Philippines Conveyor Belt Industry Embraces IoT and AI Integration with New Investments

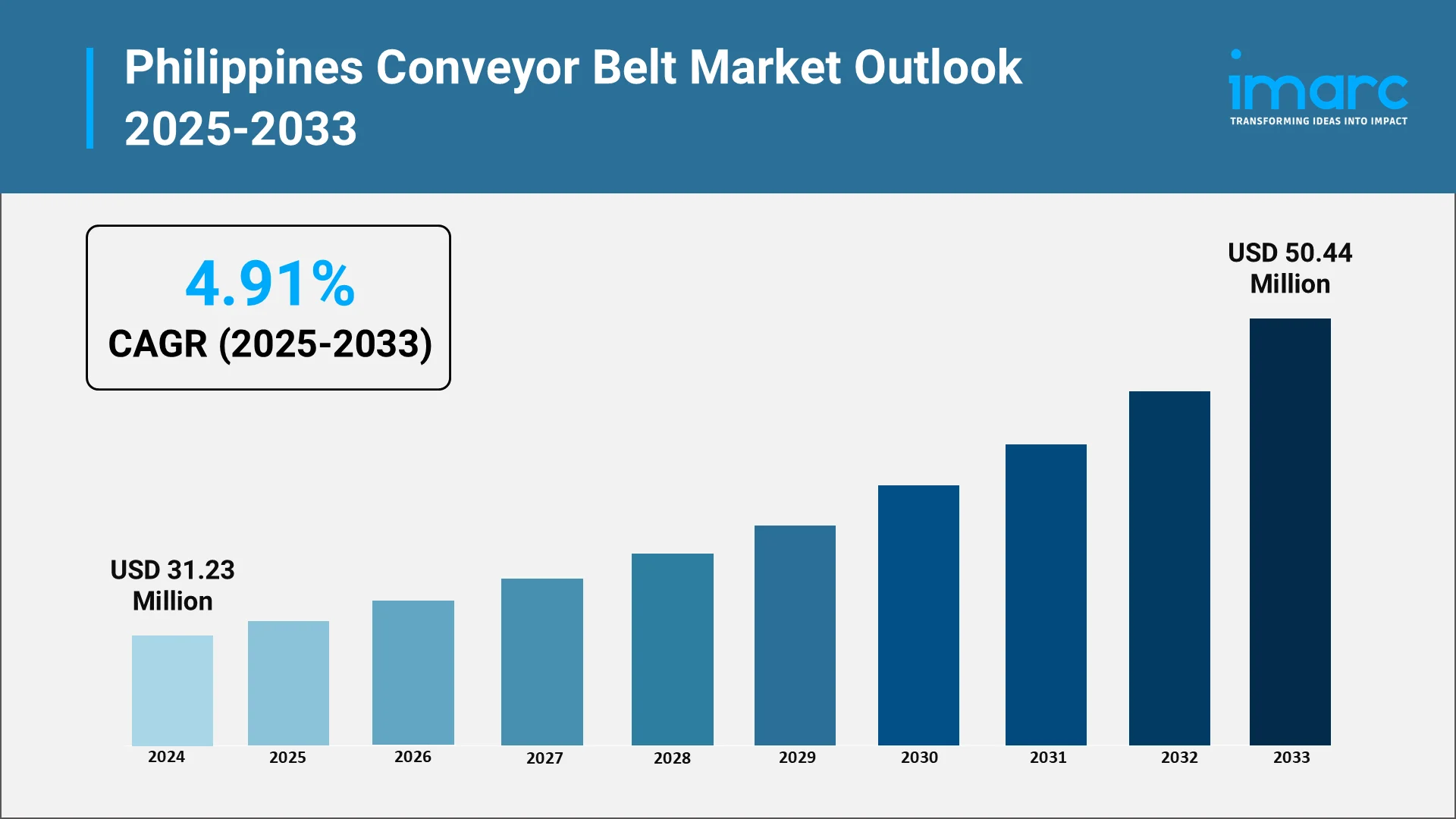

The Philippines conveyor belt market is picking up speed, powered by the country’s industrial growth and focus on automation. According to the IMARC Group, the market reached USD 31.23 Million in 2024, reflecting notable growth across manufacturing, mining, logistics, and food processing. As industries modernize, the need for efficient material handling systems is creating strong momentum for both domestic and imported conveyor solutions.

Innovation is also reshaping how conveyor systems operate. Artificial intelligence (AI), sensors, and predictive maintenance tools are helping businesses track performance, prevent breakdowns, and optimize production flows. These technologies are improving reliability, cutting energy use, and extending equipment life, making the Philippines conveyor belt market a key contributor to the country’s evolving industrial landscape.

Explore in-depth findings for this market, Request Sample

When Machines Think: AI’s Influence on Conveyor Belt Technology

AI is revolutionizing the conveyor belt sector in the Philippines by embedding automation, enhancing efficiency, and providing predictive functionalities throughout production and logistics processes. By utilizing real-time data analysis and machine learning, AI enables companies to minimize downtime, enhance performance, and fulfill sustainability objectives, reinforcing the industry’s contribution to the nation’s industrial advancement.

- Smarter Maintenance for Smoother Operations: AI improves conveyor system efficiency by forecasting maintenance requirements prior to any breakdowns. By gathering data from sensors and monitoring systems, AI detects wear trends, lowering unexpected downtime and maintenance expenses. This proactive method guarantees uninterrupted functions, prolongs equipment durability, and greatly enhances overall plant efficiency and dependability.

- Redefining Efficiency Through Automation: Automation powered by AI allows manufacturers to enhance production processes by assessing system efficiency as it occurs. The speed of the conveyor, distribution of the load, and flow of materials can be automatically modified to ensure maximum output. This degree of accuracy enhances productivity, energy efficiency, and minimizes operational mistakes in sectors like manufacturing, logistics, and food processing.

- Smart Monitoring in Action: AI is essential in enhancing quality assurance throughout conveyor systems. Algorithms in machine learning (ML) can identify anomalies in product movement, belt positioning, or component functionality. This immediate fault identification reduces waste, improves product uniformity, and enables firms to uphold high production standards while ensuring safety in the workplace and operational integrity.

- Intelligence with Purpose: AI applications deliver practical insights via sophisticated data analysis, aiding strategic choices in system design, energy usage, and resource distribution. AI aids companies in implementing sustainable practices by overseeing energy usage and operational efficiency. These insights encourage cost reduction, adherence to environmental regulations, and sustainable competitiveness in the conveyor belt sector of the Philippines.

Meet the Movers: Leading Conveyor Belt Brands of the Philippines

Major participants in the Philippines conveyor belt industry are concentrating on enhancing their technological skills, raising product standards, and bolstering their regional presence. Numerous individuals are putting their money into cutting-edge materials, including heat-resistant and energy-efficient belts, to address the growing demand from sectors like mining, cement, manufacturing, and food processing. For instance, in 2025, Kaifeng Iron Tower Rubber (Group) Co., Ltd. delivered 880 meters of customized conveyor belts to Philippine cement producer Century Peak Corp. (CPC). The belts, tailored for high-temperature and high-dust environments, were produced and shipped 15% faster than industry norms. This deal supports regional infrastructure under the Belt and Road Initiative, with plans for a Manila-based service center. Moreover, collaborative partnerships with automation and sensor tech providers are enabling the integration of intelligent monitoring and predictive maintenance systems, improving reliability and minimizing operational downtime. These firms are prioritizing sustainability through the use of environment-friendly materials and improving production methods to minimize energy usage and waste. To gain a larger market share, producers and suppliers are broadening their service networks, providing customization, and enhancing post-purchase assistance.

Turning Friction into Force: Prospects and Pressures in Conveyor Belt Operations

The conveyor belt industry in the Philippines is experiencing significant opportunities driven by infrastructure growth and automation in vital areas like mining, logistics, and food processing. Increasing demand for effective material handling systems, along with governmental support for modernization of manufacturing, is driving investments in advanced conveyor technologies, eco-friendly materials, and local production capabilities. This industry growth, influenced by infrastructure and manufacturing modernization, is exemplified by Taiheiyo Cement Philippines inaugurating a new 3Mt/yr production line at its Cebu plant in 2024. As part of a US$220 million upgrade, the project included a marine belt conveyor linking the plant to the coast, improving logistics efficiency. This move aligns with the government’s infrastructure drive and support for local manufacturing under the Tatak Pinoy Act.

Although there is positive market outlook, the industry encounters difficulties like a heavy reliance on imported raw materials, varying prices for steel and rubber, and inadequate local manufacturing infrastructure. Operational constraints are further compounded by maintenance expenses, energy usage, and the requirement for qualified technical staff. Tackling these challenges with innovation, employee training, and sustainable manufacturing methods is crucial for enduring market stability.

The Pulse of Progress: Factors influencing the Philippines Conveyor Belt Industry

According to IMARC Group’s projections, the Philippines conveyor belt market is projected to grow at a CAGR of 4.91% from 2025 to 2033, reaching USD 50.44 Million by 2033. The growth will be supported by the following factors:

- Rock Solid Growth: Conveyor Belts in Mining and Quarrying

The consistent rise in mining and quarrying operations in the Philippines is creating a robust need for durable and high-performance conveyor belt systems. These systems are crucial for the effective and ongoing movement of bulk materials like ores, limestone, and aggregates, guaranteeing seamless operations and improved safety at extraction and processing locations. With the rising opportunities in the sector, mining firms are progressively allocating resources to modern conveyor systems built to endure severe environmental conditions, lessen energy usage, and enhance material handling efficiency. A significant advancement supporting this trend took place in 2024, when Makilala Mining Company received the nation’s inaugural copper mining permit for the Maalinao-Caigutan-Biyog (MCB) Project in the Cordilleras through a 25-year Mineral Production Sharing Agreement that encompasses 2,500 hectares. This milestone highlighted the growing need for conveyor solutions for enhancing large-scale mineral operations, boosting productivity, and aligning the sector with worldwide standards of safety, sustainability, and operational excellence.

- Intelligent Manufacturing: Where Automation Meets Efficiency

The incorporation of automation and smart technologies is revolutionizing the performance and effectiveness of conveyor belt systems throughout the Philippines. AI and Internet of Things (IoT) technologies are facilitating real-time performance tracking, automatic speed control, and predictive maintenance functionalities. These innovations minimize operational downtime, enhance resource utilization, and prolong equipment lifespan by detecting possible problems before failures arise. Intelligent sensors and cloud-driven data analysis enable businesses to monitor energy use and enhance the precision of their decision-making. With industries adopting Industry 4.0 principles, the implementation of automated and interconnected conveyor systems is emerging as a crucial requirement for sustaining competitiveness, improving accuracy, and fostering sustainable industrial advancement in the nation's changing manufacturing environment.

- Building the Nation: Conveyors in Infrastructure Expansion

The ongoing expansion of infrastructure projects across the Philippines, spanning from ports, highways, industrial zones, to logistics hubs, is significantly accelerating the adoption of conveyor systems. Construction companies and engineering contractors are increasingly integrating advanced conveyor technologies to transport raw materials efficiently, thereby minimizing labor dependency, operational downtime, and costs. These systems enhance workflow coordination, improve safety, and support faster project execution across large-scale development sites. A notable example is Terratec’s deployment of two 1,509-meter Continuously Advancing Conveyors in 2024, for tunnel boring machine (TBM) operations under Lot CP101 of the Metro Manila Subway Project. Each conveyor was equipped with Variable Voltage Variable Frequency (VVVF) motor control and hydraulic tensioning, enabling a handling capacity of up to 225m³ per hour of excavated material. Such technological integration highlights how infrastructure modernization efforts are encouraging the use of high-performance conveyor systems, reinforcing the country’s commitment to efficiency, innovation, and sustainable industrial progress.

- Efficiency in Every Move: Energy-Smart Conveying Systems

Producers are creating lightweight, energy-saving models featuring enhanced motors to reduce energy use and operational expenses. The growing usage of recyclable materials, water-based glues, and eco-friendly manufacturing techniques is lowering the sector’s carbon footprint. Businesses are progressively coordinating their operations with international environmental benchmarks to guarantee adherence and international competitiveness. Government support for green technologies is further supporting this change, motivating companies to implement eco-friendly conveyor systems that harmonize efficiency with environmental responsibility.

- From Dock to Dispatch: Conveyors Powering Modern Warehouses

The robust Philippines e-commerce market and logistics sectors are catalyzing the demand for automated conveyor systems. These systems are becoming vital components in ensuring the smooth handling, sorting, and movement of goods within warehouses, packaging units, and large-scale distribution facilities. Conveyor belts enable faster material flow, minimize human error, and improve operational precision, which are crucial for meeting the growing expectations of speed and reliability in the country’s supply chains. A notable development reinforcing this trend is Maersk’s inauguration of its largest Philippine distribution center in 2024, a ten-hectare facility located in Calamba, Laguna, equipped with a 76,000-pallet capacity and state-of-the-art logistics technology. Facilities of this scale enhance automation, streamline logistics efficiency, and stimulate economic growth across Southern Luzon, CALABARZON, and Bicol. As e-commerce expands, such advancements will continue to elevate the country’s supply chain capabilities, thus driving the demand for conveyor belts for smooth operations.

- Tailored for Performance: The Era of Custom Conveyor Solutions

Producers in the Philippines conveyor belt sector are progressively allocating resources towards the creation of innovative materials and tailored designs to improve efficiency, longevity, and durability. Advancements like heat- and chemical-resistant composites, flame-resistant rubbers, and environment-friendly synthetic materials are enhancing operational reliability and lowering energy usage. Customization is becoming crucial as sectors like mining, food processing, and pharmaceuticals need belts tailored for specific applications that can endure varying temperature, load, and sanitation requirements. These customized solutions guarantee operational accuracy while also lowering maintenance expenses and downtime. Through an emphasis on innovation, manufacturers are enhancing their competitiveness and addressing the varied technical needs of an expanding and technologically advanced market.

Turning Insights into Action: IMARC’s Market Roadmap

IMARC Group empowers stakeholders in the Philippines conveyor belt industry with data-driven intelligence to navigate a rapidly industrializing economy. Our research and consulting services help clients uncover emerging opportunities, address operational challenges, and strengthen competitiveness through innovation, efficiency, and sustainability.

- Market Insights: Track trends influencing the Philippines conveyor belt market, including the growing demand from manufacturing, mining, logistics, and food processing sectors. Understand the impact of automation, industrial expansion, and material innovation on product adoption and performance.

- Strategic Forecasting: Anticipate technological advancements in belt materials, energy efficiency, and smart monitoring systems, alongside developments in local production, export competitiveness, and industrial modernization.

- Competitive Intelligence: Evaluate strategies, product portfolios, and innovation pipelines of leading conveyor belt manufacturers and suppliers, along with emerging players investing in cost-effective and durable solutions.

- Policy and Regulatory Analysis: Gain clarity on trade policies, import duties, quality certifications, and environmental compliance regulations shaping the production and distribution of conveyor systems in the Philippines.

- Tailored Consulting Solutions: Access customized guidance on market entry, product diversification, supply chain optimization, and technology integration. IMARC’s consulting expertise enables clients to build efficient, scalable, and sustainable operations aligned with the country’s industrial growth.

As the Philippines conveyor belt market continues to grow across key industries, IMARC Group remains a trusted partner, providing actionable insights and strategic solutions that drive performance, resilience, and long-term growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104

.webp)