Pavers Block Manufacturing Cost Analysis: Building Value, One Block at a Time

What is Pavers Block?

Paver blocks are precast construction material made basically from cement, aggregates, sand, and pigments for constructing surfacing. They are produced in standardized shape and thickness, allowing each unit to interlock to form a strong, load-bearing surface with no need for continuous concrete pouring. Paver blocks possess high compressive strength, abrasion resistance, and are easy to lay and maintain. Their modular nature allows damaged units to be replaced easily, making them a practical and cost-effective alternative to traditional asphalt or cast-in-place concrete pavements.

Key Applications Across Industries:

Paver blocks have wide applications in residential, commercial, industrial, and infrastructure projects, all because of their strength, flexibility, and aesthetic appeal. For instance, their application in residential settings includes driveways, walkways, patios, garden paths, parking lots, and courtyards. They come in a variety of colors, shapes, and surface finishes, enabling homeowners and developers to add beauty to the outdoors while ensuring strength and anti-skid properties.

Paver blocks find their applications in shopping complexes, office campuses, hotels, hospitals, and educational institutions for purposes such as internal roads, pedestrian walkways, and parking spaces within commercial and institutional setups. They can withstand moderate vehicular loads and a high volume of foot traffic, hence their suitability for high-usage areas. Heavy-duty paver blocks are utilized in factory yards, warehouses, logistics parks, and loading zones within industrial facilities, where there is a need for resistance against abrasion, oil spills, and mechanical stress.

Another huge service sector for this product is infrastructure and public-space applications. Municipal corporations erect paver blocks in footpaths, sidewalks, bus stops, railway platforms, plazas, and public parks. An upsurge has been noticed in the permeable and hollow designs of pavers in stormwater management systems to support groundwater recharge and minimize surface runoff. In addition, paver blocks are used in ports, airports, container yards, and fuel station areas where durability and less maintenance cost are required. On the whole, owing to their adaptability, they find extensive applications both in functional and decorative needs of paving.

What the Expert Says: Market Overview & Growth Drivers

The global pavers block market reached a value of USD 4.60 Billion in 2024. According to IMARC Group, the market is projected to reach USD 7.14 Billion by 2033, at a projected CAGR of 5.0% during 2025-2033. The global paver block market is driven by expanding urban infrastructure, increased construction activity, and growing emphasis on sustainable and modular paving solutions. Rapid urbanization in the emerging economies of the world acts as a strong driver, with cities investing heavily in roads, footpaths, parking, public areas, and residential areas. Paver blocks provide a cost-effective, long-lasting solution for such projects, specifically where phased construction and easy maintenance are called for.

The demand significantly arises from governmental infrastructural development programs. Pedestrian-friendly street projects by municipalities, smart cities, urban renewal, and beautification commonly feature the use of paver blocks due to their flexibility in design and ease of laying. Their appropriateness for repairs and access to utilities further enforces their application in urban sectors. In the industrial and logistics sector, the expansion of warehouses, manufacturing plants, and transportation hubs increases demand for high strength paving solutions that can withstand high loads.

Market growth is increasingly related to considerations of sustainability. Permeable paver blocks maintain water management and flood mitigation policies through the infiltration of rainwater into the ground. Accordingly, the production of permeable paver blocks with recycled aggregates, industrial by-products, and waste materials is also attracting more manufacturers, since this aligns with circular economy goals and support regulatory compliance.

The other principal factor is increasing awareness of lifecycle cost benefits. In contrast to asphalt or monolithic concrete, paver blocks boast longer service life, lower maintenance costs, and easier replacement. The increased aesthetic customization and color stability also enhance their demand in high-status residential and commercial properties.

Manufacturing technological improvements include automated block-making machines, vibration compaction, and precision molds that improved quality consistency and production efficiency. Taken altogether, these forces of urban growth, investment in infrastructure, sustainability mandates, and technological advancement propel the sustained global demand in the manufacture of paver blocks.

Case Study on Cost Model of Pavers Block Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale pavers block manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed pavers block manufacturing plant in India. This plant is designed to manufacture 2 million sq. ft. of pavers block annually.

Manufacturing Process: The manufacture of paver blocks essentially comprises a series of processes in material preparation, compaction, curing, and finishing to produce high-strength, accurate-dimensional paving units. Production starts with the selection of appropriate raw materials, such as cement, graded aggregates, sand, pigments, and water. All these raw materials have to be weighed precisely and mixed in controlled proportions with the help of pan or planetary mixers to ensure uniformity in consistency and color. In some cases, admixtures are added to improve workability, early strength, or surface finish. It is then fed into the automatic paver block machines, which pour the ready mix into the precision-engineered molds corresponding to the desired block shape and thickness. Simultaneously, vibration and hydraulic compaction remove air voids to achieve high density for strength and durability. A base layer is compacted first in dual-layer paver blocks, followed by a finer, pigmented top layer to enhance surface appearance and wear resistance. After molding, the green paver blocks are carefully transported either to curing chambers or stacked in controlled environments. Curing is normally done using a water spray, steam curing, or systems that keep moisture at controlled conditions over a specified period of time to allow for adequate hydration of cement and development of strength. The blocks, after curing, were taken out of the molds and hardened further under natural conditions. The blocks are checked for dimensions, compressive strength, and water absorption, including surface finish, through quality-control inspections. Blocks that are approved are palletized, packaged, and stored for distribution. Modern manufacturing plants are already incorporating automation techniques, quality monitoring systems, and sustainable material handling practices to enhance efficiency, consistency, and environmental performance.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

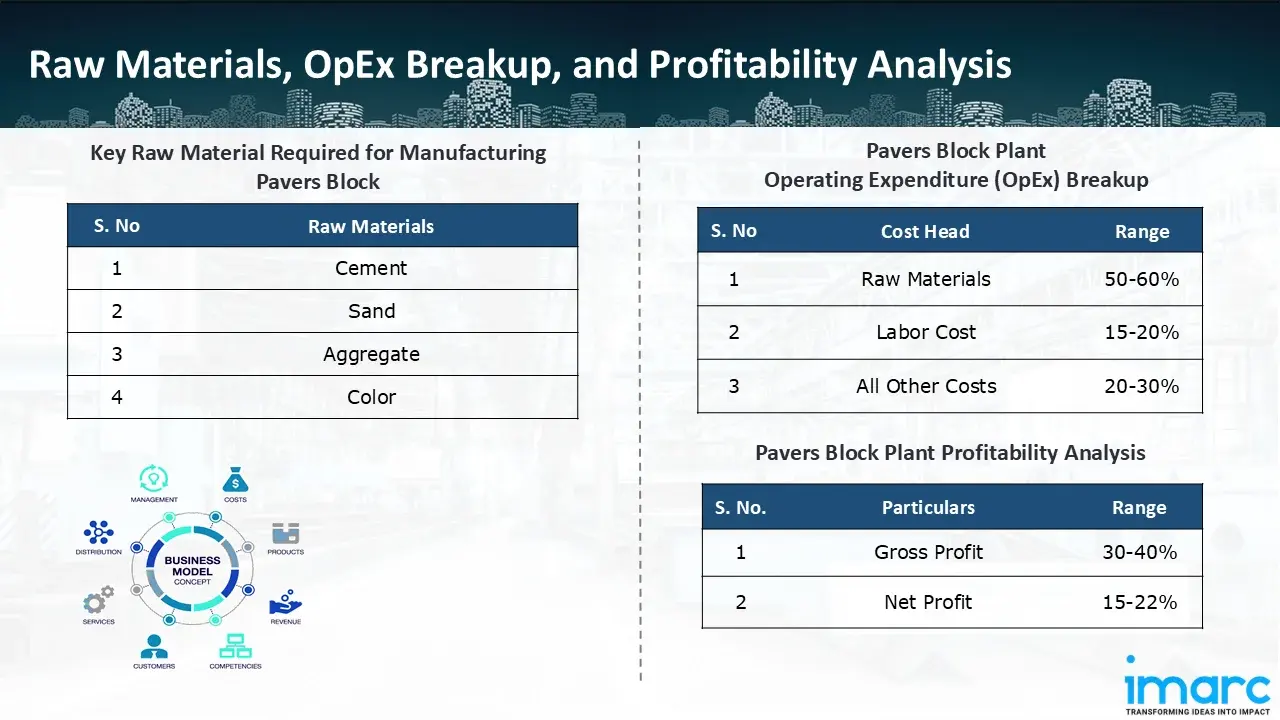

The basic raw materials required for pavers block manufacturing include:

- Cement

- Sand

- Aggregate

- Color

Machine Section or Lines Required:

- Mixer

- Vibrating Table

- Curing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in pavers block manufacturing plant ranges between 50-60%, labor cost ranges between 15% to 20%, and all other costs ranges between 20-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 15-22% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the pavers block manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 2 million sq. ft. of pavers block annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In August 2025, road construction equipment manufacturer Ammann India announced that it has launched its first tracked asphalt paver from its recently constructed manufacturing line at its Gujarati site in Ditasan.

- In June 2024, the Indian government's patent office has awarded a patent to a Mysuru-based business named Jagruth Tech for its ground-breaking eco-friendly interlocking paving block. A product made of non-recyclable plastic and Refuse Derived Fuel (RDF) has never before been granted a patent.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104