The Fibre Framework: Cost Engineering Strategies for Medium Density Fibreboard Production

_11zon.webp)

What is Medium Density Fibreboard?

Medium Density Fibreboard (MDF) is an engineered wood product created by dissolving hardwood or softwood residues into wood fibers, blending them with wax and resin binders, and molding them into panels under the pressure of high temperature.

Key Applications Across Industries:

MDF is renowned for its even density, smooth surface, and easy machinability and is used extensively in cabinetry, flooring, furniture, and interior decoration because of its relative cheapness and adaptability as compared to plywood and solid wood.

What the Expert Says: Market Overview & Growth Drivers

The global medium density fibreboard market was reached USD 27.3 Billion in 2024. According to IMARC Group, the market is projected to reach USD 45.8 Billion by 2033, growing at a CAGR of 5.61% from 2025 to 2033. The global MDF market is led by accelerated expansion of the furniture and construction sectors, especially in developing nations.

Growing urbanization and disposable incomes have fueled demand for high-quality yet affordable furniture and interior design solutions. The cost-effectiveness, durability, and flexibility of MDF make it a favorite among manufacturers and consumers alike. Also driving MDF adoption is the world trend toward engineered and sustainable wood products due to deforestation issues and unstable solid wood supply. Increases in do-it-yourself residential remodeling projects, particularly in Europe and North America, and growing retail furniture markets in Asia-Pacific also complement market growth. Advances in resin technology and panel manufacturing have further improved MDF's moisture resistance and strength properties, propelling its application in various uses.

Case Study on Cost Model of Medium Density Fibreboard Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale medium density fibreboard manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed medium density fibreboard manufacturing plant in Alberta, Canada. This plant is designed to produce 300,000 cubic meter of medium density fibreboard per day.

Manufacturing Process: The production of Medium Density Fibreboard (MDF) is started by the gathering of wood wastes like sawdust, shavings, and chips from sawmills and other sources. They are cleaned, softened in a steam digester, and mechanically pulped into fibers in a refiner. The fibers are later dried in tube dryers and mixed with resins like urea-formaldehyde, wax, and additives using either a blowline or blender system. The resinated fibers are shaped into a mat in several layers and pre-pressed for thickness regulation and integrity of the mat. The mat is hot pressed under high temperature and pressure to cure the resin and create solid panels. The boards are cooled, sanded, trimmed, and cut to final size after pressing. Trimmed and sanded wood materials are commonly recycled into the process, whereas finished boards can be painted or laminated prior to packaging. In the process, particulate emissions, volatile organic compounds (VOCs), and hazardous air pollutants (HAPs) are produced, especially during pressing and drying operations.

_11zon.webp)

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials used in the medium density fibreboard manufacturing plant include wood chipping, urea-formaldehyde resin and paraffin wax. For a plant producing 1 meter of medium density fibreboard, 0.950 meter of wood chipping, 0.101 ton of urea-formaldehyde resin and 0.006 ton of paraffin wax.

List of Machinery:

The following equipment was required for the proposed plant:

- Belt Conveyor

- Teeth Roller Conveyor

- Metal Detector

- Drum Chipper

- Feedin Hopper

- Belt Conveyor

- Magnet Metal Remover

- Feedin Hopper

- Three Layer Swinging Screen

- Magnet Metal Remover

- Wood Chi Silo

- Magnet Metal Remover Belt

- Pre-heating Silo

- Anti-Blasting Device

- Feeding Screw

- Radiative Source of Positioner

- Wood Chip Steaming Tank

- Feeding Screw Conveyor

- Refiner

- Belt-Type Screw Conveyor

- 3-Way Valve

- Dryer Heat Exchanger

- Dryer Main Blower

- Dryer Main Pipe

- Dryer Main Cyclone Ø5800

- Dryer Main Valve

- Dryer Secondary Cyclones

- Grecon Spark Detector

- Fire-proof Conveyor

- Fiber Silo

- Storage Tanks

- Hardener Blending & Applying System

- Hardener Blending & Applying System

- Wax Melting & Applying System

- Mat Forming Machine

- Mat Pre-Heating System

- Inline Moisture Analyser

- Sweeping-back System

- Mat Weighing System

- Continuous Prepress

- Mat Trimming Saws

- Cross-cutting Saw

- Synchronous Conveyor

- Accelerating Conveyor I

- Waste Discharging Conveyor

- Accelerating Conveyor II

- Accelerating Conveyor III

- Swinging Shift Conveyor

- 2-Floor Storage Conveyor

- 2-Floor Storage Pre-Loader

- Loader

- Hot Press

- Unloader

- Hydraulic System

- Exhausting Fan

- Dry Board Conveyor

- Roll Conveyor I

- Roll Conveyor II

- Star Cooling Wheel

- Board Discharger I

- Board Discharger II

- Hydraulic Lift I

- Hydraulic Lift II

- Forklift Roll Conveyor I

- Forklift Roll Conveyor II

- Forklift Roll Conveyor

- Hydraulic Lift

- Board Push Feeding System

- Roll Conveyor

- Oriented Roll Conveyor

- Heavy Duty Sanding Machine

- Transition Conveyor

- Roll Conveyor

- Longitudinal Saw

- De-dusting System

- Discharging Conveyor

- Right-angle Roll Conveyor

- Transversal Saw

- Board Stacker

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

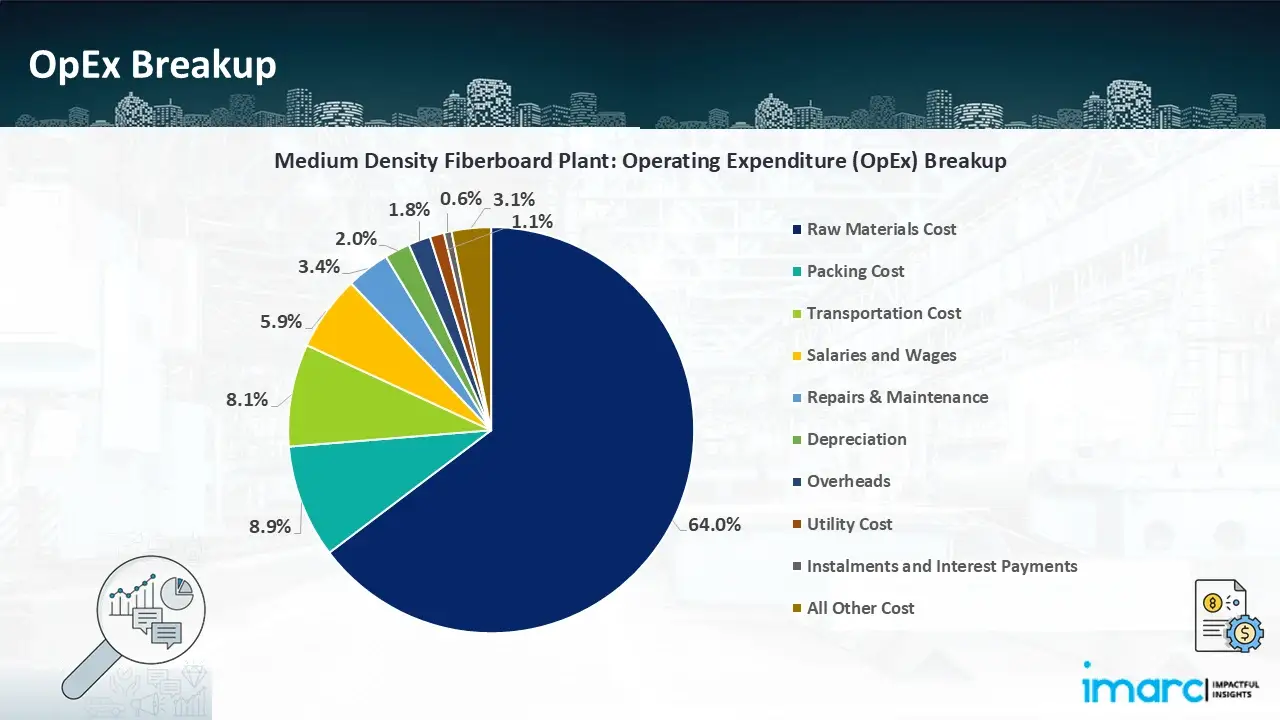

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

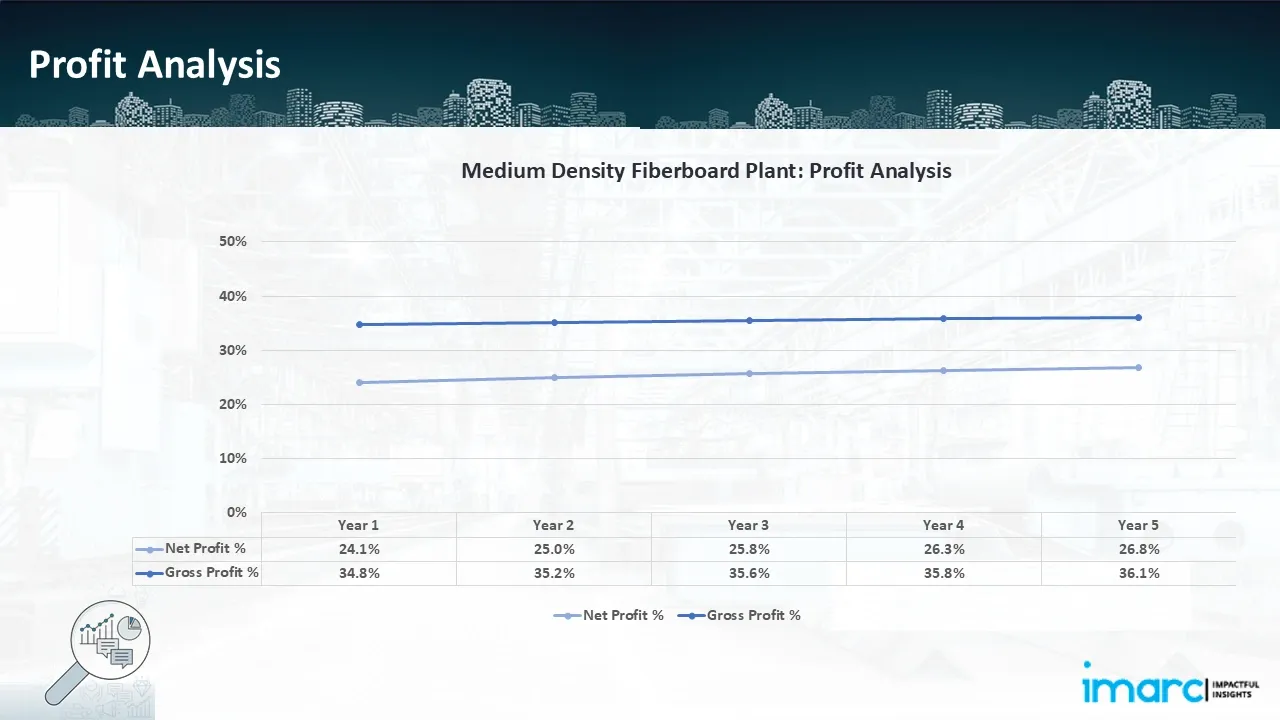

- Profitability Analysis Year on Year Basis: The proposed medium density fibreboard plant, with an annual capacity of approximately 300,000 cubic meters of medium density fibreboard, achieved an impressive revenue of US$ 123.9 Million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 34.8% to 36.1% by year 5, and net profit rises from 24.1% to 26.8%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the medium density fibreboard manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 300,000 cubic meter of medium density fibreboard annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights for strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In June 2025, with a substantial investment of Rs. 550 crore, Century Ply has started the first production of its particle boards line in Chennai, which has an annual capacity of 3,60,000 cubic meters (CBM). In Tamil Nadu, particle boards are continuously manufactured on 30 acres of land close to Chennai. The particle board division of Century Plyboards now has an annual capacity of 72,000 cubic meters. It is anticipated that the new factory will have an increased capacity of 2.4 lakh cubic meters annually.

- In May 2025, Homanit declared its intention to open its first manufacturing facility in the United States in Alcolu, South Carolina. Homanit, a German company, plans to invest $250 Million to construct the greenfield facility, which should be operational by 2028.

- In February 2025, Greenpanel Industries, opened a new MDF production line at its Srikalahasti facility in Tirupati, Andhra Pradesh. In order to satisfy the increasing demand, this expansion increased its yearly capacity from 660,000 CBM to 891,000 CBM and included a thin-MDF line (1.5–1.7 mm thick).

- In March 2024, Dieffenbacher has been contracted by Thai MDF manufacturer Wisewoods Co. Ltd. to provide a CEBRO MDF plant in order to increase production capacity at the company's headquarters located in Khao Yoi, Phetchaburi province.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104