Top Factors Driving Growth in the Industry 4.0 Market

Introduction to the Industry 4.0 Industry:

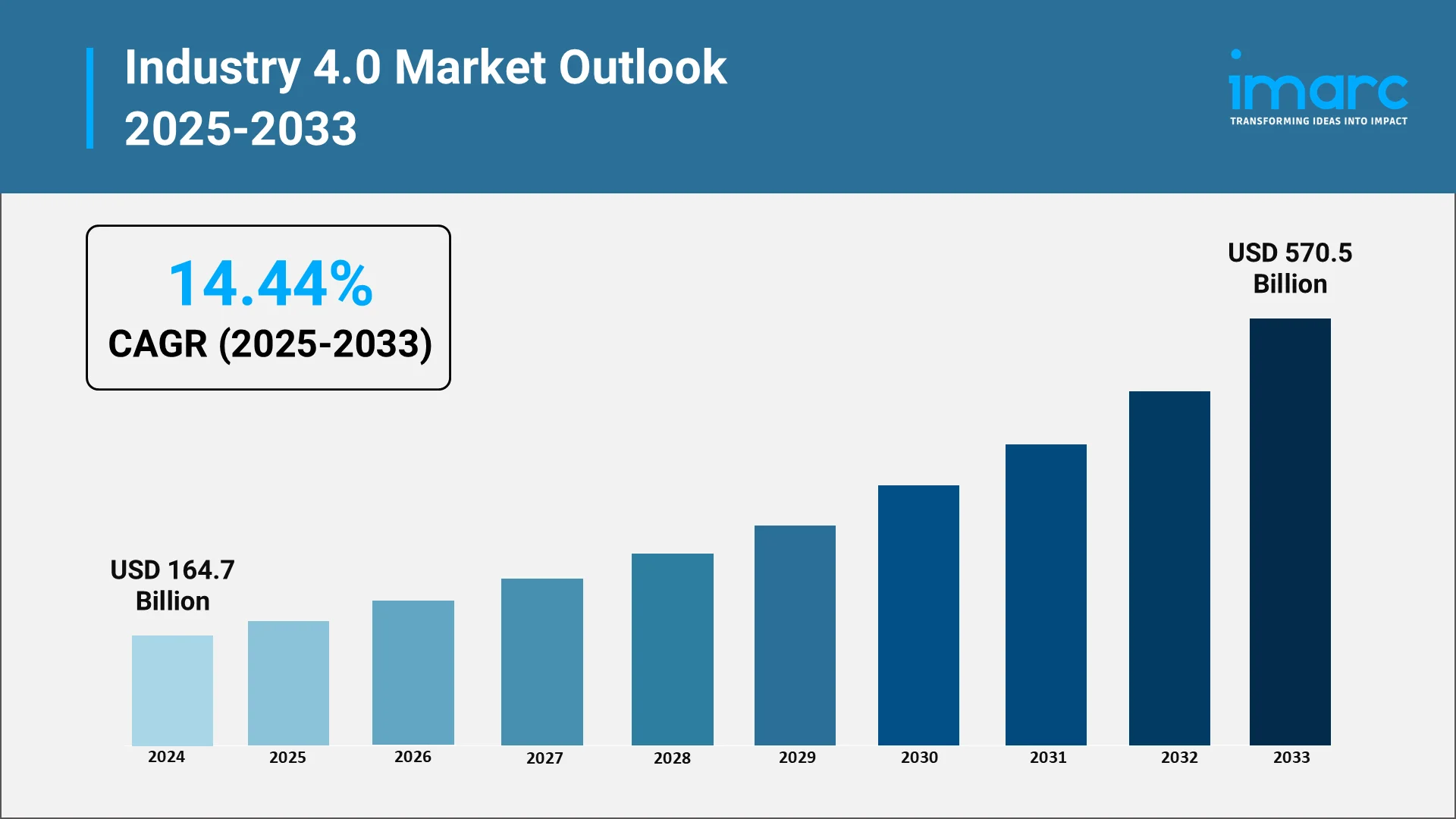

The global Industry 4.0 market is experiencing strong momentum, propelled by the integration of smart technologies across manufacturing, logistics, and energy sectors. With automation, connectivity, and data intelligence at its core, Industry 4.0 is reshaping how enterprises design, produce, and deliver products. According to IMARC Group, the global industry 4.0 market size reached USD 164.7 Billion in 2024. Looking forward, the market is projected to reach USD 570.5 Billion by 2033, exhibiting a growth rate (CAGR) of 14.44% during 2025-2033. Germany, the U.S., India, and China remain frontrunners in adopting industrial digitalization. As factories transition toward intelligent ecosystems, investments in AI, robotics, IoT, and cyber-physical systems continue to surge, positioning Industry 4.0 as a cornerstone of global competitiveness.

Explore in-depth findings for this market, Request Sample

Adoption of Internet of Things (IoT) Technologies:

IoT serves as the backbone of Industry 4.0, enabling real-time data exchange, remote monitoring, and predictive maintenance. Manufacturers increasingly deploy IoT sensors across assembly lines, warehouses, and equipment to enhance transparency and reduce downtime. Some of the key players in the market include 3D Systems, Inc., ABB Ltd, Cisco Systems Inc., DENSO Products and Services Americas, Inc., FANUC America Corporation, Honeywell International Inc., International Business Machines Corporation, PTC Inc., Rockwell Automation, SAP SE, Schneider Electric, and Siemens AG.

Predictive analytics powered by IoT helps identify faults before failures occur, thereby cutting maintenance costs. In India, the Ministry of Heavy Industries (MHI) announced key progress under the SAMARTH Udyog Bharat 4.0 Initiative in December 2024, launched to strengthen India’s manufacturing competitiveness through Industry 4.0 adoption. Four SAMARTH Centres — including C4i4 Lab Pune, IITD-AIA Foundation for Smart Manufacturing (IIT Delhi), I-4.0 India @ IISc Bengaluru, and CMTI Bengaluru — have been established, with 10 additional Industry 4.0 experience centres approved nationwide. The program has achieved over 100 digital maturity assessments, 500+ improvement initiatives, and 5,000 professionals trained, alongside development of 14 smart solutions, 6 smart technologies, and the Industry 4.0 Maturity Model (I4MM) to evaluate readiness among Indian manufacturers, particularly MSMEs, in their digital transformation journey. As IoT networks expand, they are laying the groundwork for autonomous operations and connected supply chains.

Key Growth Drivers in the Industry 4.0 Industry:

- Automation and AI Integration: The integration of robotics, AI, and machine learning is reshaping industrial operations, driving precision and efficiency. Smart robots and autonomous systems handle repetitive tasks, allowing human workers to focus on innovation and oversight. These advancements are reducing waste, optimizing workflows, and enabling continuous improvement across production environments.

- Predictive Maintenance and Efficiency Gains: Digital twins and AI-powered analytics give manufacturers real-time insights into equipment performance. By forecasting potential failures, companies can schedule maintenance proactively, reducing costly downtime. This predictive approach improves overall productivity and ensures higher equipment reliability.

- Demand for Customization: Modern consumers increasingly expect personalized products without premium pricing. Industry 4.0 technologies make this feasible by enabling flexible, data-driven manufacturing systems. Businesses can now produce small batches efficiently, meeting diverse demands while maintaining profitability.

- Workforce Upskilling: The rise of smart factories is creating strong demand for skilled professionals in automation, AI, and analytics. Governments and corporations are investing heavily in technical education and training programs. This focus on digital literacy is vital to building a future-ready workforce capable of managing advanced systems.

- Sustainability Goals: Industry 4.0 aligns industrial growth with environmental responsibility through energy-efficient technologies. Smart grids, resource monitoring, and waste management systems help reduce emissions and material waste. These innovations support global efforts toward achieving carbon neutrality and sustainable manufacturing.

Government Support/Initiatives of the Industry 4.0 Industry:

Governments worldwide are accelerating Industry 4.0 adoption through strategic funding, policy frameworks, and digital infrastructure development. Currently, Europe currently dominates the market holding a market share of over 35.8% in 2024. Germany’s Industry 4.0 Strategy continues to guide industrial modernization through collaborative innovation hubs and academic partnerships.

The United States, under its Manufacturing USA program, supports regional innovation centers focused on robotics and cyber-physical systems. Meanwhile, Japan’s Society 5.0 vision integrates Industry 4.0 principles with human-centric AI to build resilient supply chains. These initiatives collectively drive global standardization, technology transfer, and innovation adoption across industrial ecosystems. India’s Digital Manufacturing Mission and Make in India 2.0 initiatives incentivize automation and R&D in smart factories. In October 2024, Prime Minister Narendra Modi inaugurated the Indian Institute of Skills (IIS) in Mumbai, designed to train 5,000 students annually in cutting-edge Industry 4.0 technologies such as factory automation, AI, data analytics, digital manufacturing, and mechatronics. Established under a Public-Private Partnership between the Ministry of Skill Development and Entrepreneurship and Tata IIS, the institute will offer six advanced courses, including EV Battery Specialist and Additive Manufacturing, with support from 15+ global OEMs for hands-on industry training.

Rising Adoption of Cloud Computing in Manufacturing:

Cloud computing is revolutionizing industrial operations by providing scalable infrastructure, advanced analytics, and collaborative design environments. According to recent survey records, 92% of manufacturers believe smart manufacturing will be their key competitive driver in the next three years. In a similar way, 85% of the respondents believe that their smart manufacturing initiatives will reshape production, boost adaptability, and attract skilled talent.

Cloud integration streamlines supply chains, enabling manufacturers to manage distributed operations from a single dashboard. Platforms such as AWS IoT SiteWise, Microsoft Azure IoT Hub, and Siemens MindSphere are enabling smart factories to store, process, and analyze real-time data securely. For instance, In October 2024, Cognizant signed a Strategic Collaboration Agreement (SCA) with Amazon Web Services (AWS) to advance smart manufacturing and Industry 4.0 capabilities across industrial, automotive, life sciences, and consumer goods sectors. The partnership focuses on deploying IoT, AI, and cloud-powered solutions—including digital twins, edge computing, and generative AI—to optimize factory operations, enable predictive maintenance, and enhance real-time decision-making. By bridging the gap between IT and OT (Operational Technology), cloud solutions empower predictive maintenance, resource optimization, and continuous innovation.

Impact of 5G Connectivity on Industrial Operations:

5G technology is unlocking ultra-low latency, high-speed data transmission essential for autonomous robots, remote maintenance, and AR-based training. With real-time machine-to-machine communication, manufacturers can synchronize operations across complex assembly lines and connected warehouses. 5G’s combination of bandwidth, reliability, and security will catalyze large-scale digital transformation, allowing enterprises to scale automation while enhancing worker safety and system uptime. In May 2025, UST signed a Memorandum of Understanding (MoU) with T-Works, India’s largest prototyping center, to accelerate Industry 4.0 innovation across the manufacturing, semiconductor, and automotive sectors. The partnership integrates UST’s AI, IoT, and systems integration expertise with T-Works’ prototyping ecosystem, enabling startups and enterprises to achieve up to 45% faster hardware-to-digital integration and 40% reduction in R&D costs.

Edge computing acts as the critical backbone supporting 5G-enabled industrial ecosystems. By processing data closer to the source, it reduces dependency on centralized cloud systems, enabling real-time analytics for robotics, predictive maintenance, and production optimization. This distributed computing model enhances the responsiveness of automated systems and ensures business continuity even in low-connectivity environments. As manufacturers adopt AI-driven quality control and autonomous logistics, the synergy between 5G and edge infrastructure is accelerating deployment of smart factories worldwide. In 2024, global spending on edge computing (hardware, software, services, etc.) was estimated at USD 228 Billion, up ~14% from 2023.

Opportunities and Challenges in the Industry 4.0 Industry:

The shift toward digital manufacturing presents immense opportunities in smart robotics, industrial IoT, and edge computing. In 2024, the global IIoT market size was estimated at USD 289.0 billion, and is forecast to reach USD 847.0 billion by 2033, growing at a CAGR of 12.7%. Startups and established firms alike are leveraging AI-based quality control, real-time analytics, and connected machinery to enhance competitiveness.

However, integration complexity and high capital expenditure pose barriers for small and medium enterprises (SMEs). Cybersecurity risks have also emerged as a critical concern, with increasing exposure of operational networks to cyber threats. Bridging the skills gap remains another challenge, requiring targeted workforce training in data science and automation engineering. To address the skill-gap issue, in August 2025, IIM Calcutta launched the Advanced Programme in Smart Manufacturing Leadership (APSML) to support India’s Industry 4.0 revolution and strengthen the nation’s smart manufacturing ecosystem. Designed in collaboration with VCNow Executive Education, the eight-month executive course targets senior professionals and plant heads, focusing on AI, IoT, robotics, digital twins, and cloud computing for operational excellence and digital transformation. Balancing innovation with affordability and resilience will define the sector’s trajectory in the next decade.

Some of the recent market developments include:

- In August 2025, Tech Mahindra announced a strategic partnership with Dixon Technologies (India) Limited to implement AI-powered Industry 4.0 automation across all of Dixon’s manufacturing plants and R&D centers in India. The collaboration focuses on deploying smart factory solutions, integrating end-to-end digital systems to enhance productivity, eliminate data silos, and improve decision-making through real-time analytics.

- In July 2025, SiMa.ai announced a go-to-market collaboration with Cisco to accelerate edge AI adoption for Industry 4.0. The partnership integrates SiMa.ai’s Modalix AI platform, known for its high-performance and energy efficiency, with Cisco’s IE3500 ruggedized switches to deliver low-latency, secure, and scalable edge AI solutions across sectors like manufacturing, logistics, energy, and transportation.

- In February 2025, Nokia introduced MX Context, an AI-powered contextual awareness solution designed to accelerate Industry 4.0 adoption by integrating sensor fusion technology for intelligent automation and operational excellence. Launched at MWC25, the platform unifies multimodal sensor data to eliminate data silos, enhance worker safety, and optimize industrial resources, offering two primary suites—tracking and positioning and worker safety—that use real-time AI inferencing for situational awareness.

- In February 2025, Ericsson deployed its Private 5G solution at JLR’s Solihull plant to accelerate the company’s digital manufacturing transformation and advance its Industry 4.0 ambitions. The high-speed, low-latency network enables AI, machine learning, IoT sensors, and vision systems to optimize production for Range Rover vehicles, replacing traditional wired infrastructure to “cut the copper” and enhance operational agility.

Future Outlook for the Industry 4.0 Industry:

The global Industry 4.0 landscape is poised for exponential growth as manufacturers embrace digital transformation. The integration of AI, 5G, cloud platforms, and robotics will foster self-optimizing production systems and hyper-connected supply chains. Markets in Asia-Pacific are expected to witness the fastest adoption, driven by smart infrastructure investments and government-led modernization programs. Sustainability will remain central, with digital tools optimizing energy usage and carbon footprints. As interoperability standards mature, Industry 4.0 will extend beyond factories to logistics, agriculture, and utilities, driving inclusive industrial growth. By 2033, Industry 4.0 will evolve into a fully intelligent, data-driven industrial ecosystem powering global competitiveness.

Why Choose IMARC for Industry 4.0 Market Insights?

IMARC offers data-driven, sector-specific insights to help businesses, investors, and policymakers make informed decisions in the rapidly evolving Industry 4.0 landscape.

- Unmatched Domain Expertise: Extensive experience across automation, IoT, AI, robotics, and manufacturing analytics ensures deep understanding of the Industry 4.0 value chain.

- Real-Time Market Intelligence: Access continuously updated data from verified industrial sources, regulatory bodies, and government programs across global markets.

- Strategic Forecasting Models: Proprietary forecasting tools assess emerging trends, adoption rates, and revenue potential through 2033.

- Regional and Segment-Level Analysis: Detailed insights by technology type, end-use industry, and geography help identify high-growth clusters and investment corridors.

- Competitive Benchmarking: Comprehensive profiling of key players, innovation pipelines, and M&A activity to map leadership strategies in industrial automation.

- Policy and Initiative Tracking: Dedicated coverage of global and regional initiatives—such as Make in India 2.0, Industry 4.0 Roadmaps, and Society 5.0—shaping sector development.

- Decision Support for Stakeholders: Actionable recommendations tailored to manufacturers, investors, and technology providers navigating digital transformation.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104

.webp)