Electric Scooter Cost Model: Market Profit Outlook

What is Electric Scooter?

An electric scooter is a two-wheeled vehicle powered by an electric motor and rechargeable battery, aimed at offering the means for efficient, eco-friendly, and cost-effective urban mobility. Apart from the traditional scooters that are powered by internal combustion engines, the electric scooters make use of lithium-ion or lead-acid batteries that feed an electric supply to a BLDC motor, which drives the wheels either directly or via a belt or chain mechanism. The main components comprise the electric drivetrain, controller, BMS, regenerative braking setup, and an onboard digital dashboard showing speed, battery level, and riding modes.

Key Applications Across Industries:

Typically, electric scooters are divided into categories of speed and power-low-speed ones, for city commuting, and high-performance variants for longer distances or even commercial purposes. The continuous evolution of electric scooters has been driven by improvements in the efficiency of batteries, lightweight materials, and integration with electronic components. Modern models boast smart connectivity with IoT-enabled diagnostics, GPS tracking, remote locking, and integration with a mobile app for real-time performance insights. Also, regenerative braking systems and swappable battery modules increased range and convenience. Electric scooters are designed to cater to a wide range of customers: private consumers, fleet operators, and last-mile delivery services. Compact design, minimal maintenance, and silent operation make electric scooters ideal for densely populated urban cities. As the world's major cities emphasize sustainable transportation and support entry of only those vehicles that adhere to strict emission norms, electric scooters have become a key game-changing component in this evolution toward clean and connected mobility. Innovation in mobility, digital technology, and environment-based consciousness continues to alter the way people and businesses think about short-distance transportation.

What the Expert Says: Market Overview & Growth Drivers

The global electric scooter market reached a value of USD 41.21 Billion in 2024. According to IMARC Group, the market is projected to reach USD 92.15 Billion by 2033, at a projected CAGR of 9.4% during 2025-2033. The global electric scooter market has been propelled by several environmental, technological, and socio-economic factors combined, hence aligning with the worldwide transition toward sustainable mobility. Amongst the drivers is the growing global impetus toward reducing carbon emissions and fostering lesser dependence on fossil fuels. Governments are imposing stricter environmental regulations and offering incentives for electric vehicle adoption through subsidies, tax reductions, and investments in charging infrastructure. Electric scooters, due to their compactness and energy efficiency, fit perfectly in this paradigm by offering zero tailpipe emissions and lower lifecycle costs. Other causes for the high demand for electric scooters are rapid urbanization and traffic congestion, both growing in most cities, where compactness, agility, and quick parking become essential.

Furthermore, improvements in battery technology, specifically lithium-ion chemistry, have enabled great strides in terms of range, charging speed, and overall performance; e-scooters are viable options both for personal mobility and commercial fleet applications. The introduction of swappable and fast-charging battery systems has made them even more practical for delivery and ride-sharing fleets. Another significant growth driver is the growing usage of shared mobility platforms. Electric scooter-sharing services will gain traction across major cities in Asia, Europe, and North America, promoting better access and reducing ownership barriers. Besides, the continued rise in the prices of petroleum-based fuels has made electric mobility a more economic option for daily commuters. Integration of technologically advanced features-such as smartphone-based navigation, over-the-air software updates, and predictive maintenance-has also enhanced user convenience and engagement. Put together, all these factors, along with attitude shifts by consumers toward sustainability and economy, will shape the global expansion of electric scooters, making them a mainstay of future urban transportation ecosystems.

Case Study on Cost Model of Electric Scooter Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale electric scooter manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed electric scooter manufacturing plant in India. This plant is designed to manufacture 50,000 units of electric scooter annually.

Manufacturing Process: The manufacturing process for an electric scooter requires a complex interplay of mechanical engineering, electrical integration, and quality control for performance, safety, and durability. The process commences with product design and prototyping, wherein the engineers develop detailed CAD models to optimize frame geometry, weight distribution, and motor placement. Once this stage is wrapped up, the fabrication of the frame is started with materials like aluminum alloy, steel, or reinforced composite material. All the components of the frame are laser-cut, welded, and heat-treated to attain strength with minimum weight. After fabrication, the frame is sanded, coated, and painted to resist corrosion and enhance aesthetics. At the same time, the electrical parts-the motor, controller, and battery-are being prepared. The electric motor is usually of BLDC type and is mounted on the hub or mid-section according to the design of the scooter. The battery pack, typically assembled from lithium-ion cells, is combined and tested with a BMS for the purpose of balancing charging, thermal protection, and durability. The electronic controller is programmed to control power flow and throttle response. These electrical units are then assembled into the chassis, with wiring harnesses correctly routed for safety and reliability. Further, it installs mechanical units like wheels, brakes, suspension, and steering assemblies. Advanced models are fitted with digital dashboards, IoT modules, and regenerative braking systems. After the complete installation, scooters go through severe tests that include performance, vibration, waterproofing, and verification of their braking efficiency. Finally, after inspection and certification for quality, the scooters are packed and dispatched. This accurate and multi-stepped manufacturing process ensures that every electric scooter gives exemplary efficiency, comfort, and reliability while conforming to the global standards of safety and sustainability.

Get a Tailored Feasibility Report for Your Project Request Sample

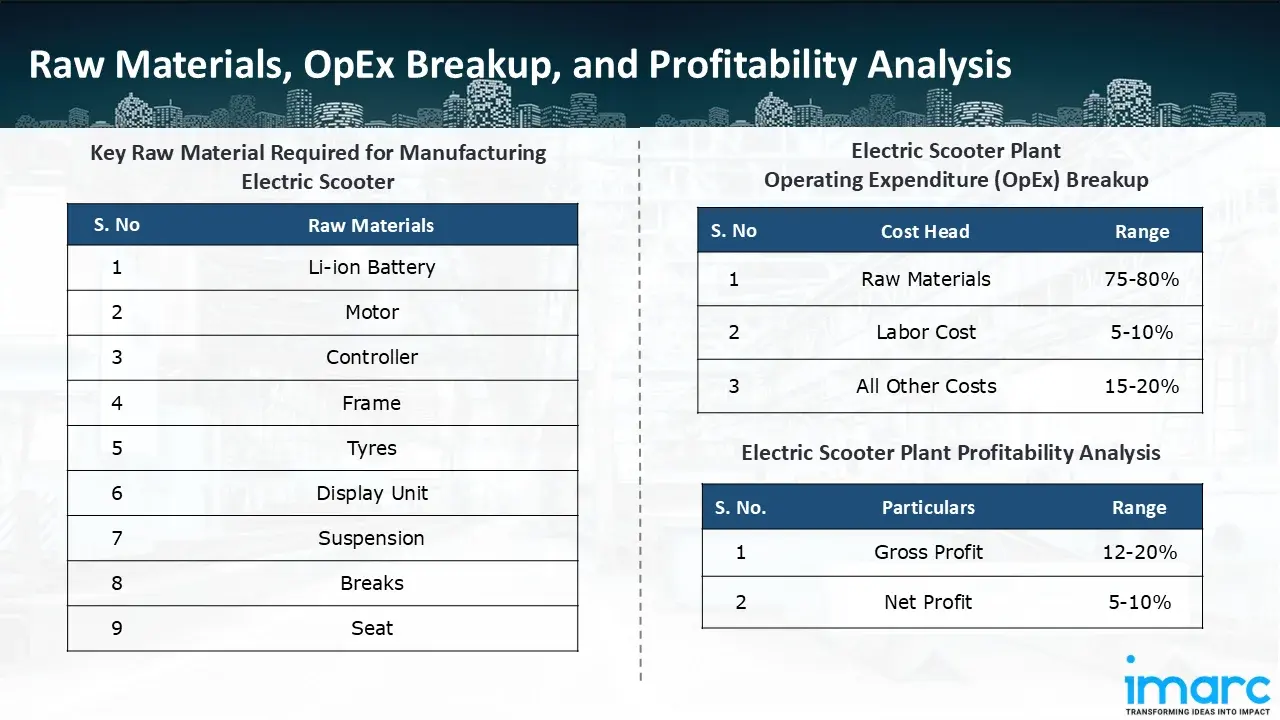

Raw Material Required:

The basic raw materials required for electric scooter manufacturing include:

- Li-ion Battery

- Motor

- Controller

- Frame

- Tyres

- Display Unit

- Suspension

- Breaks

- Seat

Machineries Required:

- Chassis Fabrication

- Body Molding

- Assembly Line

- Testing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in electric scooter manufacturing plant ranges between 75-80%, labor cost ranges between 5% to 10%, and all other costs ranges between 15-20% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 12-20%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the electric scooter manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 50,000 units of electric scooters annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, Simple Energy, which is well-known for its sporty electric scooter, the Simple One, announced that it would be adding a new family-friendly e-scooter to its lineup for daily-use application. The company has submitted a design patent for the next model, indicating a possible rival to the Ather Rizta in the high-end urban scooter market.

- In August 2025, Ola Electric introduced a motor devoid of rare earth metals and its first in-house 4680 Bharat cell battery. Included in the launch lineup was the new S1 Pro+ scooter with the upgraded battery. Additionally, the business released MoveOS 6, which has more functionality. The S1 Pro Sport scooter and an electric bike will be introduced by Ola in 2026 and 2027, respectively.

- In July 2025, ZELIO E Mobility introduced the redesigned Eeva, which was priced at INR 50,000 and had enhanced comfort, performance, and smart features. Gel and lithium-ion batteries are among the various battery combinations available for the upgraded Eeva.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104