Liquid Detergent Manufacturing Cost Analysis: Crystal Clear Costs

What is Liquid Detergent?

Liquid detergent is a formulated cleaning solution comprising surfactants, solvents, builders, enzymes, pH stabilizers, perfumes, and other additives, which are collectively used for removing dirt, stains, and oils from fabrics, dishes, and different surfaces. Unlike powdered detergents, liquid detergents dissolve immediately in water, allowing even distribution during washing and effective performance in both hot and cold water. Their fluid consistency makes dosing easier, compatibility with modern washing machines easier, and incorporation of specialized ingredients such as stain-specific enzymes or fabric conditioners easier. Liquid detergents show superior penetration into fibers, reduced residue formation, and enhanced convenience; therefore, they have become a preferred cleaning product across households and industries.

Key Applications Across Industries:

Liquid detergent finds broad applications in household, commercial, institutional, and industrial cleaning because of their versatility and efficiency. Applications in households include laundry care, wherein liquid detergents effectively take away stains from cotton, synthetics, wool, and blended fabrics. Because they quickly dissolve in water, they are perfect for front-load and top-load washing machines, particularly with cold washes wherein powdered detergents cannot dissolve into the water. Many formulations employ enzymes acting upon specific stains, including proteins, oils, or starches, in addition to brighteners and fragrances to enhance the appearance and freshness of fabrics.

In dishwashing, liquid detergents are applied in manual dishwashing and also in dishwasher-compatible formulations that break grease, food residues, and tough deposits. They are gentler on hands and surfaces compared to abrasive powders. Commercially, liquid detergents are important in hotels, hospitals, laundromats, restaurants, and cleaning-service firms, where bulk washing necessitates consistent cleaning and ease of dosing. Industrial uses involve textile processing, automobile cleaning, and surface preparation; high-foaming or low-foaming specialized formulations depend on the specific process requirements.

Liquid detergents with disinfectant properties are being used in institutional settings for hygienic cleaning in healthcare facilities, schools, and public places. Specialty variants, including baby-safe detergents, hypoallergenic formulas, and eco-friendly plant-based detergents, further extend their use to sensitive and sustainability-conscious consumer groups.

What the Expert Says: Market Overview & Growth Drivers

The global liquid detergent market reached a value of USD 35.12 Billion in 2024. According to IMARC Group, the market is projected to reach USD 54.84 Billion by 2033, at a projected CAGR of 5.01% during 2025-2033. The global liquid detergent market is expected to record robust growth supported by evolving consumer lifestyles, rising urbanization, improving washing machine penetration, and increasing demand for convenience-oriented cleaning products. The primary drivers in the market address the shift from the traditional powder detergent to the liquid format on account of better solubility, accuracy in dosing, and compatibility with high efficiency washing machines. In turn, as households begin to adopt automated laundry appliances, preference naturally shifts to liquid detergents that generate controlled foam, protect machine parts, and ensure better cleaning performance in short-cycle and low-temperature washing.

Another key growth driver is the increasing importance being attached to fabric care and special cleaning solutions. The consumer demand for detergents that are focused on delicate fabrics, sportswear, baby clothes, and high-end garments has encouraged manufacturers to launch more enzyme-rich, pH-balanced, and gentle formulas. The trend toward bio-based detergents and environmentally friendly cleaning products, which is influenced by environmental awareness and sustainability targets, also transforms the market. Liquid formats are ideal carriers for plant-derived surfactants and biodegradable ingredients, making them central to green cleaning initiatives.

The growing commercial and institutional sectors, in particular, hospitality, health care, and food service, greatly increase the demand for large-volume and professional-grade liquid detergents. Performance, hygiene compliance, and ease of storage and dilution are key considerations for these users-advantages that liquid detergents can readily deliver. Rapid population growth, higher disposable incomes, and improved retail infrastructure in emerging markets also help. E-commerce platforms accelerate this adoption further through subscription models, bulk discounts, and doorstep delivery. All put together, technological advancements, sustainability trends, premiumization, and expanding cleaning requirements are the core factors driving the acceleration in the growth of the global liquid detergent market.

Case Study on Cost Model of Liquid Detergent Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale liquid detergent manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed liquid detergent manufacturing plant in India. This plant is designed to manufacture 5,000 kilo liters of liquid detergents annually.

Manufacturing Process: Liquid detergent manufacturing consists of mixing, heating, blending, and quality testing in various combinations under controlled conditions to achieve a stable and efficient cleaning formulation. The production process starts with the preparation of the surfactant base, which can contain anionic, nonionic, cationic, or amphoteric surfactants. These are mixed in a mixing tank containing water, ensuring thorough stirring to achieve a uniform solution. Builders are added next to the formulation to increase cleaning efficiency or water softening, such as sodium citrate or sodium carbonate.

Once the base mixture is uniform, other additives such as enzymes, preservatives, thickeners, optical brighteners, pH adjusters, and foam regulators are added. In general, enzymes must be added at lower temperatures to maintain activity. Also, solvents in the form of ethanol or propylene glycol are added to enhance stability and solubility. It is continuously agitated for uniform mixing while heating could also be applied to improve the dissolution of solid components and for proper viscosity. Fragrances and dyes are carefully added after the main formulation is complete to avoid any chemical reaction affecting the performance of the detergent. The product then passes through filters to remove impurities or undissolved particles. Quality control tests confirm viscosity, pH, cleaning performance, foam characteristics, stability, and microbial safety. If the formulation meets specifications, the next step is the filling and packaging stage, in which automated systems fill bottles, pouches, or bulk containers. Packaging might include child-safe caps, measuring lids, or refillable designs. Finally, the finished detergent is labeled and batch-coded, then palletized for distribution to retail, industrial, or institutional buyers.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

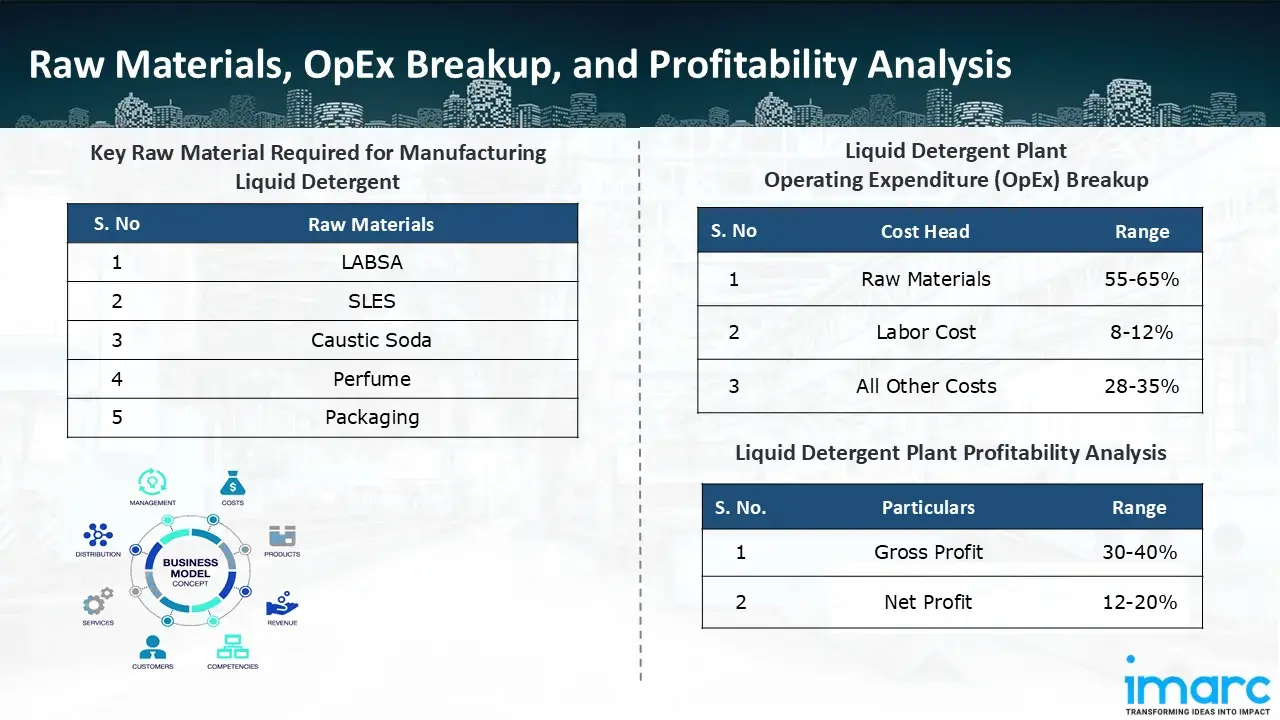

The basic raw materials required for liquid detergent manufacturing include:

- LABSA

- SLES

- Caustic Soda

- Perfume

- Packaging

Machine Section or Lines Required:

- Reactor Vessels

- Mixing Tanks

- Filling Line

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in liquid detergent manufacturing plant ranges between 55-65%, labor cost ranges between 8% to 12%, and all other costs ranges between 28-35% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 12-20% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the liquid detergent manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 5,000 kilo liters of liquid detergent annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In September 2025, Tide announced updating to its Original Liquid Detergent to an enhanced recipe that delivers the most tech-advanced stain removal ever and, maintains your brights brighter, whiter, and provides longer-lasting freshness of the trademark Tide aroma.

- In April 2025, Henkel, announced introducing concentrated formulae and packaging across all, Persil and Snuggle liquid laundry detergents. This upgrade delivers laundry-doers effective detergent cleansing power and fabric conditioning softness and smell at a more concentrated level per load.

- In April 2024, Tide unveiled Tide evo, a new laundry detergent for tiles. Tens of thousands of tiny fibres are used to create layers of soap without the need for extra liquid or fillers thanks to years of intensive research and development.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104