Feasibility Study for Ethyl Acetate Production: A Cost Model Approach

_11zon.webp)

What is Ethyl Acetate?

Ethyl acetate is a volatile, colorless, flammable liquid having a characteristic sweet smell. It is primarily used as a solvent in various industrial and commercial applications. It finds primary production through esterification from ethanol and acetic acid.

Key Applications Across Industries:

It possesses excellent solvent properties, a rapid evaporation rate, and low toxicity, which makes it very useful in the paints and coatings industry, adhesives, printing inks, pharmaceuticals, and food and beverage industries (as a flavoring agent). Ethyl acetate also finds application in the decaffeination of tea and coffee. Its environmental friendliness, as opposed to other volatile organic compounds (VOCs), further adds to its popularity in contemporary sustainable manufacturing settings. With the increasing global demand across various industries, it continues to be a primary chemical in the solvents industry.

What the Expert Says: Market Overview & Growth Drivers

The global ethyl acetate market was reached USD 6.2 Billion in 2024. According to IMARC Group, the market is projected to reach USD 10.9 Billion by 2033, at a projected CAGR of 6.18% during 2025-2033. The global market for ethyl acetate is fueled by robust demand across various end-use industries.

One of the key drivers of growth is the growing paints and coatings industry, particularly in fast-growing emerging economies that are undergoing increased urbanization and industrialization. Ethyl acetate's solvent power makes it a critical component in paints, varnishes, and coatings formulations. The printing industry is another large user, in which ethyl acetate is preferred due to its fast evaporation characteristics in inks applied to flexible packaging. Further, the pharmaceutical industry employs it in the formulation and extraction of drugs, and the food and beverage industry employ it as a flavor additive. Increased demand for low-VOC and environmentally friendly solvents has also spurred manufacturers to make the transition to ethyl acetate, as its relatively lower environmental footprint makes it attractive. Additionally, increased production of bio-based ethyl acetate from renewable feedstocks is also fueling market growth as environmental regulations tighten. Growing automotive and construction industries, rising investment in green chemistry, and the increasing trend towards sustainable packaging and printing are expected to continue driving demand for ethyl acetate worldwide.

Case Study on Cost Model of Ethyl Acetate Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale ethyl acetate manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed ethyl acetate manufacturing plant in India. This plant is designed to produce 200 tons of ethyl acetate per day.

Manufacturing Process: The process of producing ethyl acetate constitutes several stages of reaction, distillation, separation, and recycling to provide high purity and optimal use of resources. Acetic acid and ethanol are first preheated with a catalyst, i.e., sulfuric acid, in a feedstock pre-heater to start the esterification process. The feedstock is then fed into the azeotropy column, where an azeotropic distillation splits ethyl acetate from water. The product is then reheated and sent through the azeotropy column condenser and reflux pump to improve separation. Within the azeotropy column phase separator, the mixture separates into three streams: one to the finished product phase separator, one to the recycle to the feedstock pre-heater, and the last to the finished product column. The product column and its condensers, reflux towers, and separators further clean the product. Light impurities and lighter components are eliminated through cooling and phase separation. The recovery column further cleans the product, and part of it is recycled for energy efficiency. The rest of the by-products is redirected to the effluent tank and treatment plant for proper disposal. The last purified ethyl acetate is kept in product tanks, and by-products and waste are well-controlled to be environmentally friendly. This closed system increases the quality of the product with reduced waste and operational expenses.

_11zon.webp)

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials used in the ethyl acetate manufacturing plant include acetic acid, ethanol and sulfuric acid. For a plant producing 1 ton of ethyl acetate, the required quantities are as follows: 0.676 tons of acetic acid, 0.531 tons of ethanol and 0.0001 ton of sulfuric acid.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

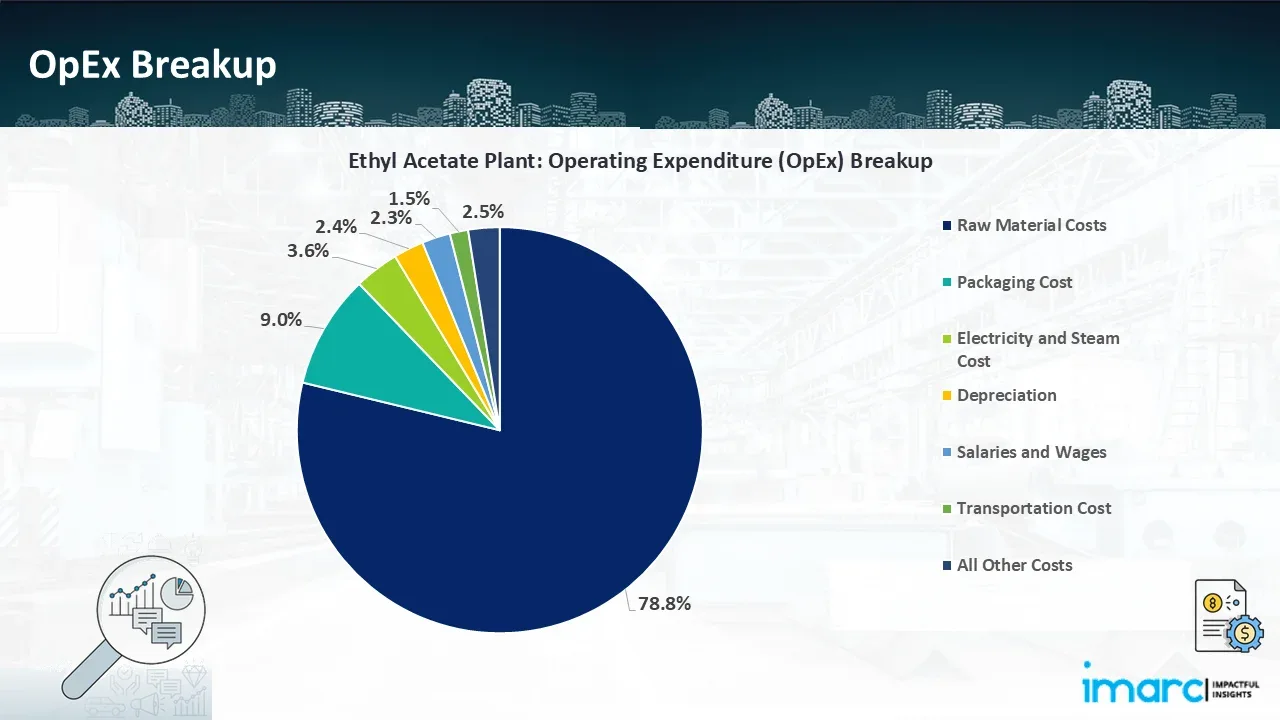

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

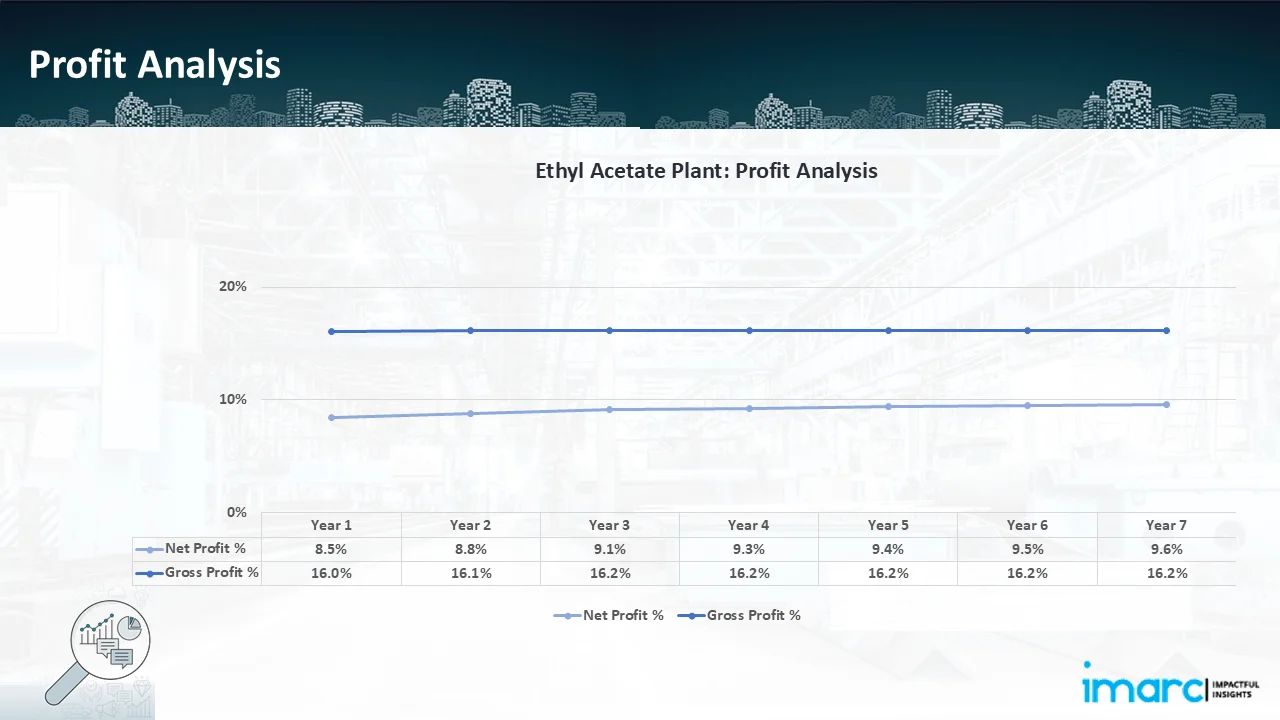

- Profitability Analysis Year on Year Basis: The proposed ethyl acetate plant, with a capacity of 200 tons of ethyl acetate per day, achieved an impressive revenue of INR 2,311.1 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 16.0% to 16.2% by year 7, and net profit rises from 8.5% to 9.6%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the ethyl acetate manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 200 tons of ethyl acetate per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In November 2024, a memorandum of agreement was signed in November 2024 between INEOS Acetyls and Gujarat Narmada Valley Fertilisers & Chemicals Ltd (GNFC) to investigate the possibility of building a 600 KTA acetic acid facility in Bharuch, Gujarat. Since acetic acid is an essential precursor to ethyl acetate, it supports the possibility of downstream production in the future.

- In November 2024, Viridis Chemical plans to move its renewable ethyl acetate production plant from Nebraska to Peoria, Illinois, by the end of 2025. It is anticipated that the move will strengthen the company's position in sustainable solvents and improve logistics and operational resilience.

- In October 2024, a capital investment of INR 181.9 crore has been granted by Laxmi Organic Industries Limited, the leading company in India's acetyl and ketene and diketene intermediaries, to establish n-Butyl Acetate and Ethyl Acetate plants in Dahej, Gujarat, and Lote, Maharashtra, respectively.

- In December 2022, facility for producing renewable ethyl acetate from sustainable ethanol will be constructed by CropEnergies AG, Mannheim, Germany. The Zeitz Chemical and Industrial Park in Elsteraue, Germany, is the anticipated site. The new production facility will require a total investment of 120–130 million euros, which will be covered by the current cash position. At the moment, CropEnergies works in construction and detailed engineering. Early in 2024 is when construction is expected to begin, and the latest date for commissioning is the summer of 2025.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104