Building Structures by Ceramic Tiles: A Comprehensive Cost Model

_11zon.webp)

What is Ceramic tiles?

Ceramic tiles are durable, versatile, and cost-effective building materials made from natural clay, sand, and water, which are shaped, glazed, and kiln-fired at high temperatures.

Key Applications Across Industries:

Known for their aesthetic appeal, resistance to moisture, and ease of maintenance, ceramic tiles are widely used in flooring, walls, kitchen backsplashes, and bathrooms across residential, commercial, and industrial spaces. They are available in different types like glazed, unglazed, porcelain, and vitrified tiles, with different design and performance choices. Ceramic tiles have become a primary component of contemporary construction and interior design in India due to spurring urbanization, increasing disposable incomes, and expanding demand for visually appealing yet practical surfaces. The market has both large-scale manufacturers as well as regional manufacturers, supplying domestic and export orders.

What the Expert Says: Market Overview & Growth Drivers

The global ceramic tiles market reached USD 89.2 Billion in 2024. According to IMARC Group, the market is projected to reach USD 138.4 Billion by 2033, exhibiting a CAGR of 5% during 2025-2033. The global ceramic tiles industry is influenced by some of the most important factors combined, which together propel its development across residential, commercial, and industrial sectors. Accelerating urbanization and growing construction activity, particularly in emerging markets such as India, China, Brazil, and Southeast Asia, are among the primary drivers.

With increasing population migrating to cities, there is a growing requirement for new housing, commercial spaces, and public infrastructure, and this increases the demand for ceramic tiles because of their cost-effectiveness, durability, and design variety. Increasing disposable income and shifting consumer preference towards nicely decorated interiors are also contributing to higher use of good quality and decorative ceramic tiles. Moreover, advances in digital printing and tile production technology have improved design flexibility and manufacturing efficiency, making the ceramic tile more desirable to a wider range of customers. Increased environmental awareness is compelling the demand for green tiles, and producers are increasingly inclined towards sustainable production techniques. Also, renovation and remodeling activity, especially among developed countries, continues to fuel market demand. Hotels and retail businesses are also spending big on interior upgrades, where ceramic tiles find great favor. Finally, government policies encouraging infrastructure development and low-cost housing projects also contribute to long-term growth of the global ceramic tiles market.

Case Study on Cost Model of Ceramic tiles Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale ceramic tiles manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed ceramic tiles manufacturing plant in United Kingdom. This plant is designed to produce 7,000 square meters of ceramic tiles per day.

Manufacturing Process: The production of ceramic tiles in the United Kingdom is a multi-step process that commences with the initial crushing of raw materials like ball clay, feldspar, silica sand, and dolomite. These are precisely weighed through automated quality control systems prior to being combined with multiple mixers to achieve uniformity. Water is added in wet milling in ball mills to form a slurry, which is dried by filter pressing and spray drying to produce 35–40% moisture content granules. The granules are maintained for homogeneity and then molded in high-pressure presses. The form tiles are dried to below 1% moisture content, glazed with base coats and decoration layers in frit-based materials. The tiles are then fired in high-temperature speed-rolling kilns, mainly gas-fired, which induces hardness, strength, and resistance. Firing is followed by the removal of defective tiles and packing of the finished products in cardboard boxes for distribution. This energy-hungry process, particularly during firing, is mainly based on natural gas with coal or biomass alternatives wherever necessary.

_11zon.webp)

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials used in ceramic tiles manufacturing plant include potassium feldspar, silica sand, bail clay, sodium feldspar, dolomite, STTP and sodium silicate Indsperse FC 2050, and frit. For a plant manufacturing 1 square metre of ceramic tiles weighing 15 kg, 5.85 kg of potassium feldspar, 3.75 kg of silica sand, 4.50 kg of bail clay, 0.30 kg of sodium feldspar, 0.45 kg of dolomite, 0.15 kg of STTP and sodium silicate Indsperse FC 2050, and 0.30 kg frit is required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

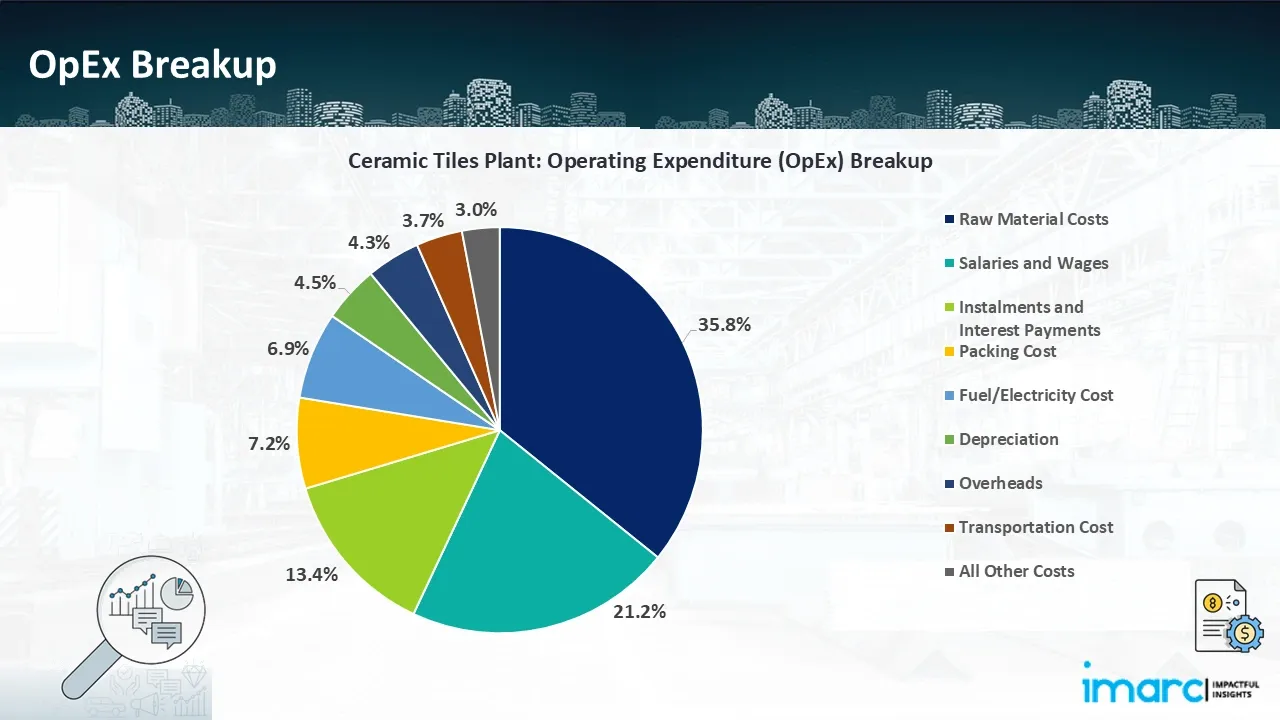

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

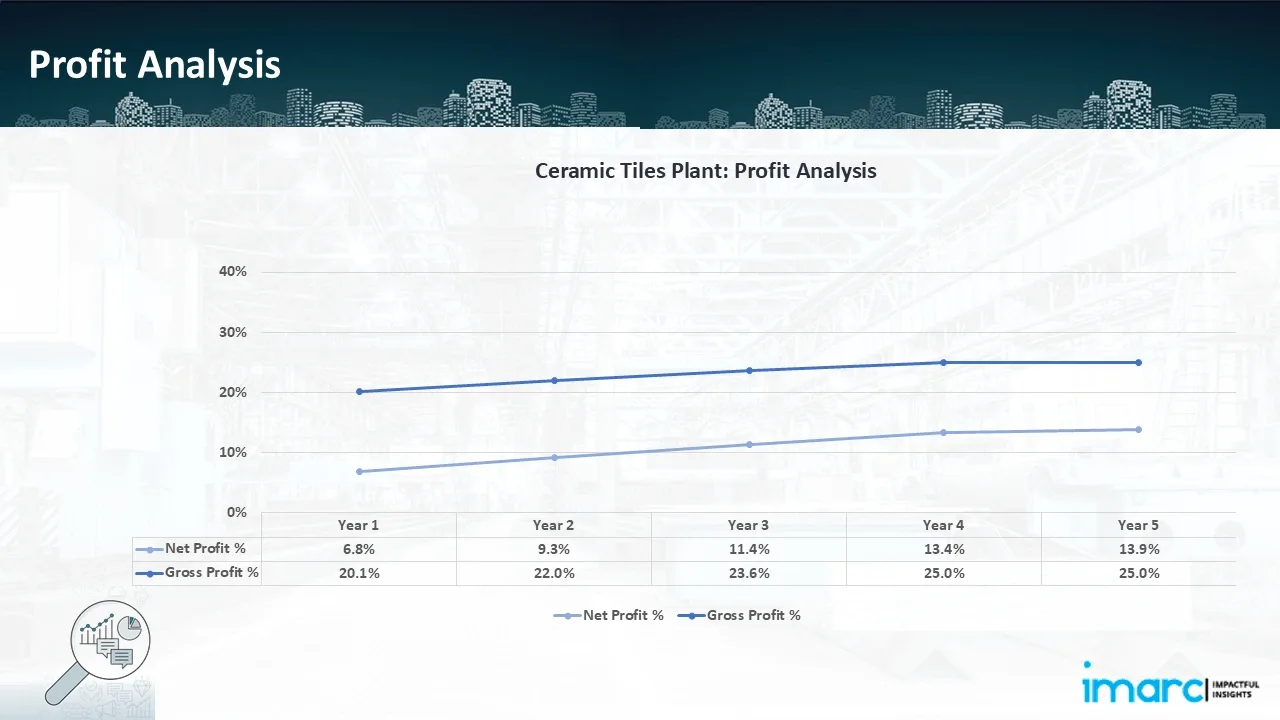

- Profitability Analysis Year on Year Basis: The proposed ceramic tiles plant, with a capacity of approximately 7,000 square meters of ceramic tiles per day, achieved an impressive revenue of US$ 26.0 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 20.1% to 25.0% by year 5, and net profit rises from 6.8% to 13.9%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the ceramic tiles manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 7,000 square meters of ceramic tiles per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2025, Elios Ceramica, a division of the Italcer Group, owns the Fiorano Modenese facility, for which LB Technology just finished a significant supply project. A new line for accepting spray-dried material from trucks, a set of high-capacity silos, and a press feeding transfer system that can be completely integrated with the current equipment were all installed as part of the project to upgrade the current system.

- In March 2025, Asian Granito India Ltd. (AGL) expanded its regional market presence and customer interaction by opening a 3,500-square-foot luxury tile exhibition centre in Hyderabad.

- In July 2024, the Premium Experience Gallery at Ahmedabad Airport was opened by Asian Granito India Limited (AGL), a top manufacturer of premium surface products like tiles, marbles, quartz, and bathware solutions. This creative marketing campaign, which is ideally situated in the arrivals area, raises the bar for the sector.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104