Saudi Arabia Precast Concrete Market Trends: Key Drivers Shaping Construction and Infrastructure Growth

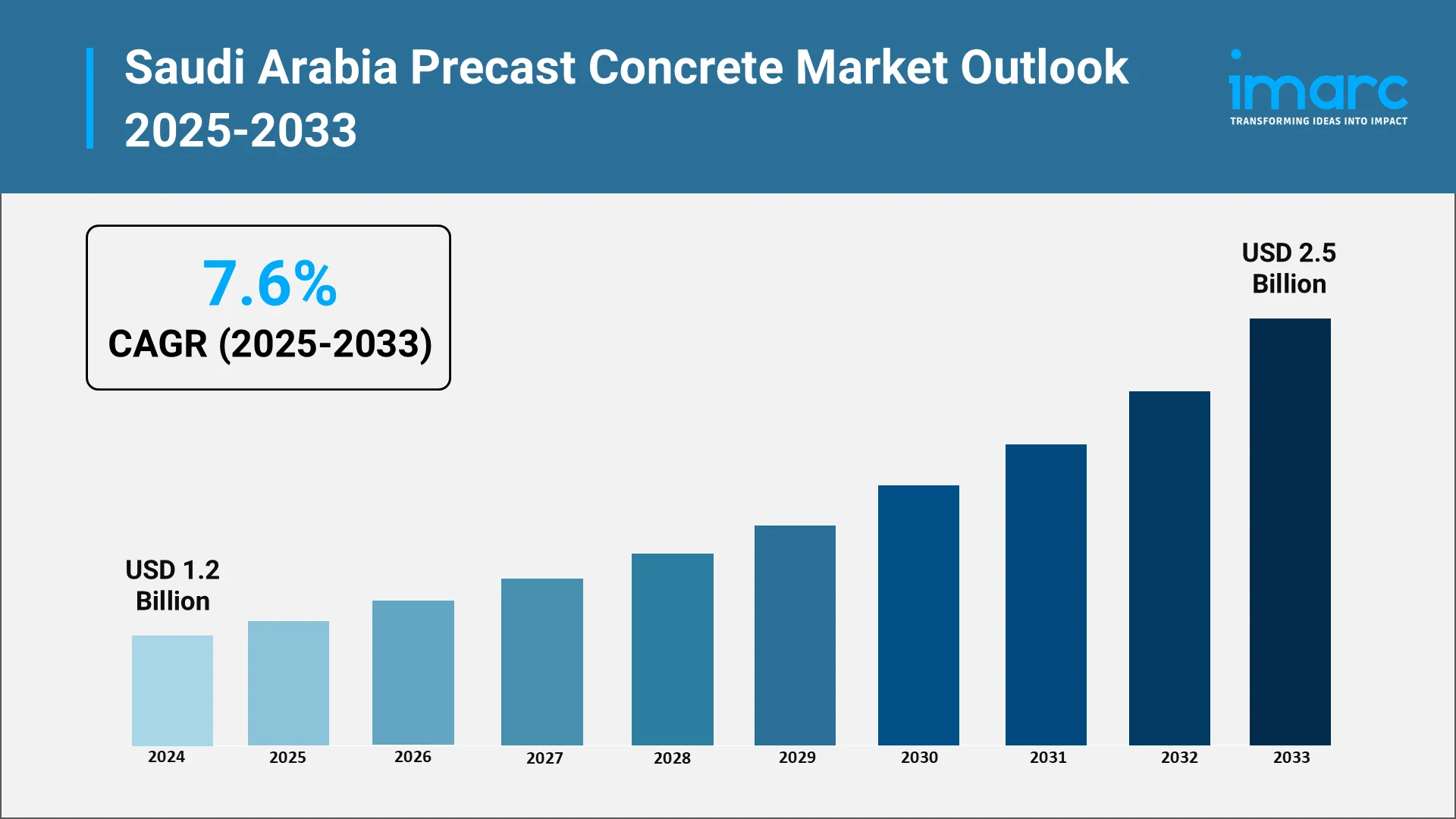

Saudi Arabia’s precast concrete market reached USD 1.2 Billion in 2024 as per the IMARC Group, clear proof that off-site construction is rapidly becoming the Kingdom’s go-to building solution. With residential, commercial, and major infrastructure projects multiplying, developers are increasingly turning to precast building solutions to keep pace. The approach not only boosts efficiency and consistency but also aligns perfectly with the rising quality demands of large-scale housing initiatives and ambitious urban development programs taking shape across the Kingdom.

Vision 2030 is accelerating the shift toward advanced, industrialized building practices by encouraging construction methods that deliver greater speed and efficiency. Megaprojects, economic zones, tourism initiatives, and transport expansions are driving broader use of precast systems, as planners prioritize scalable solutions that enhance structural performance and support long-term national development goals.

Precast systems are becoming essential for meeting tight construction timelines, reducing on-site labor use, and limiting delays in high-volume projects. Controlled factory production improves cost predictability, reduces waste, and enhances durability, making these systems well-suited to Saudi Arabia’s climate conditions. Their technical and operational advantages are strengthening their role across the Kingdom’s construction landscape.

Explore in-depth findings for this market, Request Sample

How Vision 2030 is Transforming the Saudi Arabia Precast Concrete Industry:

Vision 2030 is reshaping Saudi Arabia’s precast concrete industry by encouraging construction toward modern, high-efficiency building methods. The national agenda encourages broader use of factory-produced components to support large housing programs, urban expansion, transport networks, and landmark developments. With megaprojects requiring predictable timelines and consistent quality, precast systems offer an approach that reduces site congestion, limits weather delays, and improves structural reliability. Government-backed initiatives promoting industrialized construction, digital tools, and improved safety standards are strengthening the shift. As developers and contractors adapt to these priorities, precast adoption is rising across residential, commercial, and civil projects, creating a market that is more organized, technologically advanced, and capable of delivering large-scale work at speed.

Building Tomorrow: Trends Reshaping Saudi Arabia’s Precast Concrete Boom

- Rising Adoption of Precast Concrete in Large-Scale Infrastructure Projects

Large-scale infrastructure projects across Saudi Arabia increasingly rely on precast concrete to maintain construction speed, ensure quality, and reduce on-site disruption. Transport networks, bridges, tunnels, and public facilities benefit from standardized components that support predictable scheduling and durable, long-lasting structural performance. This reliance is evidenced by the successful completion of the Riyadh Metro system by Samsung C&T in December 2024, Saudi Arabia's first metro system and part of the world’s largest transit infrastructure project. These developments highlight the growing significance of Saudi precast infrastructure in meeting national development goals.

- Growing Demand from Housing, Urban Development, and Smart City Initiatives

The increasing number of housing programs, expanding urban districts, and smart city plans are accelerating precast adoption due to the need for fast, scalable, and consistent construction. This accelerated large-scale construction is exemplified by Tilal Real Estates’ 2024 launch of the $1.6 billion ‘Heart of Khobar’ smart city project in Saudi Arabia, a massive mixed-use development spanning 268,000 sq m. Precast systems help deliver residential blocks, mixed-use developments, and public amenities while meeting design uniformity, safety standards, and long-term maintenance goals.

- Expansion of Industrial and Logistics Construction Using Precast Systems

The rise of industrial parks, logistics hubs, warehouses, and manufacturing facilities is catalyzing the demand for precast elements to achieve rapid installation and high structural strength. The rapid installation in large-scale logistics and industrial facilities is exemplified by DHL Supply Chain's 2025 announcement of a EUR 130 million (SAR 561.5 million) investment to build a new 78,000 sqm facility regional logistics and distribution hub at Saudi Arabia's Special Integrated Logistics Zone (SILZ) in Riyadh. The facility will serve multiple industries, enhance supply chain efficiency, and support Saudi Arabia’s Vision 2030. These projects benefit from factory-controlled production, steady quality, and reduced downtime, helping support Saudi Arabia’s growing industrial and supply-chain infrastructure.

- Technological Advancements in Modular and Off-Site Manufacturing Processes

Advances in modular construction, automated production lines, and digital design tools are improving precision and helping projects move faster. Off-site manufacturing enhances quality control and supports more complex building requirements, aligning well with Saudi Arabia’s push for modern, technology-focused construction. This approach is also attracting foreign investment, illustrated by the 2024 joint venture between Japan’s Aizawa High Pressure Concrete and Saudi developer Al Saedan to establish a precast factory in Riyadh. The partnership produced pre-stressed concrete components, encouraged the use of digital construction methods, and trained Saudi engineers to build stronger local capability. Precast concrete construction Saudi projects increasingly rely on advanced off-site manufacturing to meet the Kingdom’s growing demand for faster, higher-quality building solutions.

- Shift Toward Sustainable, Energy-Efficient, and Low-Waste Building Materials

As sustainability becomes a national priority, precast concrete is gaining traction for its lower material waste, efficient energy use, and improved lifecycle performance. Controlled production environments reduce environmental impact, while durable components support long-term resource conservation and align with emerging green building standards. This national priority toward sustainability is actively being adopted by local industry leaders, as demonstrated by KPC Precast Company's commitment in 2024 to environmental sustainability by implementing eco-friendly initiatives focused on air quality control, waste management, water conservation, and energy efficiency in its Dammam and Umluj facilities.

Segment-Wise View of the Saudi Precast Concrete Industry:

Breakup by Type

- Floors and roofs represent a key segment, offering strong structural stability and rapid installation for residential, commercial, and industrial projects. Precast slabs reduce construction time and improve overall safety and quality control.

- Columns and beams are widely used for their high load-bearing capacity and consistent manufacturing standards. They support faster framing of buildings and enhance structural reliability across large developments.

- Stairs and landings are preferred for their uniform dimensions, safety compliance, and ease of installation. Their factory-made precision reduces on-site adjustments and speeds up the completion of multi-level structures.

- Walls are popular for providing strong insulation, enhanced durability, and quick assembly. They help developers achieve consistent finishes, improved energy efficiency, and reduced labor requirements on-site.

Breakup by Product

- Structural building components hold a significant market share as they provide the core load-bearing elements needed for residential, commercial, and infrastructure projects. Their factory-controlled production ensures strength, consistency, and faster assembly on-site.

- Architectural building components are gaining traction for facades, wall panels, and decorative features that improve aesthetics while maintaining durability. They allow designers to achieve uniform finishes and complex shapes with reduced on-site work.

- Transportation products are widely used in bridges, tunnels, pavements, and transport corridors. Their high strength, quick installation, and long service life support large infrastructure programs across the kingdom.

- Water and waste handling products like water tanks, culverts, drainage units, and sewage infrastructure offer leak resistance and durable performance. These products help municipalities and industries build reliable utility networks with minimal maintenance needs.

- Others include boundary walls, utility chambers, and modular units tailored for project-specific requirements. Their versatility supports diverse applications across urban development, industrial zones, and public facilities.

Breakup by End Use

- Residential segment is becoming crucial as developers use precast systems to accelerate housing delivery and maintain consistent quality across large-scale projects. Precast elements support faster installation, reduced on-site labor, and improved durability for villas, apartments, and mixed-use residential complexes.

- Non-residential segment benefits from strong demand in commercial buildings, industrial parks, logistics hubs, and institutional facilities. Precast solutions offer speed, cost control, and structural strength, making them suitable for high-volume, performance-driven projects across offices, retail centers, warehouses, and public infrastructure.

Regional Dynamics of Saudi Arabia’s Precast Concrete Market:

The Northern and Central Region shows strong precast adoption driven by government-led infrastructure programs, expanding residential communities, and major developments in Riyadh. Demand is supported by large transport projects, urban renewal efforts, and increasing use of industrialized construction methods to meet rising population and commercial needs.

The Western Region is experiencing growing precast usage influenced by large-scale tourism, hospitality, and mixed-use projects, especially in Jeddah and the Makkah–Madinah corridor. Ongoing airport expansions, waterfront redevelopment, and megaprojects linked to Vision 2030 further boost demand for fast, durable, and high-quality construction solutions.

The Eastern Region relies heavily on precast systems due to the continuous expansion of energy, petrochemical, and industrial facilities. Logistics hubs, worker housing, and commercial developments benefit from reliable, factory-produced components that support rapid installation and withstand the region’s demanding operational environments.

The Southern Region is adopting precast technology, supported by public infrastructure upgrades, growing residential needs, and efforts to improve regional connectivity. Precast elements help address terrain challenges, enhance structural resilience, and deliver consistent quality across projects in developing urban and semi-urban areas.

Forecast (2025–2033):

According to IMARC Group’s projections, the Saudi Arabia precast concrete market is projected to grow at a CAGR of around 7.6% from 2025 to 2033, reaching USD 2.5 Billion by 2033. The growth will be supported by the following factors:

- Increasing for Rapid Build Solutions: Saudi Arabia’s construction sector is prioritizing faster delivery methods as project volumes rise. Precast systems support tight schedules by reducing on-site labor, minimizing delays, and allowing multiple project stages to run in parallel. This approach helps contractors meet demanding timelines for housing, commercial spaces, and public facilities.

- Growing Infrastructure Investments: Government-led investment in transport corridors, utilities, educational facilities, and civic structures is strengthening the precast concrete demand in Saudi. Large programs require dependable building methods that ensure consistency and long service life. Precast elements help meet these expectations while supporting efficient installation across wide geographic areas. This consistent, government-led demand for dependable, high-quality building methods is attracting significant regional investment, as exemplified by the Aamal Company's announcement in 2025 of plans to establish a subsidiary in Saudi Arabia focused on the construction and infrastructure sector, offering services including precast concrete manufacturing.

- Rising Private Sector Participation: Private developers are increasing their role in residential, commercial, and mixed-use projects, driving interest in construction methods that offer predictable costs and faster turnaround. Precast solutions help companies manage complex timelines, control quality, and respond more effectively to market-driven delivery pressures.

- Revitalizing Urban Landscapes: Redevelopment efforts in growing cities are encouraging the use of precast concrete to replace aging structures with minimal disruption. Its quick installation, controlled production, and reliable performance support safe, efficient renewal of dense urban districts, aligning with national goals for modernized and more resilient city environments. This urban renewal effort is bolstered by government initiatives, such as Saudi Arabia's 2025 launch of a Real Estate Stimulus program to boost sector growth and streamline development.

Conclusion:

Saudi Arabia’s construction landscape is undergoing major change as the Kingdom pushes for faster, more efficient, and higher-quality building methods. Precast concrete is gaining strong momentum, supported by large infrastructure programs, expanding housing needs, and major urban redevelopment efforts. Vision 2030 is accelerating the shift toward industrialized construction, digital design tools, and off-site manufacturing, encouraging developers to adopt solutions that shorten timelines and improve consistency. Rising private sector participation, increasing investment in logistics and industrial facilities, and the growing focus on sustainability are further shaping the demand. These developments collectively highlight the key Saudi Arabia precast concrete market trends influencing the future growth.

Building with Confidence: IMARC’s Guide to Succeeding in the Saudi Arabia Precast Concrete Market

IMARC Group supports stakeholders in the Saudi Arabia precast concrete industry with research that clarifies market movements and helps companies navigate evolving construction priorities. Our insights assist clients in identifying growth pockets, managing cost pressures, and strengthening design, production, and project-delivery strategies.

- Market Insights: Highlights demand shifts driven by large-scale infrastructure projects, urban expansion, housing initiatives, and rising interest in durable, faster-to-install building components.

- Strategic Forecasting: Reviews expected gains from industrialized construction, automation in precast manufacturing, and the sector’s alignment with Vision 2030 development goals.

- Competitive Intelligence: Analyzes how leading producers differentiate through quality standards, production capacity, logistics efficiency, and adoption of advanced manufacturing technologies.

- Policy and Regulatory Analysis: Breaks down construction codes, quality certification requirements, sustainability guidelines, and government initiatives influencing precast adoption.

- Tailored Consulting Solutions: Offers guidance on plant expansion, product portfolio development, partnerships, and entry strategies to help companies compete effectively in a growing construction landscape.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104

.webp)