Two-wheeler Clutch Plate Manufacturing Cost Analysis: Grip, Gear & Margins

What is Two-wheeler Clutch Plate?

A two-wheeler clutch plate is an essential transmission system part in motorcycles and scooters that helps to engage and disengage the engine power to the drivetrain. The clutch plate is a part of the clutch system, which usually consists of friction plates and steel plates, and is designed to transmit torque smoothly from the engine to the gearbox. The clutch plate works on the principle of friction, which enables smooth power transmission during the starting, gear shifting, and braking processes of the vehicle. Two-wheeler clutch plates are made of friction materials attached to metal substrates and are designed to resist high temperatures, friction, and repeated loading.

Key Applications Across Industries:

Two-wheeler clutch plates are mainly employed in motorcycles and geared scooters with varying engine capacities, from small commuter motorcycles to high-performance sports bikes. The primary purpose of two-wheeler clutch plates is to facilitate smooth engagement and disengagement of engine power, enabling the rider to start the vehicle without stalling and shift gears efficiently while riding. During acceleration and braking, clutch plates assist in regulating torque transmission, preventing abrupt jerks and protecting the transmission system.

In urban commuting motorcycles, clutch plates are made to be long-lasting and smooth-acting, even when subjected to frequent stop-and-go traffic. Such applications require clutch plates to exhibit consistent friction, resistance to glazing, and low wear even when used repeatedly. In performance and sports motorcycles, clutch plates are required to support higher torque and higher temperatures, which call for the use of highly advanced friction materials that exhibit high grip force without sacrificing smoothness.

Another area where clutch plates are in high demand is in the aftermarket replacement and maintenance market. Because of normal wear and tear over time, clutch plates are considered consumable items, thus ensuring a steady stream of demand in the service and spare parts market. They are replaced during routine servicing, performance upgrades, or when the motorcyclist complains of slippage and loss of power transmission.

Two-wheeler clutch plates are also used in motorsports and off-road motorcycles, where they are exposed to extreme operating conditions such as high temperatures, dust, and sudden changes in loading. In such applications, the need for higher material strength and heat resistance is paramount. In general, clutch plates are a crucial component in ensuring ride quality, vehicle reliability, and drivetrain durability.

What the Expert Says: Market Overview & Growth Drivers

The global automotive clutch market reached a value of USD 13.7 Billion in 2024. According to IMARC Group, the market is projected to reach USD 20.2 Billion by 2033, at a projected CAGR of 4.4% during 2025-2033.

The two-wheeler clutch plate market is driven by the popularity of motorcycles and scooters as an economical and efficient means of transportation. In developing countries, two-wheelers are the primary means of personal transportation due to their low cost of ownership, fuel efficiency, and ease of mobility in congested roads. This directly contributes to the demand for clutch plates in the replacement market.

The rising number of vehicles on the road and the average age of vehicles are major factors in the replacement market. Clutch plates are wear-out components that need to be replaced periodically, thus ensuring a constant demand for the component throughout the vehicle’s life. Organized service networks and awareness about preventive maintenance also contribute to the demand for replacement.

Urbanization and traffic congestion are also factors that affect the wear and tear of clutch plates, as constant gear shifting and stop-and-go traffic patterns tend to wear out the friction material faster. This results in a higher replacement rate, especially in urban areas with high population density. Moreover, the rising trend of delivery services using motorcycles and shared mobility vehicles increases vehicle usage, thereby increasing wear and tear and driving the demand for robust clutch plates.

Technological advancements in the field of friction materials and production techniques also aid in the growth of the market. Improved heat resistance, smoother engagement, and longer lifespan make the latest clutch plates more desirable for both producers and consumers. Government focus on vehicle efficiency and emissions indirectly promotes improved clutch system design, as smoother power transmission enhances overall drivetrain efficiency.

Lastly, the trend of high-performance motorcycles and motorsports has also driven the demand for high-performance clutch plates in a niche market. Along with the rising trend of two-wheeler sales and regular replacement cycles, all these factors together have driven the demand for two-wheeler clutch plate manufacturing.

Case Study on Cost Model of Two-wheeler Clutch Plate Manufacturing Plant

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale two-wheeler clutch plate manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed two-wheeler clutch plate manufacturing plant in India. This plant is designed to manufacture 2 million sets of two-wheeler clutch plate annually.

Manufacturing Process: The production process of two-wheeler clutch plates is a precision-based process that aims to ensure consistent friction properties, durability, and heat resistance. The process starts with raw material selection, where steel sheets are selected for the core plate and friction materials are developed by mixing fibers, resins, fillers, and friction modifiers. These friction compounds are developed to ensure stable torque transmission with minimal wear and heat resistance.

The subsequent step involves the steel core plates being punched and machined to the desired size, including inner and outer teeth to enable engagement with the clutch hub and basket. The punched plates then receive surface treatments like cleaning, roughening, or phosphating to enhance friction material bonding. Simultaneously, friction linings are developed using mixing, calendaring, or molding techniques to ensure equal thickness and density.

The bonding process ensues, wherein the friction material is bonded to both sides of the steel core using heat-resistant adhesives or direct molding under heat and pressure. This is necessary for ensuring good adhesion and thickness control. After bonding, the clutch plates are cured and heat-treated to improve material properties and heat resistance.

Next, the plates are ground and finished to ensure accurate flatness, thickness tolerance, and surface finish. This is essential for smooth engagement of the clutch. The finished plates are then tested for quality, involving checks for dimensions, friction coefficient, torque capacity, and heat resistance.

Lastly, the approved clutch plates are cleaned, packaged, and shipped to original equipment manufacturers or the aftermarket. Contemporary manufacturing practices focus on automation, traceability, and quality control to ensure consistent performance under varying operating conditions.

Explore in-depth findings for this market, Request Sample

Raw Material Required:

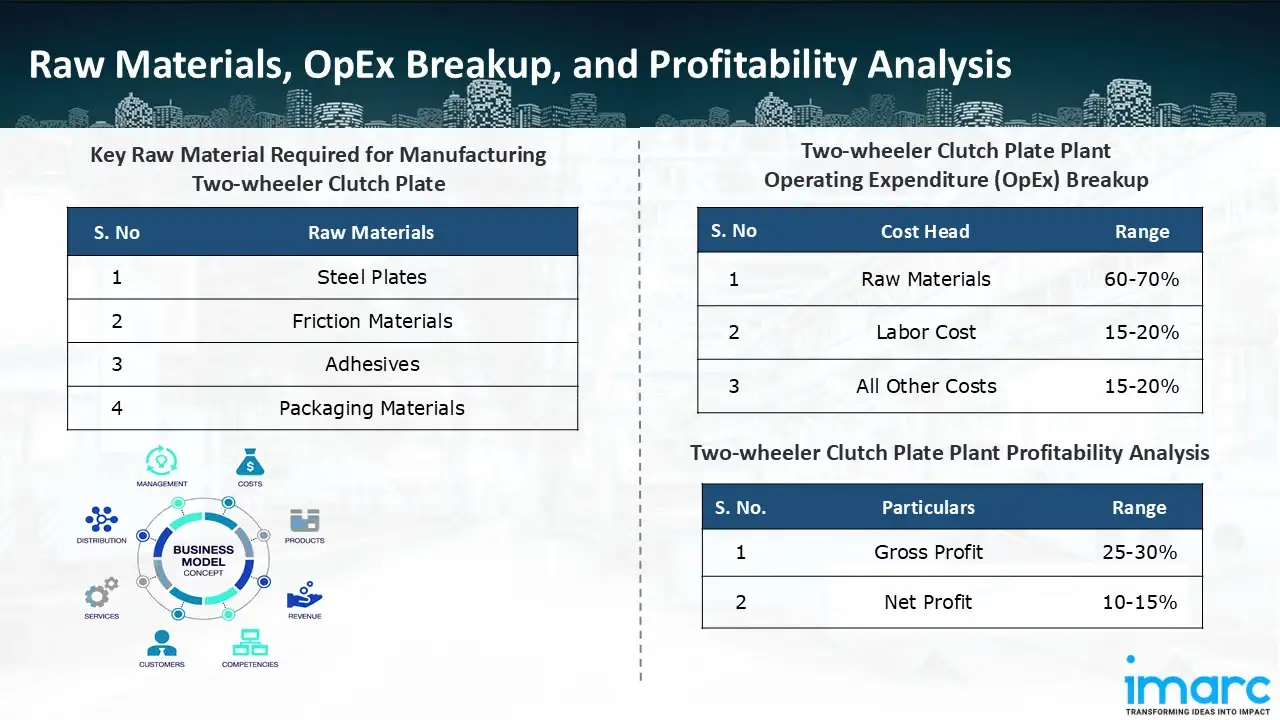

The basic raw materials required for two-wheeler clutch plate manufacturing include:

- Steel Plates

- Friction Materials

- Adhesives

- Packaging Materials

Machine Section or Lines Required:

- Stamping

- Bonding

- Riveting

- Grinding

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in two-wheeler clutch plate manufacturing plant ranges between 60-70%, labor cost ranges between 15% to 20%, and all other costs ranges between 15-20% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-30%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the two-wheeler clutch plate manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 2 million sets of two-wheeler clutch plate annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In January 2026: Schaeffler India Limited, a player in the clutch industry, announced that it would be attending SIAT 2026 and showcasing a variety of automotive technology intended for India's developing car market.

- In February 2025, Schaeffler India announced strengthening its presence in the two- and three-wheeler segments, leveraging its existing capabilities in internal combustion engine (ICE) components and its recent expansion into electric powertrain solutions through the Vitesco Technologies acquisition.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104