Nicotine Pouches Manufacturing Cost Analysis: Economics in Every Pouch

What are Nicotine Pouches?

Nicotine pouches are small, smokeless oral delivery products of nicotine, free from tobacco, designed to allow for controlled release of the active principle without burning, vaporizing, or use of traditional tobacco leaves. It consists of a small pouch that contains a matrix made basically from plant fibers, flavorings, pH adjusters, and stabilizers impregnated with nicotine, encased in a permeable material permitting the gradual absorption of the product via the oral mucosa. Nicotine pouches are placed between the gum and the lip, providing a discreet, spit-free experience. Their design supports consistent dosing, flavor variety, and reduced sensory irritation compared to traditional smokeless tobacco products, making them an increasingly attractive alternative for adult nicotine users seeking smoke-free options.

Key Applications Across Industries:

Nicotine pouches have a variety of uses for different consumer nicotine-use preferences, life-style needs, and harm-reduction contexts. Mainly, they are used to deliver nicotine without smoke and vapor, to meet the need of the adult consumer who wishes to avoid combustion-based tobacco products, such as cigarettes, or heated-tobacco products. Because nicotine pouch products do not produce smoke, smell, or any visible aerosol, they also become very widely used in places where smoking and vaping is restricted, such as in workplaces, public transport, hospitality venues, and outdoor events. Their discreet nature allows users to maintain nicotine intake without drawing attention; hence, they will be particularly appealing to people who value convenience and subtlety.

Flavored varieties, from mint and citrus to coffee, berry, and other customized flavor mixes, allow for personalization and sensory pleasure, which contributes to consumer involvement. Lower-, medium-, and high-strength pouch ranges also accommodate different nicotine tolerances and usage objectives, including gradual reduction for some adult consumers attempting to lessen dependence. Regarding sports and outdoor activities, nicotine pouches do not interfere with breathing, hand mobility, or performance, unlike smoking or vaping.

Retailers, convenience stores, and online platforms often frame nicotine pouches within a holistic nicotine portfolio, which would enable adult users to switch between product type as per the situational preference. The same format is employed by manufacturers for controlled release in order to enable predictable nicotine delivery, enhancing user experience and product consistency.

What the Expert Says: Market Overview & Growth Drivers

The global nicotine pouches market reached a value of USD 3.20 Billion in 2024. According to IMARC Group, the market is projected to reach USD 28.16 Billion by 2033, at a projected CAGR of 27.39% during 2025-2033. Some of the major drivers for global nicotine pouches include changing consumer preferences, regulatory developments, harm-reduction trends, and product innovation. A key driver lies in the move away from traditional combustible tobacco, as adult consumers seek out alternatives that reduce odor, lower social stigma, and become more convenient. Nicotine pouches meet the requirements of the modern lifestyle since they are discreet, portable, and can be used in smoke-free environments, joining a broader movement of society toward cleaner, non-combustion nicotine delivery formats. Secondly, the awareness regarding health hazards associated with smoking has compelled many adult users to try alternatives that are non-combustive, thus encouraging adoption.

Regulatory dynamics also play a significant role. In many regions, nicotine pouches fall under comparatively less restrictive frameworks than combustible or vaporized products, allowing for much wider distribution through retail and digital channels. This positioning, in turn, accelerates product availability and encourages investment by both established tobacco companies and new entrants. Flavor diversification, controlled-release formulations, and improvement in the pouch materials further enhance consumer appeal, driving repeat use and further market expansion.

E-commerce penetration further acts as a significant contributor, especially in markets where online nicotine purchasing is permissible. Digital platforms allow for targeted marketing, subscription models, and fast product launches that support higher engagement among adult users. The trends that will influence demand are ongoing urbanization, rising disposable incomes among emerging markets, and a growing cohort of adults looking for lifestyle-oriented nicotine formats. Category growth is strengthened by competitive pricing strategies and increased retail visibility.

Companies continue to invest in R&D to improve nicotine salts, stabilize moisture levels, and improve the sensory profile. This will help differentiate the products in a crowded marketplace. Combined, these factors provide a strong global demand trajectory for nicotine pouches.

Case Study on Cost Model of Nicotine Pouches Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale nicotine pouches manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed nicotine pouches manufacturing plant in India. This plant is designed to manufacture 20 million nicotine pouches annually.

Manufacturing Process: Nicotine pouch manufacturing is a controlled, sequenced process of formulation, blending, filling, sealing, and packaging to ensure consistent nicotine delivery, stability, and regulatory compliance. Production starts by preparing the base blend that typically consists of food-grade plant fibers, nicotine either synthetic or tobacco-derived, humectants, pH adjusters, stabilizers, and flavoring agents. Accurately metering these components into high-shear mixers introduces them where homogenization takes place to uniformly distribute moisture, maintain consistent particle sizes, and establish chemical stability. The resultant moist blend is then conditioned in such a way that it achieves a specifically defined humidity and temperature profile to optimize pouch fill characteristics and minimize clumping. Concomitantly to the preparation of this blend, the pouch material-always a permeable, medical-grade nonwoven fabric-is unwound and fed through an automated forming machine. The fabric is folded into small cavities that are ready to be filled with the nicotine mixture. Precision dosing systems ensure accurate amounts of the blend in each cavity for correct nicotine content in batches. Filled pouches are then ultrasonically or thermally sealed for integrity and to avoid leakage. Further, cutting systems separate the individual pouches into standard sizes. After the pouch is formed, the products are subjected to a process of conditioning in climate-controlled chambers, where moisture is stabilized, and flavors can mature. Quality control tests, which include nicotine concentration verification, microbial testing, weight uniformity, seal strength, and sensory evaluation, are carried out to ensure the manufacturing and regulatory specifications. Cleared batches are then moved for distribution on automated can-filling lines where pouches are counted and dispensed into cans, sealed, labeled, and packed. Maintaining strict hygiene, traceability, and documentation ensures product safety and consistency throughout the process.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

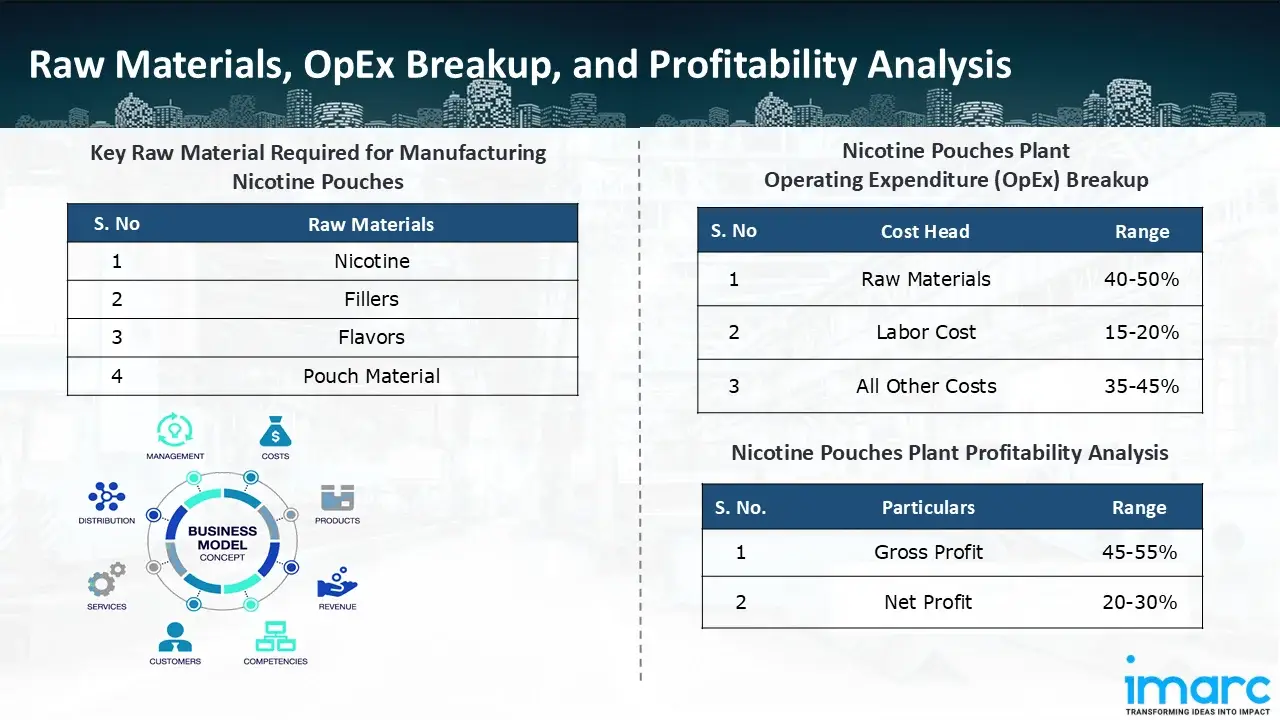

The basic raw materials required for nicotine pouches manufacturing include:

- Nicotine

- Fillers

- Flavors

- Pouch Material

Machine Section or Lines Required:

- Mixing

- Filling & Sealing

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in nicotine pouches manufacturing plant ranges between 40-50%, labor cost ranges between 15% to 20%, and all other costs ranges between 35-45% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 45-55%, and net profit lie between the range of 20-30% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the nicotine pouches manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 20 million nicotine pouches annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, Bangladesh authorised a Philip Morris project to manufacture nicotine pouches in the Meghna Industrial Economic Zone in Narayanganj. The plan requires an annual capacity of 536.3 million units, a US$ 5.82 million investment, and the start of production within a year.

- In January 2025, the U.S. Food and Drug Administration approved the premarket tobacco product application (PMTA) pathway for the commercialisation of 20 ZYN nicotine pouch products after a thorough scientific evaluation.

- In October 2024, British American Tobacco's U.S. subsidiary Reynolds American, announced that the business will introduce a synthetic nicotine version of its Velo nicotine pouches in the US.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104