PVC Panel Manufacturing Cost Analysis: Shaping Spaces, Shaping Margins

What is PVC Panel?

PVC panels are lightweight, durable building materials made from polyvinyl chloride using extrusion or molding processes. They are available as rigid or semi-rigid sheets designed primarily for wall and ceiling cladding, partitions, and decorative finishes. Known for their excellent resistance to moisture, chemicals, termites, and corrosion, PVC panels offer a smooth surface and a clean, polished look that’s easy to maintain. Available in an extensive range of colors, textures, and patterns, these panels serve as a practical alternative to traditional materials like wood, plaster, or tiles. Whether in homes, offices, or industrial environments, PVC panels provide a cost-effective and aesthetically appealing solution for both new constructions and renovation projects.

Key Applications Across Industries:

PVC panels have become a go-to choice across residential, commercial, and industrial sectors thanks to their versatility, low maintenance, and longevity.

In residential buildings, they are frequently used for interior wall and ceiling cladding in living rooms, bedrooms, kitchens, bathrooms, and balconies. Their strong resistance to moisture makes them especially ideal for wet areas such as washrooms, bathrooms, and laundry spaces, places where conventional materials like plaster or wood can deteriorate over time. PVC ceiling panels are also used to conceal electrical wiring, air ducts, and uneven surfaces, creating a neat, modern finish.

In commercial settings, such as offices, hotels, hospitals, retail stores, and educational institutions, PVC panels are valued for their hygienic, easy-to-clean surfaces. They are especially popular in healthcare facilities, laboratories, and food preparation areas where cleanliness is a priority. In hospitality and retail interiors, decorative PVC panels help enhance aesthetic appeal without requiring extensive structural changes.

In industrial environments, including factories, warehouses, clean rooms, and cold storage units, PVC panels are appreciated for their resistance to chemicals, humidity, and temperature variations. Their lightweight nature and quick installation make them suitable for temporary partitions, modular setups, and prefabricated structures. Beyond buildings, PVC panels are even used in transportation infrastructure like airports and railway stations, where durability and minimal upkeep are essential. Overall, PVC panels successfully combine functionality with design flexibility, making them suitable for nearly every type of space, from homes to heavy-duty industrial facilities.

What the Expert Says: Market Overview & Growth Drivers

The global PVC panel market reached a value of USD 3.90 Billion in 2024. According to IMARC Group, the market is projected to reach USD 6.90 Billion by 2033, at a projected CAGR of 6.5% during 2025-2033. The global market for PVC panels continues to grow, driven by a combination of expanding construction activity, rising urbanization, and the increasing demand for cost-effective and efficient building materials. Rapid population growth in emerging economies has fueled residential and commercial construction projects, boosting the need for reliable wall and ceiling solutions. PVC panels, with their affordability, fast installation, and low maintenance, have become a preferred choice for developers and contractors seeking practical alternatives to traditional materials.

The trend toward renovation and remodeling also plays a major role. Homeowners and businesses alike are looking for materials that can refresh interiors quickly, without major structural changes or long downtime. PVC panels fit this demand perfectly, they’re easy to install, require little surface preparation, and deliver an instant visual upgrade. Their wide variety of colors, textures, and finishes also allows for aesthetic customization that fits different styles and budgets.

Beyond convenience, durability and performance are key growth factors. PVC panels stand up well to moisture, pests, and corrosion, making them ideal for both humid and dry climates. Their long service life and minimal maintenance reduce long-term costs, a major advantage in sectors like healthcare, hospitality, and retail, where appearance and hygiene are equally important.

Another emerging factor is sustainability. Modern manufacturing techniques allow PVC panels to incorporate recycled materials while maintaining high performance and longevity. Continuous advancements in extrusion technology and material formulation have improved their quality, fire resistance, and surface finish, broadening their use across industries.

Finally, the rise of modular and prefabricated construction has created new opportunities for lightweight, standardized materials like PVC panels. When combined with the ongoing global surge in construction and renovation activity, these benefits make PVC panels a key component of modern, efficient, and design-focused building systems.

Case Study on Cost Model of PVC Panel Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale PVC panel manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed PVC panel manufacturing plant in India. This plant is designed to manufacture 1 million panels of PVC panel annually.

Manufacturing Process: The manufacturing of PVC panels involves a carefully controlled series of steps, compounding, extrusion, cooling, and finishing, designed to produce lightweight, durable, and visually consistent products. The process begins with compound preparation, where polyvinyl chloride (PVC) resin is blended with additives such as stabilizers, plasticizers, impact modifiers, fillers, and pigments. Each additive serves a specific purpose: stabilizers enhance heat resistance, plasticizers improve flexibility, and pigments determine the final color and appearance. The mixture is thoroughly blended to ensure even dispersion, resulting in a uniform compound with consistent performance characteristics such as rigidity, surface smoothness, and fire resistance.

Next, the compounded PVC material enters the extrusion stage. It is fed into a single-screw or twin-screw extruder, where controlled heat and pressure melt the compound into a viscous form. The molten PVC is then pushed through a precisely engineered die that shapes it into flat panels with defined width, thickness, and internal features. Many panels are designed with hollow cores to reduce weight while maintaining structural strength and insulation efficiency. As the hot, newly formed panel exits the die, it passes over a vacuum calibration table, which ensures exact dimensions and a smooth, uniform surface. The panel is then cooled using water spray or immersion systems to solidify its structure and preserve its shape. Once cooled, the panels are pulled through haul-off units and cut to standard lengths using automated cutting equipment. At this stage, additional finishing operations may be applied, such as printing, lamination, or embossing, to achieve decorative effects like wood-grain patterns, matte textures, or high-gloss finishes.

Throughout production, quality control checks are performed to verify key parameters including dimensional accuracy, surface quality, mechanical strength, and fire resistance. Panels that meet the required standards are then stacked, packaged, and prepared for distribution.

Modern PVC panel manufacturing facilities emphasize automation, energy efficiency, and waste recycling. By optimizing material use and reducing production waste, manufacturers ensure that PVC panels are not only cost-effective and durable but also aligned with contemporary sustainability standards.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

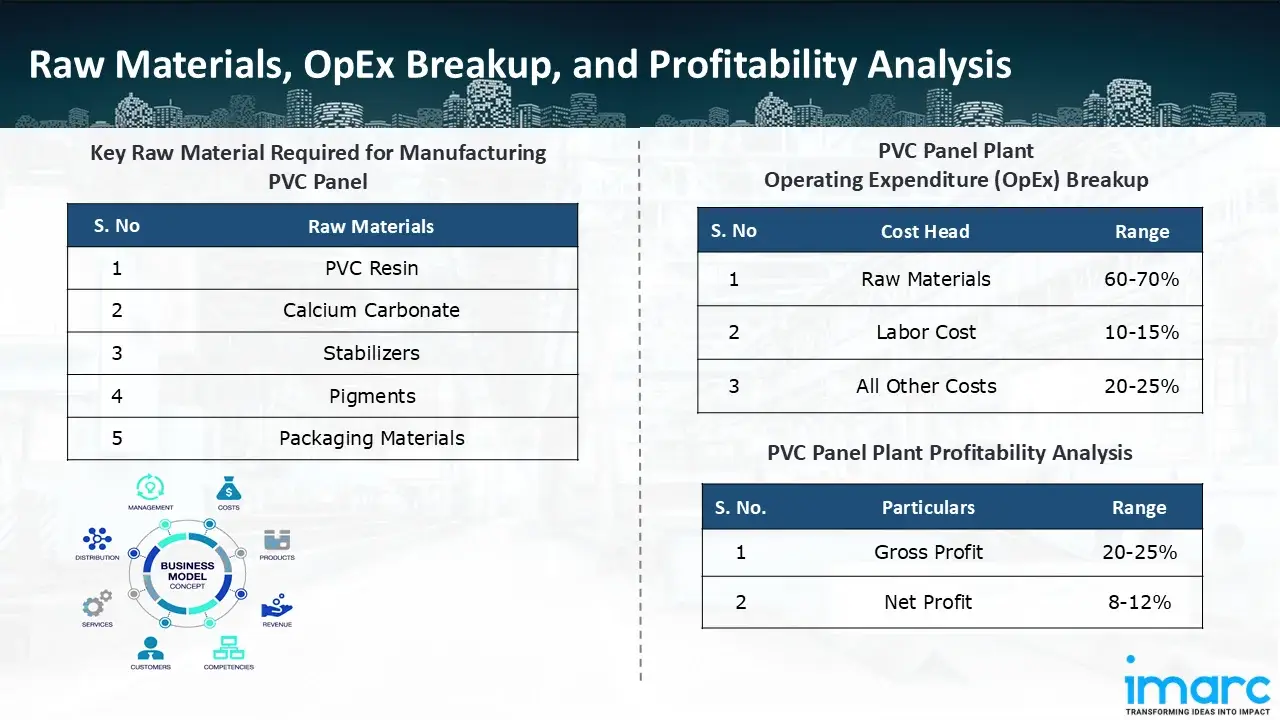

The basic raw materials required for PVC panel manufacturing include:

- PVC Resin

- Calcium Carbonate

- Stabilizers

- Pigments

- Packaging Materials

Machine Section or Lines Required:

- Mixing

- Extrusion

- Calendaring

- Cutting

- Embossing

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in PVC panel manufacturing plant ranges between 60-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 20-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-25%, and net profit lie between the range of 8-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the PVC panel manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 1 million units of PVC panel annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In February 2025, Texas polyvinyl chloride (PVC) manufacturer Westlake announced its plans to begin production at a new molecular-focused PVC plant in 2026. The plant, initially announced in May 2024, is an addition to its Wichita Falls, Texas, facility. The project will include four production lines to Westlake's current molecular-oriented PVC production, though the company did not detail its capacity for the new plant or its overall capacity for the specialty PVC.

- In September 2024, Reliance Industries Limited has announced its plans to build new polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) plants at the company’s existing sites in Dahej and Nagothane.

- In June 2024, VERSATEX opened a brand-new, 96,500-square-foot PVC manufacturing facility. This initiative is anticipated to create roughly 80 new jobs in the area in addition to tripling the company's manufacturing capacity.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104