break down in months under composting conditions and leave no toxic residues.

_11zon.webp)

Mass Balance and Raw Material Required: The primary raw materials used in the corn starch-based tableware manufacturing plant include corn starch, calcium chloride and glycerol. For a plant producing 1 kg of corn starch-based tableware, 0.803 kg of corn starch, 0.165 kg of calcium chloride, and 0.062 kg of glycerol.

Types of Machinery:

- 200 L High Speed Mixe

- Spiral Load Feeder

- GS-50B Twin Screw Extruder

- Twin Screw Metering Feeder

- Main Motor:Siemens Motor

- Gear Box

- Screw and Barrel, Heating Section

- Soft Water Cooling System

- Vacuum System

- Hydraulic Pressure Automatic Screen Ex-Changer

- Strand Head, Die Head

- Electrical Control System with PLC Touch Screen

- Conveyor Belt Pelletizer Syetem

- Others Equipments (i.e. Screws, Mold Clamping with Bolts, Tool Box, etc.)

- Injection Molding Machine Servo,KBD2680

- Auto Loader 800G

- Hopper Dryer 100KG

- Chiller 15AC

- Mixer 100KG

- Knife Mold 24 Cavities

- Fork Mold 24 Cavities

- Spoon Mold 24 Cavities

- Plate 2 Cavities

- SG Three Phase Transformer

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

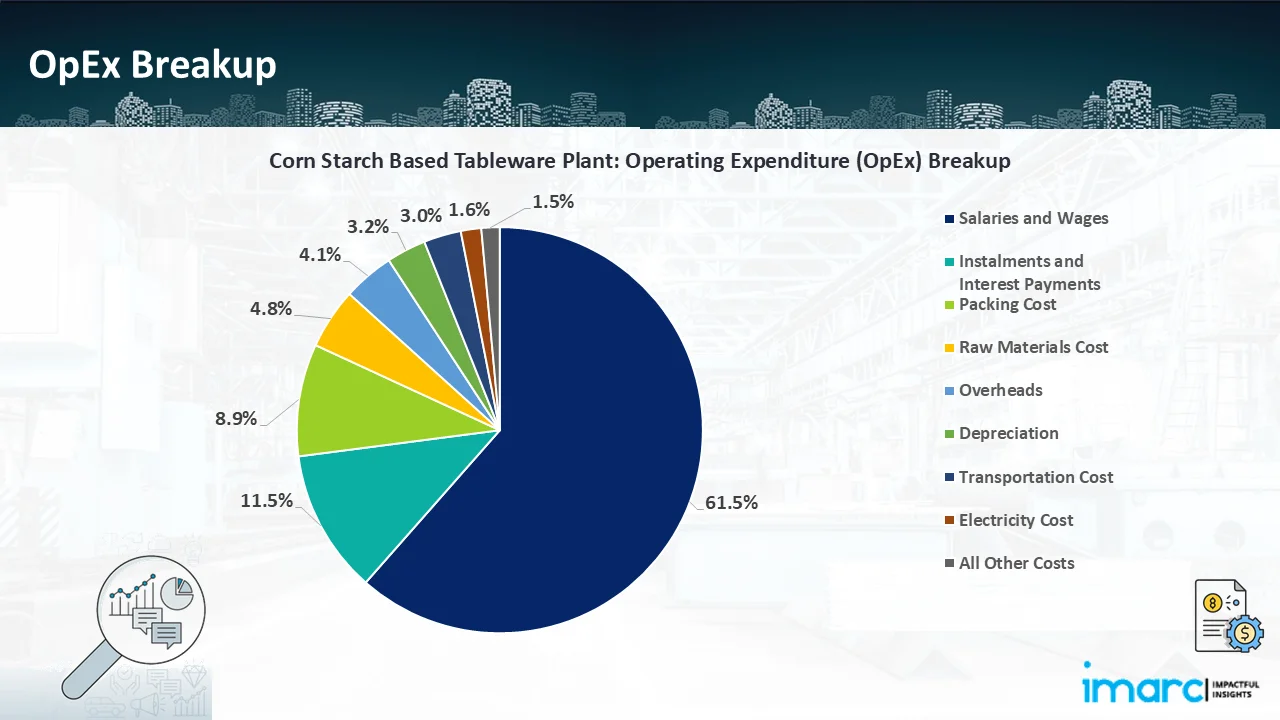

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

- Profitability Analysis Year on Year Basis: The proposed corn starch-based tableware plant, with a capacity of 221 kg of corn starch-based tableware per day, achieved an impressive revenue of US$ 0.635 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross earnings improve from a negative of 16.3% to a positive of 26.6%, and net earnings improve from a negative of 21.5% to a positive of 18.2%, highlighting strong financial viability and profitability.

_11zon.webp)

Conclusion & IMARC's Impact:

Our financial model for the corn starch-based tableware manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 221 kg corn starch-based tableware per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In January 2025, Corn Next Introduces CornNext-17: An Innovative...CornNext unveiled "CornNext-17" in early 2025, a biodegradable substance derived from corn starch that is intended to take the place of conventional plastics in applications including cutlery and tableware.

- In May 2024, Krungthai Bank PCL has provided unprecedented financial support to NatureWorks, a leading producer of polylactic acid (PLA) biopolymers derived from renewable resources, in order to optimise the capital structure for the new fully integrated Ingeo PLA production plant in Thailand.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104