Banana Powder Cost Model: Detailed Profitability Analysis

.webp)

What is Banana Powder?

Banana powder is a dry, fine, nutrient-dense substance created by dehydrating ripe or unripe bananas using methods like spray drying, freeze drying, or drum drying. It acts as an easy and shelf-stable substitute for fresh bananas, preserving most of their essential nutrients such as potassium, magnesium, vitamin B6, and dietary fiber.

Key Applications Across Industries:

The production process includes choosing premium bananas, removing their peels, cutting them into slices, and drying them to an optimal moisture content before milling into a fine powder. Based on the final application, flowability and stability might be improved by including additives or anti-caking agents. Banana powder is widely used in various sectors, such as food and drinks, pharmaceuticals, cosmetics, and livestock feed. In the food industry, it is frequently utilized as an ingredient in baby food, baked goods, dairy products, smoothies, sweets, and ready-to-drink beverages, owing to its natural sweetness, taste, and nutritional value. The pharmaceutical sector employs it in dietary supplements and digestive wellness items, whereas in cosmetics, it acts as a natural scent and antioxidant ingredient. Additionally, banana powder offers a valuable way to use overripe or excess bananas, minimizing agricultural waste and promoting sustainable processing methods. As consumer demand for natural, organic, and functional food ingredients increases, banana powder has attracted worldwide interest as a multifunctional and health-promoting product. It also holds an important position in the global functional food movement, providing nutritional and economic advantages to growers, processors, and manufacturers in both developing and developed markets.

What the Expert Says: Market Overview & Growth Drivers

The global banana powder market reached a value of USD 1,304.7 Million in 2024. According to IMARC Group, the market is projected to reach USD 2,195.2 Million by 2033, at a projected (CAGR) of 5.95%during 2025-2033. The global banana powder market is growing steadily, fueled by a blend of health-focused consumer habits, sustainability objectives, and increasing uses in various sectors.

A major market driver is the growing demand for natural and functional food ingredients, as consumers increasingly move away from synthetic additives and opt for clean-label, nutrient-dense options. The high potassium levels, inherent sweetness, and simple digestibility of banana powder contribute to its popularity in health foods, baby nutrition, and athletic supplements. The banana powder market is predominantly driven by the food and beverage sector, especially in bakery, dairy, and baby food uses. The increasing appeal of smoothie blends, ready-to-drink drinks, and nutritional powders in North America, Europe, and Asia-Pacific continues to drive demand. Moreover, the rising use of banana powder in cosmetics and personal care items, due to its moisturizing and antioxidant qualities has created new business opportunities. From a supply standpoint, the product enhances value in banana-producing areas like India, the Philippines, Ecuador, and Africa, where excess or imperfect bananas can be utilized rather than discarded, thus fostering agricultural sustainability and boosting rural income. Moreover, improvements in food drying and powder processing methods, especially freeze-drying and spray-drying, have enhanced product quality, longevity, and manufacturing efficiency. Government assistance for food processing sectors and the worldwide increase in vegan, gluten-free, and organic product trends serve as further growth drivers. With global consumers focusing on convenience, health, and environmentally friendly options, banana powder is becoming a viable and lucrative niche within the larger market for natural ingredients and functional foods.

Case Study on Cost Model of Banana Powder Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale banana powder manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed banana powder manufacturing plant in India. This plant is designed to produce 300 kg of banana powder per hour.

Manufacturing Process: Several meticulously regulated procedures are used in the production of banana powder in order to maintain the ripe bananas' flavor, aroma, and nutritional value while turning them into a stable, usable powder. The first step in the process is choosing premium, fully ripe bananas, usually from types like Cavendish or Nendran that have a high solid content and a naturally sweet flavor. To get rid of dirt, pesticides, and outer layers, the chosen bananas are carefully cleaned and peeled. After being peeled, the bananas are cut into uniform pieces to guarantee even drying. To stop enzymatic browning and maintain color, they are then blanched or treated with a solution of sodium metabisulfite or citric acid. Drying, an essential step in the creation of powder, is applied to the pretreated banana slices. A variety of drying methods, including spray drying, freeze drying, drum drying, and cabinet drying, can be employed, depending on the production scale and the desired product quality. Because of its effectiveness and capacity to produce fine, uniform powder, spray drying is frequently chosen for commercial production. To achieve the desired particle size distribution, the dried banana slices are first ground into a uniformly fine powder using hammer mills or pulverizers. This powder is then sieved. To ensure a long shelf life and freshness, the finished banana powder is sealed in airtight, moisture-proof packaging to keep out oxidation and moisture. Strict quality control is upheld throughout the process to preserve vital nutrients like potassium, dietary fibre, and natural sugars, allowing banana powder to be used in beverages, baby food, baked goods, and health supplements.

Get a Tailored Feasibility Report for Your Project Request Sample

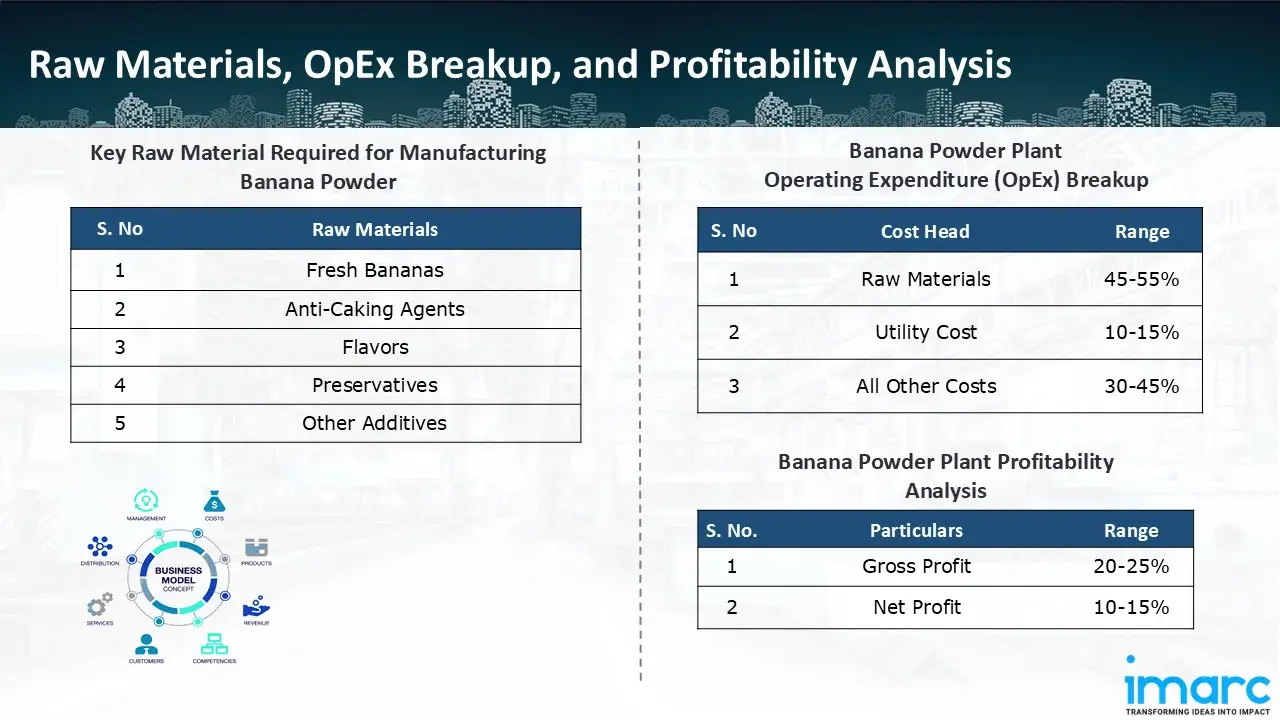

Raw Material Required:

The basic raw materials required for banana powder manufacturing include:

- Fresh Bananas

- Anti-Caking Agents

- Flavors

- Preservatives

- Other Additives

Machineries Required:

- Banana Peeler

- Banana Slicer

- Sorting Conveyor

- Fruit Washer

- Blanching Machine

- Multi-layer Mesh Belt Dryer

- Hot Air Dryer

- Spray Dryer

- Hammer Mill

- Pin Mill

- Pulverizer

- Vibratory Sieve

- Ribbon Blender

- Filling Machine

- Sealing Machine

- Labeling Machine

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a banana powder manufacturing plant ranges between 45-55%, utility cost ranges between 10% to 15%, and all other costs ranges between 30-45% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-25%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the banana powder manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 300 kg of banana powder per hour, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In February 2025, Dole Speciality Ingredients (DSI), a branch of Dole Asia Holdings, has partnered with Givaudan to distribute an upcycled Green Banana Powder ingredient. The addition will broaden the selection of clean-label emulsification and texturiser solutions offered by Givaudan's Sense Texture line.

- In July 2024, The International Agriculture Group (IAG) introduced a novel component that contains a significant amount of dietary fiber-resistant starch, a prebiotic. RS2 resistant starch, which makes up at least 65% of NuBana N200 Green Banana Flour, has been demonstrated to offer a variety of health advantages based on daily consumption.

- In March 2024, OLEHENRIKSEN introduced Banana Bright+ Instant Glow Moisturiser, a new skincare product that has been rigorously evaluated to improve the appearance of makeup, brighten skin both instantly and over time, and minimise wrinkles and fine lines. The product is intended to give off a warm, golden glow. It has iridescent hues inspired by banana powder, gold-complexed vitamin C, and hydrating ingredients including Scandinavian cloudberry seed oil and hyaluronic acid.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104