CCTV Camera Cost Model: Deep Dive into Surveillance Cost

Closed-Circuit Television (CCTV) cameras are electronic monitoring systems that are used to watch, record, and send video images for security and observational reasons. Unlike television broadcasting, CCTV signals are sent to selected monitors or recording devices, and hence they are the backbone of contemporary security infrastructure. CCTV systems are extensively employed in commercial, domestic, industrial, and governmental environments to discourage crime, observe open areas, and provide operational security. There are different CCTV camera types like analog, IP (Internet Protocol), dome, bullet, PTZ (pan-tilt-zoom), and thermal cameras to meet diverse surveillance requirements. The latest developments have introduced AI-based analytics, face recognition, motion detection, and cloud storage, turning CCTV systems into intelligent surveillance solutions. Production of CCTV cameras requires sophisticated electronics, optical engineering, and data processing technologies with a focus on high-definition imaging, low-light capabilities, and connectivity. With urbanization, digitalization, and security consciousness on the rise, CCTV cameras are now a necessity to protect assets, govern traffic, and provide public security. The industry is advancing further towards smart surveillance networks based on IoT and AI for real-time decision-making and predictive security management. The global CCTV camera market reached a value of USD 44.15 Billion in 2024. According to IMARC Group, the market is projected to reach USD 128.47 Billion by 2033, at a projected CAGR of 11.6% during 2025-2033. The global CCTV camera market is powered by growing security threats, urbanization, and the increasing use of smart city projects. Private companies and government bodies are putting significant money into surveillance systems for improving crime prevention and traffic management. Advances in technologies like AI-driven video analytics, cloud computing, and edge processing have further transformed the industry with remote monitoring and real-time response capabilities. The growth of retail and e-commerce sectors has also increased demand for loss prevention and in-store monitoring systems. Further, convergence of CCTV systems with IoT networks enables smart infrastructure management, driving adoption in industrial and residential applications. Apart from this, declining costs of cameras, higher internet penetration, and rising consumer awareness of home security systems have driven market growth. Asian-Pacific, Middle Eastern, and African emerging economies are seeing an upsurge in public infrastructure development and security program modernization, which is providing significant opportunities for international manufacturers. Watching the environment, border protection, and intelligent transport systems are also expanding the scope of CCTV camera applications across the globe.

Trending Insights on CCTV Camera: Latest News and Developments

- In June 2025, Honeywell announced the introduction of its first locally developed and manufactured camera portfolio, the 50 Series line of CCTV systems. The cameras are conceptualised, created, and produced in India in accordance with the government's Atmanirbhar Bharat goal. According to the government's "Make in India" policy, the cameras are Class 1 certified, which is the highest category level.

- In April 2025, following the implementation of government regulations, which now require STQC certification for all IP CCTV cameras sold in India, Sparsh, an Indian manufacturer of CCTV cameras and electronic security solutions, announced its continued leadership in the Indian market by being the first Indian firm to achieve STQC (Standardisation Testing and Quality Certification) for the most extensive range of its CCTV products.

- In April 2025, India enacted new compliance laws for CCTV production mandating stringent adherence to cybersecurity, safety, and quality standards. All CCTV cameras must comply with Bureau of Indian Standards (BIS) safety regulations and pass Essential Requirements (ER) testing by Standardisation Testing and Quality Certification (STQC), according to regulations set by the Ministry of Electronics and Information Technology (MeitY).

Case Study on Cost Model of CCTV Camera Manufacturing Plant:

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale CCTV camera manufacturing plant. We developed a comprehensive financial model for the setup and operation of a proposed CCTV camera manufacturing plant in India. This plant is designed to manufacture 120,000 units of CCTV camera annually.

Manufacturing Process: Manufacturing a CCTV camera is a blend of high-tech electronic engineering, precision lenses, and quality control to ensure endurable surveillance equipment. The process starts with design and component procurement, where engineers create detailed blueprints for the camera's hardware and source high-quality components like image sensors, lenses, printed circuit boards (PCBs), and case components. The most important component is the image sensor, normally a CMOS or CCD chip, which captures visual information. During the assembly stage, the sensor is placed on the PCB that includes the processor, memory, and other electronic elements necessary for image processing and data transmission. The lens assembly is subsequently fitted, calibrated, and adjusted to be in focus and at correct field of view. For digital cameras or IP, network modules and firmware are built in to facilitate data transfer and intelligent capabilities like motion detection or AI-driven analysis.

After the components are mounted together, the camera is encapsulated and housed, where it is placed inside tough materials such as aluminum or polycarbonate to offer weather resistance and dust protection, particularly for outdoor cameras. The firmware installation and testing phase comes next, where every camera is programmed, tested for video quality, night vision, and connectivity. Thermal, vibration, and durability tests are conducted to ensure safety and quality compliance. Once passed through quality control, cameras are packaged, labeled, and shipped. Much of today's production incorporates automation and robotics to maximize the efficiency and consistency of production. The end product is a high-tech surveillance device meant to provide high-definition, real-time coverage under most environmental conditions.

Raw Material Required:

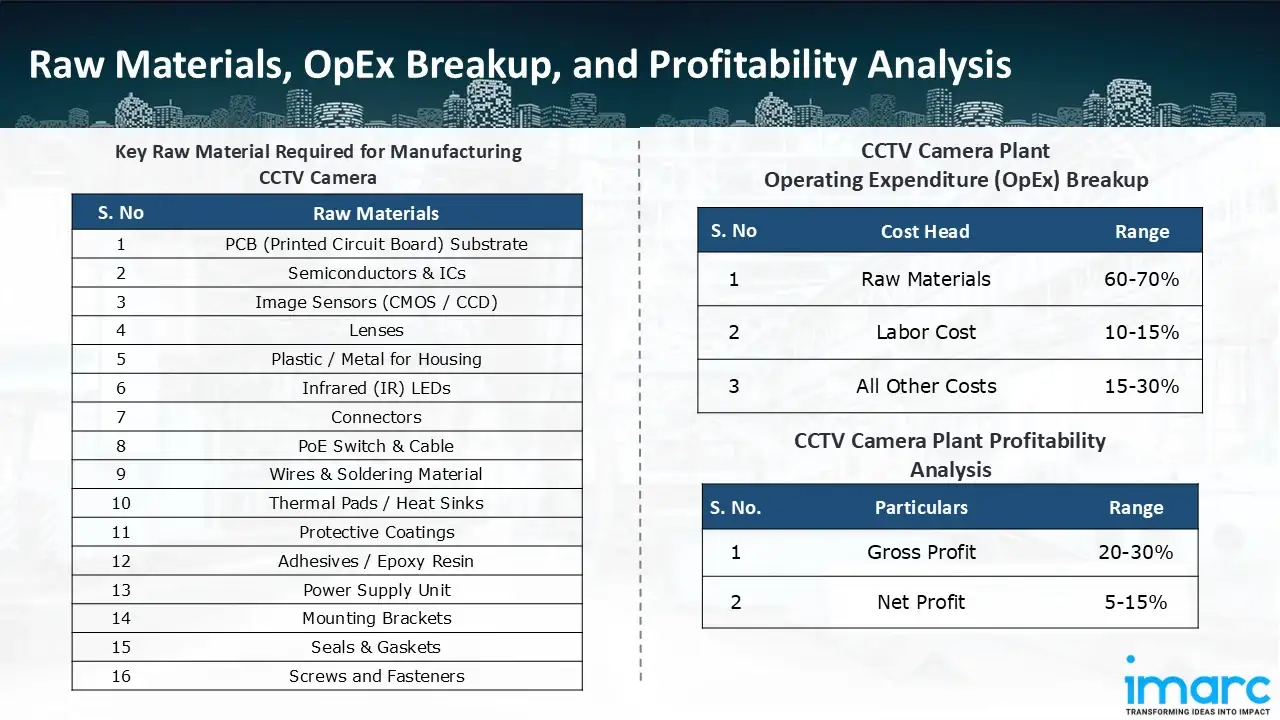

The basic raw materials required for CCTV camera manufacturing include:

- PCB (Printed Circuit Board) Substrate

- Semiconductors & ICs

- Image Sensors (CMOS / CCD)

- Lenses

- Plastic / Metal for Housing

- Infrared (IR) LEDs

- Connectors

- PoE Switch & Cable

- Wires & Soldering Material

- Thermal Pads / Heat Sinks

- Protective Coatings

- Adhesives / Epoxy Resin

- Power Supply Unit

- Mounting Brackets

- Seals & Gaskets

- Screws and Fasteners

Machineries Required:

- PCB Fabrication Machines

- Surface Mount Technology (SMT) Machines

- Reflow Oven

- Wave Soldering Machine

- Automated Optical Inspection (AOI) Systems

- Lens Molding Machines

- Precision Lens Grinding & Polishing Machines

- Sensor Mounting Jigs

- Injection Molding Machines

- CNC Machines

- Robotic Assembly Lines

- Sealing Machines

- Led Soldering Stations

- Testing Equipment

- Functional Test Jigs

- Environmental Chambers

- Vibration Test Equipment

- Network Testers

- Automatic Packaging Machines

- Shrink Wrapping Machines

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a CCTV camera manufacturing plant ranges between 60-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-30%, and net profit lie between the range of 5-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion:

Our financial model for the CCTV camera manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 120,000 units of CCTV camera annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104