Ready Mix Concrete Manufacturing Cost Analysis: From Batch to Build

What is Ready Mix Concrete?

Ready mix concrete (RMC) is a precisely engineered construction material produced in a controlled environment within a batching plant and delivered to construction sites in a freshly mixed, plastic state. It is formulated by combining cement, aggregates, water, and chemical or mineral admixtures in carefully proportioned quantities to achieve specific performance characteristics. Unlike site-mixed concrete, RMC ensures consistent quality, uniformity, and superior workability through automated production and quality control processes. The concrete is transported using transit mixers or agitator trucks, maintaining its workability until it reaches the point of placement. By eliminating on-site mixing, RMC minimizes labor requirements, reduces material wastage, and improves construction efficiency and structural reliability.

Key Applications Across Industries:

Ready mix concrete is used extensively across residential, commercial, industrial, and infrastructure projects, valued for its quality, efficiency, and versatility.

In residential construction, RMC is commonly used for foundations, slabs, beams, columns, driveways, and flooring. Its consistent quality ensures structural strength and long-term durability while significantly reducing construction time. For both low-rise and high-rise housing developments, RMC provides a dependable and time-saving solution.

In commercial and industrial projects, such as office buildings, shopping complexes, warehouses, factories, and data centers, RMC is preferred for its ability to meet specific engineering and performance requirements. Centralized batching plants can produce specialized concrete grades such as high-strength or fast-setting concrete, tailored for heavy loads, architectural precision, and large-volume pours.

In infrastructure development, ready mix concrete plays a pivotal role in constructing roads, highways, bridges, flyovers, tunnels, airports, and ports. Its ability to be produced in large quantities with consistent quality makes it ideal for long-span and high-durability projects. Urban infrastructure applications include drainage systems, pavements, retaining walls, and utility structures, where uniformity and speed are critical.

Additionally, RMC is widely used in precast concrete elements, mass concrete applications, and specialized formulations such as waterproof, self-compacting, and high-strength concretes. Its adaptability to a wide range of technical and structural requirements has established RMC as an essential material in modern construction.

What the Expert Says: Market Overview & Growth Drivers

The global ready mix concrete market reached a value of USD 998.69 Billion in 2024. According to IMARC Group, the market is projected to reach USD 2,106.50 Billion by 2033, at a projected CAGR of 8.6% during 2025-2033. The global ready mix concrete market continues to expand, driven by urbanization, infrastructure investment, and growing demand for efficient, high-quality construction materials.

Rapid urban growth and increasing population levels are fueling continuous demand for residential housing, commercial complexes, and public infrastructure, all of which depend on reliable concrete supply. RMC is increasingly preferred over site-mixed alternatives because it delivers better quality control, reduced material waste, and faster project completion. Infrastructure development is a key growth catalyst. Governments and private investors worldwide are channeling resources into roads, bridges, public transport, water systems, and utilities. Large-scale projects require concrete that meets strict performance and durability standards, which batching plants can consistently achieve through automated, quality-assured production.

Labor shortages and the push for construction efficiency further support the adoption of RMC. By centralizing production and eliminating on-site mixing, RMC reduces the need for skilled labor and simplifies logistics, improving site safety and minimizing environmental impact. Technological progress also plays a significant role. Advances in chemical admixtures, automation, and digital quality monitoring have led to the production of innovative concrete types such as self-compacting, low-permeability, and high-performance mixes, that meet evolving structural, and sustainability demands.

Environmental sustainability is another major driver. Centralized batching allows precise control over raw material use, water consumption, and emissions, while the incorporation of supplementary cementitious materials (like fly ash or slag) supports carbon reduction goals. Together, these factors including urban expansion, infrastructure growth, labor efficiency, technological innovation, and sustainability initiatives are driving sustained global demand and continuous evolution in ready mix concrete manufacturing.

Case Study on Cost Model of Ready Mix Concrete Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale ready mix concrete manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed ready mix concrete manufacturing plant in India. This plant is designed to manufacture 200,000 cubic meters of ready-mix concrete annually.

Manufacturing Process: The manufacturing of ready-mix concrete (RMC) involves a sequence of controlled material handling, precise batching, and systematic mixing operations carried out in a centralized batching plant. This controlled production environment ensures uniform quality, high efficiency, and compliance with stringent construction standards. The process begins with the selection and storage of raw materials like cement, fine aggregates (sand), coarse aggregates, water, and chemical or mineral admixtures. Each material undergoes testing and approval to ensure it meets required quality specifications. Aggregates are stored in separate bins to prevent cross-contamination, while cement is kept in sealed silos to protect it from moisture and maintain consistency.

The next critical step is batching, where raw materials are measured according to a predefined mix design that specifies the desired concrete strength, durability, and workability. Modern RMC plants use fully automated batching systems with computerized controls to ensure precise weighing and consistent proportions for every batch. Once the materials are accurately batched, they are transferred to a mixer, which may be a central stationary mixer or directly integrated into a transit mixer truck. Mixing is carried out for a controlled duration to achieve a homogeneous blend of cement paste, aggregates, and water, ensuring uniform quality throughout the batch.

After mixing, the fresh concrete is loaded into transit mixers for delivery to the construction site. The rotating drum of the mixer keeps the concrete in motion during transport, preventing segregation and premature setting. Depending on travel distance and site conditions, admixtures such as retarders or superplasticizers may be added to maintain workability and ease of placement upon arrival. At the construction site, the ready-mix concrete is discharged directly into formwork, concrete pumps, or buckets for placement. The material’s fresh properties are verified through slump tests, temperature checks, and compressive strength sampling to ensure compliance with design requirements.

Throughout the process, quality control is maintained at every stage from raw material inspection to final delivery. This centralized production approach minimizes material wastage, optimizes resource use, and guarantees consistent, high-quality concrete delivered on time to meet the demands of modern construction projects.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

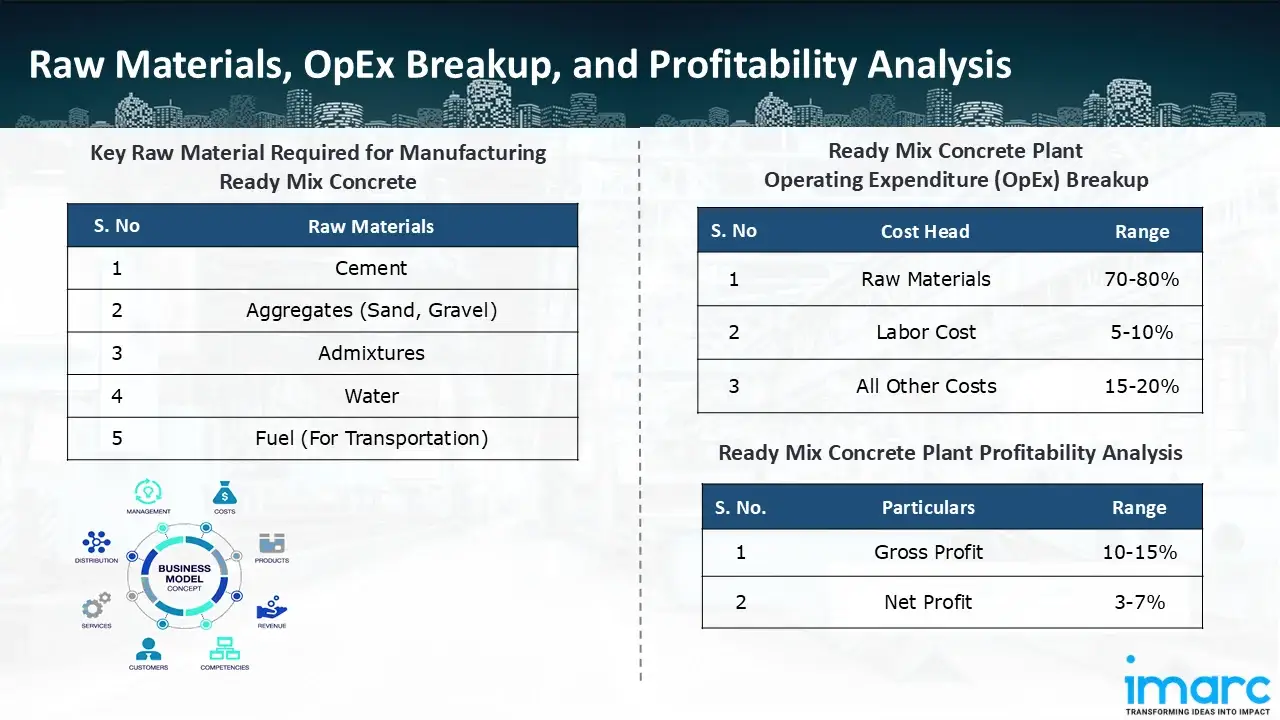

The basic raw materials required for ready mix concrete manufacturing include:

- Cement

- Aggregates (Sand, Gravel)

- Admixtures

- Water

- Fuel (For Transportation)

Machine Section or Lines Required:

- Batching Plant

- Mixing Unit

- Laboratory

- Transportation Fleet (Transit Mixers

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in ready mix concrete manufacturing plant ranges between 70-80%, labor cost ranges between 5% to 10%, and all other costs ranges between 15-20% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 10-15%, and net profit lie between the range of 3-7% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the ready-mix concrete manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 200,000 cubic meters of ready-mix concrete annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In April 2024, CRH announced that it has acquired Northgate Ready Mix, LLC and BoDean Company Inc. in Santa Rosa, California. These purchases strengthen CRH's capacity to offer integrated solutions to clients in the lucrative Northern California market and mark the company's first foray into the state of California through its Materials Solutions division.

- In February 2024, Nuvoco Vistas Corp. Ltd., the fifth-largest cement company in India, expanded its operational footprint with the opening of its second cutting-edge Ready-mix Concrete Plant (RMX), known as Patna-II.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104