Apple Fruit Juice Cost Model: Assessing the Cost and Profits

What is Apple Fruit Juice?

Apple juice is among the most popular fruit drinks in the world, appreciated for its crisp flavor, inherent sweetness, and health advantages. Apple juice is made by pressing fresh apples and filtering the resulting liquid, containing vital nutrients like vitamin C, potassium, antioxidants, and polyphenols that support immune function, cardiovascular health, and hydration.

Key Applications Across Industries:

Based on manufacturing techniques, apple juice can be clear, murky, or concentrated, with each type presenting unique taste profiles and longevity attributes. Filtered juice is processed to eliminate pulp, providing a clear look, whereas cloudy juice keeps inherent apple particles, maintaining higher levels of fiber and bioactive substances. The production procedure includes sorting, washing, crushing, pressing, enzymatic treatment, filtration, pasteurization, and packaging, guaranteeing product safety and stability. Certain manufacturers also create apple juice concentrate, which is sent to beverage companies globally for reconstitution and mixing. Apple juice acts as a flexible foundation for drinks, cocktails, health beverages, and food recipes because of its gentle taste and inherent acidity. It is especially favored in North America, Europe, and Asia-Pacific, where increasing health consciousness fuels the desire for natural, fruit-derived beverages. Due to the popularity of organic, cold-pressed, and preservative-free options, apple juice has transformed from a basic drink into a high-quality health beverage. Bolstered by robust raw material resources in apple-producing areas such as the U.S., China, Poland, and India, the worldwide apple juice sector continues to play a crucial role in the fruit manufacturing and non-alcoholic drink industries.

What the Expert Says: Market Overview & Growth Drivers

The global apple juice market reached a value of USD 18.7 Billion in 2024. According to IMARC Group, the market is projected to reach USD 28.6 Billion by 2033, at a projected CAGR of 4.46% during 2025-2033. The global apple fruit juice market is experiencing steady expansion fueled by heightened health awareness, growing consumption of fruit beverages, and innovations in juice manufacturing and packaging technologies.

A major factor is the increasing consumer demand for natural and functional drinks, as individuals look for options beyond carbonated soft drinks. Apple juice, naturally abundant in antioxidants and devoid of artificial colors or flavors, fits this trend perfectly. Additionally, the worldwide demand for clean-label and organic items has motivated leading brands to offer preservative-free and entirely pure apple juice options. The growth of the food and beverage sector, along with the rise of e-commerce and contemporary retail, is further improving product availability. Increasing disposable incomes in developing countries like India and China are further enhancing the demand for convenient, nutritious drinks. In advanced markets like the U.S. and Europe, innovations including cold-pressed, NFC (not-from-concentrate), and fortified apple juices are transforming consumer tastes and broadening premium product categories. A significant factor contributing to growth is the globalization of apple farming and manufacturing, which has secured consistent supply chains and year-round access. Advancements in pasteurization, aseptic packaging, and juice concentration have prolonged shelf life and minimized waste, promoting export-focused growth. Moreover, the increasing trend of plant-based diets and health-oriented living has led to apple juice becoming a favored option for consumers looking for nutrient-dense hydration alternatives. Along with sustainability efforts in fruit sourcing and packaging, these elements are setting the apple juice market up for consistent growth globally in the future.

Case Study on Cost Model of Apple Fruit Juice Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale apple fruit juice manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed apple fruit juice manufacturing plant in India. This plant is designed to produce 1,500 tons of apple fruit juice annually.

Manufacturing Process: The process of making apple juice consists of a series of exact steps designed to extract, clarify, and preserve the natural taste, scent, and nutrients of fresh apples, all while maintaining product safety and quality. The procedure starts with choosing and assessing premium, mature apples that are devoid of flaws and impurities. The apples are extensively cleaned and scrubbed with chlorinated water or ozone-treated water to eliminate dirt, wax, and pesticide residues. Following the cleaning process, the apples are organized and ground into a smooth pulp with mechanical crushers or mills to dismantle the fruit fibers and free the juice-containing cells. The obtained pulp is treated with pectinase enzymes enzymatically to decompose pectin and enhance juice yield and clarity. The processed pulp is subsequently pressed or extracted with hydraulic or belt presses to isolate the juice from the pomace (solid leftover). The obtained juice is clarified and filtered using centrifugation, decantation, or ultrafiltration to eliminate suspended solids and achieve the intended clarity. To obtain clear apple juice, fining agents such as gelatin or bentonite can be utilized. The clarified juice is subsequently pasteurized at regulated temperatures (approximately 85–95°C) to eliminate microorganisms and inactivate enzymes, thereby prolonging its shelf life without sacrificing taste. In certain situations, the juice undergoes vacuum evaporation to facilitate easier storage and transport. Ultimately, the juice is mixed, standardized, and packed in sterile, airtight containers like glass bottles, PET bottles, or tetra packs, under aseptic conditions. The procedure guarantees that apple juice maintains its unique flavor, scent, and nutritional qualities while adhering to global food safety regulations.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

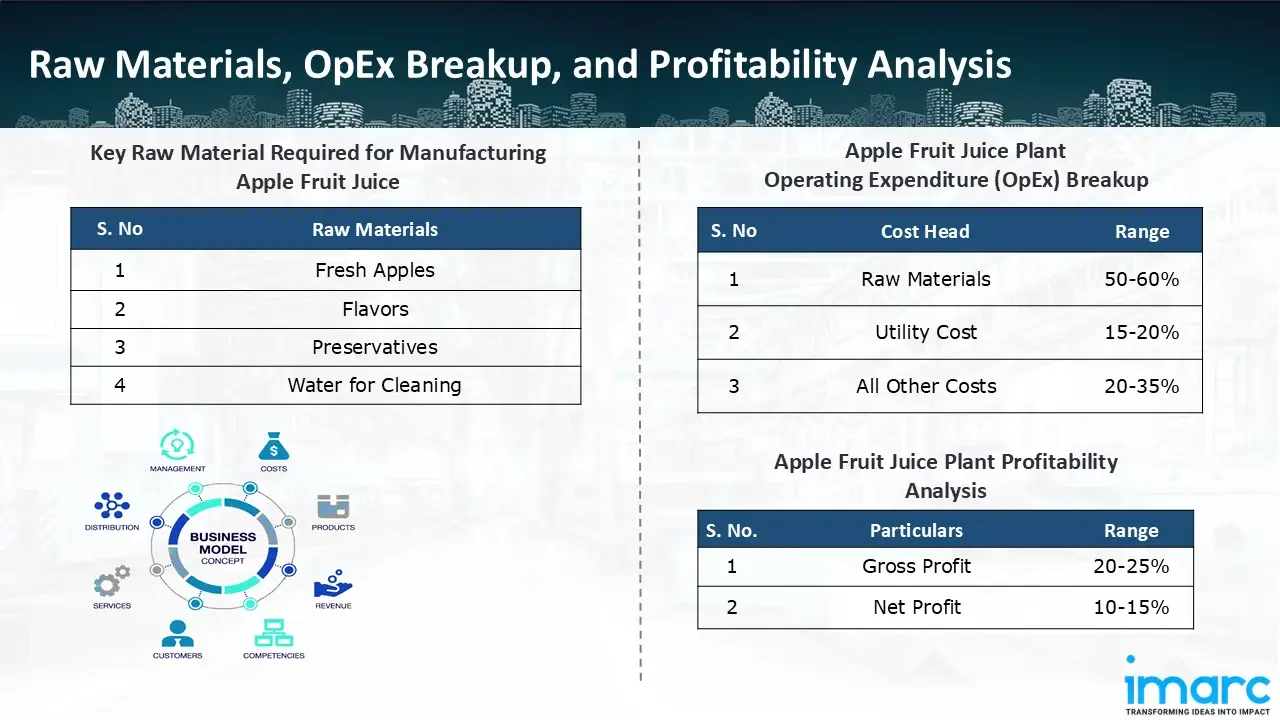

The basic raw materials required for apple fruit juice manufacturing include:

- Fresh Apples

- Flavors

- Preservatives

- Water for Cleaning

Machineries Required:

- Fruit Washer / Drum Washer

- Sorting Conveyor / Grading Machine

- Destoner / De-Stemmer

- Apple Crusher / Hammer Mill / Knife Mill

- Pulper / Mash Tank

- Hydraulic / Screw Press

- Continuous Belt Press / Decanter

- Mash Filter / Rotary Drum Filter

- Centrifugal Separator / Decanter/Fine Clarification

- Diatomaceous Earth Filter / Plate Filter

- Plate Heat Exchanger / Tube Heat Exchanger

- Holding Tank / Pasteurization Tank

- Cooling Unit

- Vacuum Evaporator / Falling Film Evaporator

- Condensing Unit

- Filling Machine (PET/Glass/Tetra Pak)

- Capping / Sealing Machine

- Labeling Machine

- Shrink Wrapping / Carton Packing

- Pumps & Piping

- Storage Tanks

- Refrigeration Unit

- Cleaning In Place (CIP) System

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in an apple fruit juice manufacturing plant ranges between 50-60%, utility cost ranges between 15% to 20%, and all other costs ranges between 20-35% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-25%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the apple fruit juice manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 1,500 tons of apple fruit juice annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In August 2025, Daily Dose, a British cold-pressed juice firm, introduced two new apple juice varieties to Waitrose this week. The new 900ml bottles, which come in Apple & Alphonso Mango and Apple & Root Ginger, are being sold in the chilled juice section at stores.

- In May 2025, Soluna has declared the release of Soluna Apple Juice, a cold-pressed beverage created solely from its famous ANABP 01 apples, which are also known as Bravo apples in Australia.

- In February 2024, the Kroger Racing team and 2023 DAYTONA 500 Champion Ricky Stenhouse Jr. extended their collaboration with Tree Top, a farmer-owned company renowned for its premium fruit-based goods such as apple juices and sauces, for the 2024 NASCAR Cup Series season.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104