Carbonated Soft Drink Manufacturing Cost Analysis: The Economics of Fizz

What is Carbonated Soft Drink?

Carbonated soft drinks (CSDs) are soft drinks that contain carbon dioxide gas dissolved under pressure, providing the characteristic fizz and invigorating mouth feel that consumers like. They generally consist of carbonated water, sweeteners (sugar, high-fructose corn syrup, or low-calorie alternatives), flavoring ingredients, colorants, and preservatives.

Key Applications Across Industries:

The products that fall under the category are colas, lemon-lime beverages, fruit-flavored sodas, tonic water, and sparkling mineral water. Carbonation not only adds flavor but also extends product life and provides a refreshing, fizzy feel to beverages. The international CSD market is one of the most developed and competitive markets among beverage companies, controlled by multinational players such as The Coca-Cola Company, PepsiCo, and Keurig Dr Pepper. CSDs have been deeply embedded in global popular culture over the decades, linked with recreation, social occasions, and quick-food consumption. But with growing health awareness and shifting consumer behavior, companies are expanding portfolios with sugar-free, low-calorie, and functional versions to maintain their relevance. Flavor innovation, packaging innovation, and marketing innovation, especially among young consumers, are still key drivers in keeping CSDs popular worldwide.

What the Expert Says: Market Overview & Growth Drivers

The global carbonated soft drink market reached a value of USD 440.44 Billion in 2024. According to IMARC Group, the market is projected to reach USD 654.54 Billion by 2033, at a projected CAGR of 4.1% during 2025-2033. The global carbonated soft drink market is underpinned by several drivers such as urbanization, increasing disposable incomes, and lifestyle changes that emphasize convenience and on-the-go usage. Growing food service and fast-food chains throughout emerging markets greatly increase soft drink sales since CSDs continue to be an acceptable pairing beverage.

Product innovation, like the launch of healthier versions (zero-sugar, low-calorie, and fortified sodas), is assisting brands in poaching health-conscious consumers without sacrificing taste. Brand loyalty and aggressive marketing efforts by market leaders through digital communications, celebrity promotions, and sponsorship of sports events also drive strong consumer interaction. Additionally, technological innovation in packaging (sustainable bottles and recyclable cans) and distribution infrastructure development in emerging markets help create greater market accessibility. Seasonal demand peaks, especially in warmer climates, further driving sales. The development of functional and flavored sparkling drinks, such as prebiotic and energy-enriched sodas, presents a new growth horizon. Last but not the least, increasing consumption in Asia-Pacific, Latin America, and Africa driven by high-speed retail penetration and young demographics keeps the world CSD market in steady growth despite health-associated issues.

Case Study on Cost Model of Carbonated Soft Drink Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale carbonated soft drink manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed carbonated soft drink manufacturing plant in India. This plant is designed to manufacture 90 bottles of carbonated soft drink per minute.

Manufacturing Process: The process of producing carbonated soft drinks (CSDs) includes a sequence of well-controlled steps aimed at providing consistency, quality, and safety in each bottle or can that is being manufactured. The procedure commences with water purification since water is the main ingredient that comprises more than 90% of the drink. It is softened, sterilized, and filtered to eliminate contaminants, chlorine, and microbes. The subsequent process is syrup manufacture, during which sweeteners (e.g., sugar, corn syrup, or artificial sweeteners), flavoring materials, colorants, acids (e.g., citric or phosphoric acid), and preservatives are mixed in certain strengths to produce the beverage base or "soft drink concentrate." The syrup is then mixed very carefully in massive stainless-steel vessels under sanitary conditions to attain homogeneity.

When the syrup has been made, it is blended with carbonated water, which has been created by dissolving carbon dioxide (CO2) under pressure into cold water. Cooling is important since CO2 dissolves better at lower temperatures. Carbonation gives the familiar fizz, tang, and cool mouthfeel of soft drinks. After carbonation, the product undergoes filling and packaging, where it is dispensed into bottles or cans using automated systems that maintain pressure to prevent gas loss. The containers are sealed, labeled, and date-coded before being packed for distribution.

Lastly, quality testing and control are carried out at every stage to guarantee taste, level of carbonation, sweetness, and acidity conform to rigorous product standards. This rigorous process allows manufacturers to make CSDs that are consistent, safe, and consumer-friendly globally.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

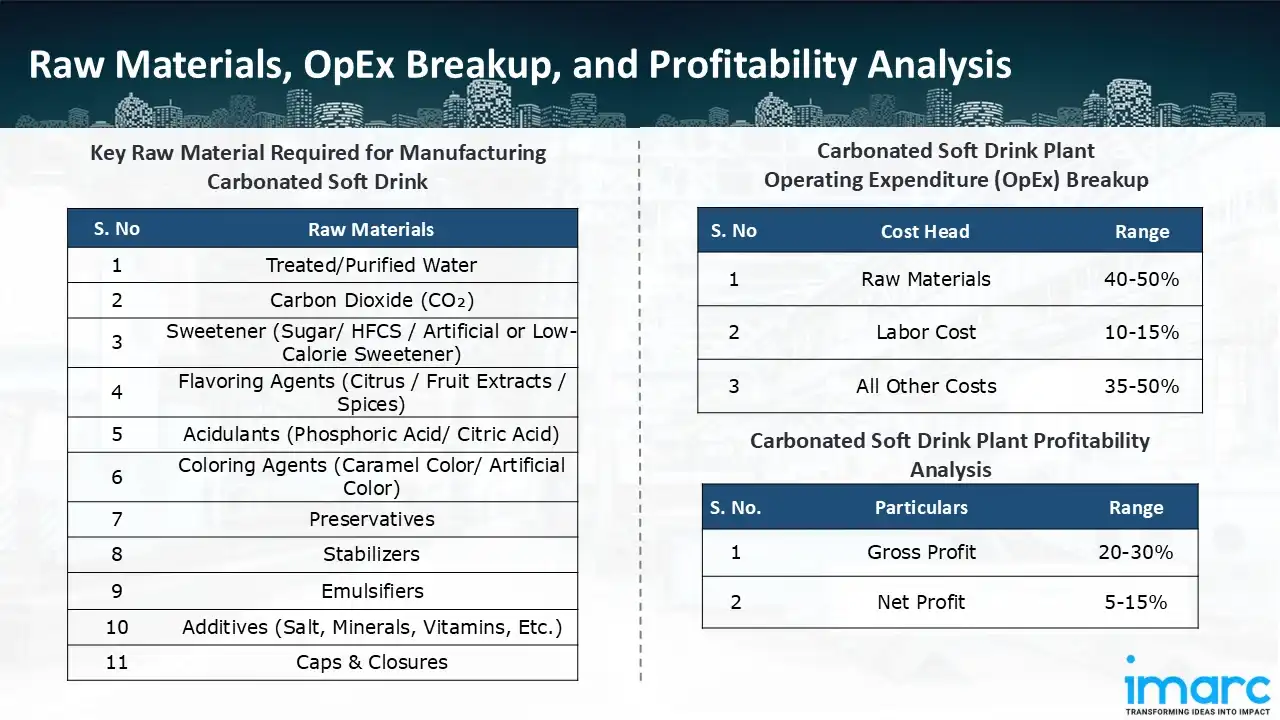

The basic raw materials required for carbonated soft drink manufacturing include:

- Treated/Purified Water

- Carbon Dioxide (CO2)

- Sweetener (Sugar/ HFCS / Artificial or Low-Calorie Sweetener)

- Flavoring Agents (Citrus / Fruit Extracts / Spices)

- Acidulants (Phosphoric Acid/ Citric Acid)

- Coloring Agents (Caramel Color/ Artificial Color)

- Preservatives

- Stabilizers

- Emulsifiers

- Additives (Salt, Minerals, Vitamins, Etc.)

- Caps & Closures

Machineries Required:

- Raw Water Suction / Intake System

- Multimedia / Sand Filter

- Activated Carbon Filter

- Water Softener (Ion-Exchange)

- Reverse Osmosis (Ro) System

- UV Sterilizer / Ozone Generator

- Cip Plant (Clean-In-Place)

- Utilities (3-Phase Supply, Compressed Air, Chilled Water, Steam/Hot Water, CO2 Storage)

- Sugar Melting / Syrup Dissolving Tank

- Syrup Preparation Tank with High-Shear Mixer

- Syrup Filtration Skid

- Dosing Pumps

- Proportioner / Vacuum Blender / Mass Blender

- Holding & Surge Tanks

- Plate Heat Exchanger / Tubular Heat Exchanger

- Inline Blending with Static Mixer Carbonator / Tank Carbonator with Gas/Liquid Contactor / Vacuum Carbonation with Diffusion Stone Systems

- Co2 Booster and Gas Handling Equipment

- Filling & Capping Machine

- Bottle Rinser / Pre-Cleaner

- Counter-Pressure Filler

- Capping Machine / Crown Capper / Screw Capper

- Can Seamers

- Hot-Fill / Pasteurization Before Sealing

- Labelling, Sleeving, Coding & Secondary Packaging

- Shrink Tunnel

- Date Coder / Inkjet Printer / Laser Coder

- Carton Erector / Case Packer / Palletizer

- Quality Control Equipment (In-Line & Lab)

- In-Line Co2 Analyzer & Headspace Monitor

- Brix Refractometer (In-Line / Handheld)

- Ph Meter

- Dissolved Oxygen (Do) Meter

- Microbiological Lab Equipment

- Rheometer / Viscosity Meter

- Support & Automation

- PLC + HMI Control System

- Scada / Data Logging

- Conveyors, Star Wheels, Accumulation Tables

- Sanitation, Safety, Maintenance Planning and Spare Systems

- Pressure Relief Valves

- Rupture Discs

- Gas Detectors for CO2

- Emergency Stops

- Machine Guarding

- Seals & Gaskets

- Diaphragm Pump Parts

- Filters and Membranes (Ro)

- Nozzle/Filler Valve Sets

- Bearings for Motors

- Plc Modules

- Chiller Spare Parts

- Heating Elements

- Daily Visual

- Weekly Lubrication/Filters

- Monthly Calibration (Flow, CO2)

- Quarterly Membrane Checks

- Annual Shutdown for Deep Clean/Inspection

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a carbonated soft drink manufacturing plant ranges between 40-50%, labor cost ranges between 10% to 15%, and all other costs ranges between 35-50% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-30%, and net profit lie between the range of 5-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the carbonated soft drink manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 90 bottles of carbonated soft drink per minute, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, Keurig Dr. Pepper will now manage its own soda distribution, severing its relationship with Reyes Coca-Cola Bottling, after a Texas court order. Dr Pepper will now be replaced by Mr. Pibb, Coca-Cola's intensely flavoured, refreshing, spicy cherry alternative, in numerous Coke-affiliated eateries and theatres.

- In March 2025, PepsiCo will purchase the prebiotic soda brand Poppi for US$ 1.95 billion, which is a significant achievement for a company that was established less than ten years ago.

- In June 2024, Coca-Cola Bottling Company United, Inc. (UNITED) held a ceremony to mark the opening of its new facility in the Kingston neighbourhood of Birmingham. This US$ 330 million investment is anticipated to keep more than 750 jobs in the Magic City and generate up to 50 new jobs.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104