Mattress Manufacturing Cost Analysis: From Foam to Fortune

What is Mattress?

A mattress is a cushioned structure intended to support the human body, either while sleeping, resting, or for therapeutic purposes. It is typically made up of comfort layers, including foam, latex, fiber, or gel, combined with a supportive core, like innerspring coils, high-density foam, or hybrid constructions. Mattresses are designed to evenly distribute body weight to relieve pressure points and ensure proper spinal alignment. Contemporary mattresses make use of sophisticated materials, including memory foam, breathable fabrics, and zoned support systems, which not only ensure elevated levels of comfort but also durability and temperature regulation. They come in a range of diverse sizes, firmness levels, and constructions, each tailored to specific user preferences and health needs.

Key Applications Across Industries:

Mattresses play a critical role in residential settings, wherein the item is a basic attribute of a bedroom, guest room, or children's sleeping room. More than providing just mere rest, mattresses are directly responsible for adequate sleep quality, posture correction, pain alleviation, and long-term health outcomes. Various orthopedic mattresses exist that are used by people with different issues affecting their backs and joints, with special targeted support and pressure relief.

Within the industry, mattresses are highly indispensable assets for hotels, resorts, service apartments, and homestays. High-quality mattresses contribute to guest comfort, influence occupancy satisfaction, and become a key competitive differentiator in premium and luxury hotel segments.

Hospital mattresses are designed for healthcare purposes, having various features such as variable support adjustment, anti-bacterial fabrics, moisture resistance, and pressure-relieving zones that help prevent bedsores and improve the recovery process. Medical and rehabilitation facilities also use therapeutic mattresses developed for long-term lying support. Nowadays, mattresses are also used in institutions like dormitories, hostels, defense housing, and accommodations provided to workers, where durability and hygiene are the priorities.

The trend of multi-functional furniture has grown in compact houses, where sofa beds, Murphy beds, and trundle mattresses expand mattress applications. Mattresses currently also serve lifestyle purposes: fitness stretching, meditation lounges, kids' playrooms, RVs, and camping setups. The wide adaptability of mattress types, such as spring, foam, latex, and hybrids, make them suitable for a broad spectrum of environments, budgets, and user needs.

What the Expert Says: Market Overview & Growth Drivers

The global mattress market reached a value of USD 41.1 Billion in 2024. According to IMARC Group, the market is projected to reach USD 66.7 Billion by 2033, at a projected CAGR of 5.48% during 2025-2033. The factors driving this market are structural, demographic, and lifestyle. Key among them is the growing real estate sector that encompasses residential housing, home renovation, and rental accommodation. This will lead to an increase in urbanization and disposable incomes, ensuring that customers are willing to invest more in bedroom comfort, upgrading from basic or traditional mattresses to premium and specialized variants.

This expansion in the hospitality industry is due to increased tourism, business travel, and the development of new hotels; therefore, it creates a constant demand for commercial-grade, durable mattresses. Hotels also replace mattresses rather frequently as part of quality upgrades, thus creating recurring replacement cycles.

Another key force is health and wellness trends. Increased awareness about sleep quality, ergonomic support, and musculoskeletal health has triggered demand towards orthopedic, memory foam, latex, and hybrid mattresses. Comfort-seeking buyers increasingly demand breathable materials, temperature regulation, anti-allergy fabrics, and pressure-relief technologies that usher in the pace of premiumization.

E-commerce has transformed mattress-buying behavior around the globe. Access has improved, product choices have widened, and marketing strategies have been reshaped by the emergence of bed-in-a-box brands and direct-to-consumer platforms. This was also a driver for innovation in compressible foam and hybrid designs with good shippability.

Other factors contributing to an increase in mattress adoption include growth in population, students' and workforce mobility, and expansion of institutional housing. Additionally, the durability and replacement cycle of mattresses-usually 7-10 years-create steady repeat demand. Sustainable materials such as natural latex, organic cotton, and recycled foam are gaining traction, driven by environmentally conscious consumers.

The convergence of real estate development, hospitality expansion, health awareness, e-commerce penetration, and material innovation forms the core of global mattress market growth in its entirety.

Case Study on Cost Model of Mattress Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale mattress manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed mattress manufacturing plant in India. This plant is designed to manufacture 100,000 units of mattresses annually.

Manufacturing Process: Material preparation, assembly, cushioning, finishing, and rigorous quality testing are involved in the manufacture of mattresses to achieve durability, comfort, and ergonomic performance. Manufacturing thus commences with core selection, which depends on the type of mattress desired: innerspring, foam, latex, hybrid, or orthopedic. For spring mattresses, high-carbon steel wires are coiled into springs, heat-tempered for strength, and assembled into either Bonnell, pocketed, or continuous coil units. In the case of foam mattresses, manufacturing begins with the blending of polyurethane chemicals in controlled reactors to produce foam blocks that are cured, cut, and shaped. Latex mattresses involve natural or synthetic latex poured into molds using either the Dunlop or Talalay process. Once the core is ready, layers of comfort materials like memory foam, latex, quilting foam, felt pads, or fiberfill are added to enhance softness, support, and airflow. These layers are precision-cut and laminated or stitched together as dictated by the design. The preparation of the upper surface—the ticking fabric—is made from knitted, woven, or quilted textiles. Advanced quilting machines also stitch together layers of fabric and foam, creating a plush top panel. The mattress components are then assembled: adding edge supports, stacking the layers, and sealing the perimeter by automated tape-edge machines. On hybrid mattresses, pocket springs are combined with foam or latex layers by using adhesive bonding systems. Mattresses, after being assembled, are compressed and roll-packed using hydraulic compression machines for foam and hybrid types to facilitate easy transportation. Each unit is subjected to stringent quality checks regarding firmness testing, durability simulation, fabric inspection, and dimensional accuracy. After this, the finished mattresses are labeled, packaged, and prepared for distribution.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

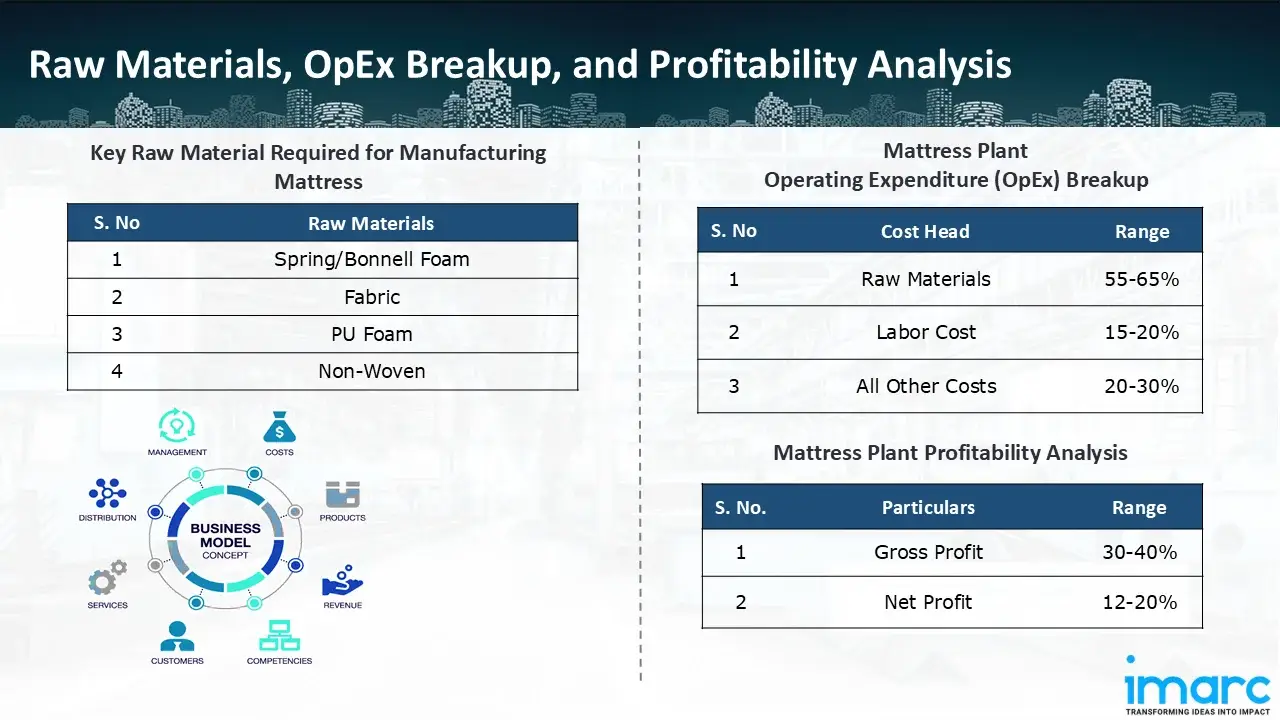

The basic raw materials required for mattress manufacturing include:

- Spring/Bonnell Foam

- Fabric

- PU Foam

- Non-Woven

Machine Section or Lines Required:

- Spring Coiling

- Quilting

- Assembly

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in mattress manufacturing plant ranges between 55-65%, labor cost ranges between 15% to 20%, and all other costs ranges between 20-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 12-20% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the mattress manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 100,000 units of mattresses annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, the Posture Advance Range, Sealy India Trading Pvt. Ltd.'s most recent product, is a major addition to the company's line of high-end mattresses. This new range, which was created in India with worldwide experience, is a complement to Sealy's current Posturepedic and PostureSense collections, which together include more than 20 items intended for the best possible sleep.

- In February 2025, Tempur Sealy International, Inc. announced that it has completed its previously announced acquisition of Mattress Firm Group Inc., the nation's largest mattress specialty retailer.

- In February 2024, Casper introduced a revamped mattress lineup, including the Casper One. The Casper One is made to ease pressure and support sleepers without feeling overly soft because to its three layers of foam and medium firm feel. Budget shoppers find it appealing because it is one of Casper's most reasonably priced mattresses.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104