Electric Bike Cost Model: E-Mobility Cost Intelligence

What is Electric Bike?

Electric bikes, commonly referred to as e-bikes, are one of the most transformational innovations in modern personal mobility, combining conventional bicycle mechanics with advanced electric propulsion technology. At the heart of e-bikes are an electric motor, a rechargeable battery, and a control system that add assistance to the rider while pedaling, making cycling easier, faster, and more accessible across varied terrains. Based on their design, they can be further categorized into pedal-assist, throttle-controlled, or hybrid models, each providing different levels of rider control and engagement of the motor. Advances in technology have greatly improved e-bike performance, from the development of lightweight lithium-ion batteries and brushless motors to smart connectivity features.

Key Applications Across Industries:

These improvements have extended their use from commuting in urban centers to mountain biking, cargo transport, and even applications of delivery services. Beyond convenience, e-bikes also address global environmental concerns by reducing dependence on fossil-fuel-based transport, thus lowering greenhouse gas emissions and urban air pollution. They also cater to the health-conscious consumer, looking for sustainable exercise with reduced physical strain. Today, manufacturers are looking at ergonomic design, modular batteries, and integrated digital interfaces such as GPS tracking and app-based diagnostics. The global shift towards sustainable mobility, supported by government incentives, urban infrastructure developments, and increased awareness of climate change, has positioned e-bikes as a critical component of the future transportation ecosystem. With ongoing innovation in materials, energy efficiency, and smart technology integration, electric bikes continue to redefine personal transport by offering a balance between sustainability, performance, and convenience.

What the Expert Says: Market Overview & Growth Drivers

The global electric bike market reached a value of USD 26.4 Billion in 2024. According to IMARC Group, the market is projected to reach USD 45.5 Billion by 2033, at a projected CAGR of 6.22% during 2025-2033. This market is driven by technological, environmental, and socioeconomic drivers aligned with the broader sustainable urban mobility trends. Among the leading factors is the global commitment to reducing carbon emissions and promoting congestion-free traffic in cities. With cities encouraging eco-friendly transportation alternatives, e-bikes have emerged as a practical solution for short- to mid-range commutes.

Advances in battery technology, especially lithium-ion and solid-state batteries, have greatly improved energy density, charging speed, and cycle life, further making e-bikes more reliable and consumer-friendly. Surging fuel prices and increased awareness of climate change concerns are thus driving both individuals and governments toward electric mobility solutions. Furthermore, changing consumer lifestyles, especially in highly populated cities, create demand for compact, affordable, and low-maintenance transportation options. In this regard, e-bikes cater to these needs while offering flexibility in use across various age groups. Shared mobility services and e-bike rental platforms have further surged the adoption, especially in Europe and Asia. Health-conscious consumers are also realizing the value of an e-bike for exercise on an assisted pedaling platform, blending fitness with convenience. Governments worldwide are supportive of the market with incentives, subsidies, and infrastructural investments in the form of dedicated cycling lanes and charging stations. Finally, integration with digital technologies such as IoT-enabled tracking systems and smartphone connectivity has raised the user experience and safety. All these aspects underline a strong and continuous growth trajectory of the global e-bike industry as the world moves toward greener, smarter, and efficient mobility solutions.

Case Study on Cost Model of Electric Bike Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale electric bike manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed electric bike manufacturing plant in India. This plant is designed to manufacture 15,000 units of electric bike annually.

Manufacturing Process: The electric bike manufacturing process incorporates the traditional methods of bicycle production along with modern electrical and electronic engineering, thus resulting in an efficient, durable, and high-performance mobility solution. The whole process typically commences with design and prototyping: computer-aided design models are created by the engineers or designers to optimize geometrical frame design, aerodynamics, and motor integration. The actual manufacturing of frames consists of materials such as an aluminum alloy, carbon fiber, or steel, which are selected based on strength-to-weight efficiency. All frame components are cut, welded, and then heat-treated to ensure structural rigidity. The next step is surface treatment and painting of the frame, usually using powder coating or anodizing for corrosion resistance and aesthetic appeal. Meanwhile, the electric drivetrain is being prepared concurrently with mechanical assembly: integration of the electric motor-in-the-hub, mid-drive, or rear-wheel-and the battery pack, normally made up of lithium-ion cells encased in a protective casing. Installation of the motor controller and wiring harness follows to manage power delivery, torque, and regenerative braking functions. In the course of assembly, the mechanical components-wheels, gears, brakes, suspension, and handlebars-are fitted to ensure functionality and comfort. The integration of the BMS and sensor integration continues with the addition of speed sensors, torque sensors, and displays. Performance is regulated and monitored by those displays. Next, the e-bike undergoes extensive quality control, with load testing, range assessment, verification of electrical safety, and waterproofing. Once cleared, the e-bikes are packaged and distributed to retailers or sold directly. The whole process emphasizes precision engineering, lightweight construction, and electrical reliability in every unit, built to safety standards for optimal performance.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

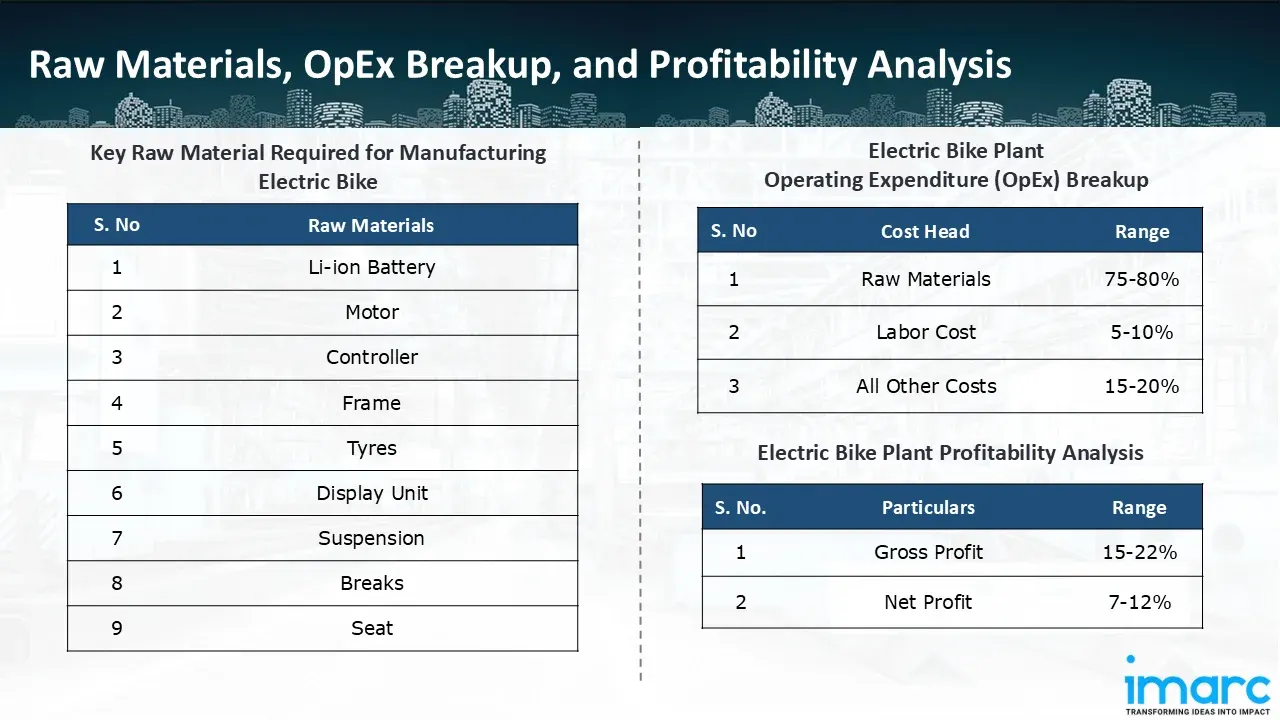

The basic raw materials required for electric bike manufacturing include:

- Li-ion Battery

- Motor

- Controller

- Frame

- Tyres

- Display Unit

- Suspension

- Breaks

- Seat

Machineries Required:

- Frame Fabrication

- Painting

- Assembly Line

- Testing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in electric bike manufacturing plant ranges between 75-80%, labor cost ranges between 5% to 10%, and all other costs ranges between 15-20% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-22%, and net profit lie between the range of 7-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the electric bike manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 15,000 units of electric bikes annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In April 2025, the brand-new RadRunner, RadRunner Plus, and RadRunner Max are three all-purpose cargo e-bikes that represent the next generation of the beloved RadRunner lineup, according to Rad Power BikesTM. Rad Power Bikes has been leading the way in electric bike innovation since the first Rad ebike was constructed in a garage in Northern California in 2005.

- In March 2025, TVS Motor Company, through its wholly owned Singapore subsidiary, has announced the purchase of an additional 8.26% share in The GO Corporation (GOAG), a Swiss-based provider of e-mobility services. Through this deal, TVS Motor (Singapore) Pte Ltd will become a fully owned subsidiary of GOAG, increasing its stake to 100%.

- In January 2025, the e-bike division of Pierer Mobility AG, Pierer New Mobility GmbH, has announced that it will phase down its activities in South Africa, Germany, and the UK and consolidate its operations to headquarters in Munderfing, Austria, and Murrieta, California.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and esign of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104