How Big Will the Europe 3D Printing Market Be by 2033? Comprehensive Analysis of Growth and Innovation

The Europe 3D printing market stands at the forefront of a manufacturing revolution that is reshaping industries across the continent. As additive manufacturing technologies mature and expand beyond prototyping into full-scale production, European manufacturers, healthcare providers, and aerospace companies are increasingly embracing these transformative solutions. With substantial government backing, strategic industry collaborations, and breakthrough material innovations, the European 3D printing landscape is positioned for remarkable expansion through 2033.

Explore in-depth findings for this market, Request Sample

Overview of the European 3D Printing Industry:

The Europe 3D printing market has emerged as a pivotal force in the global additive manufacturing ecosystem. The region's sophisticated manufacturing infrastructure, coupled with strong research institutions and favorable regulatory frameworks, has created an environment where industrial 3D printing trends flourish. European manufacturers recognize that additive manufacturing offers unprecedented design freedom, material efficiency, and the ability to produce complex geometries impossible with conventional methods.

The European 3D printing market shows strong momentum across sectors. Automotive manufacturers use additive manufacturing for wind-tunnel models, lightweight seat frames, and on-demand tooling. Aerospace companies adopt it for titanium components that reduce assembly time and fuel use, while healthcare applies it for surgical guides and custom implants.

Market Size Forecast and Revenue Projections by 2033:

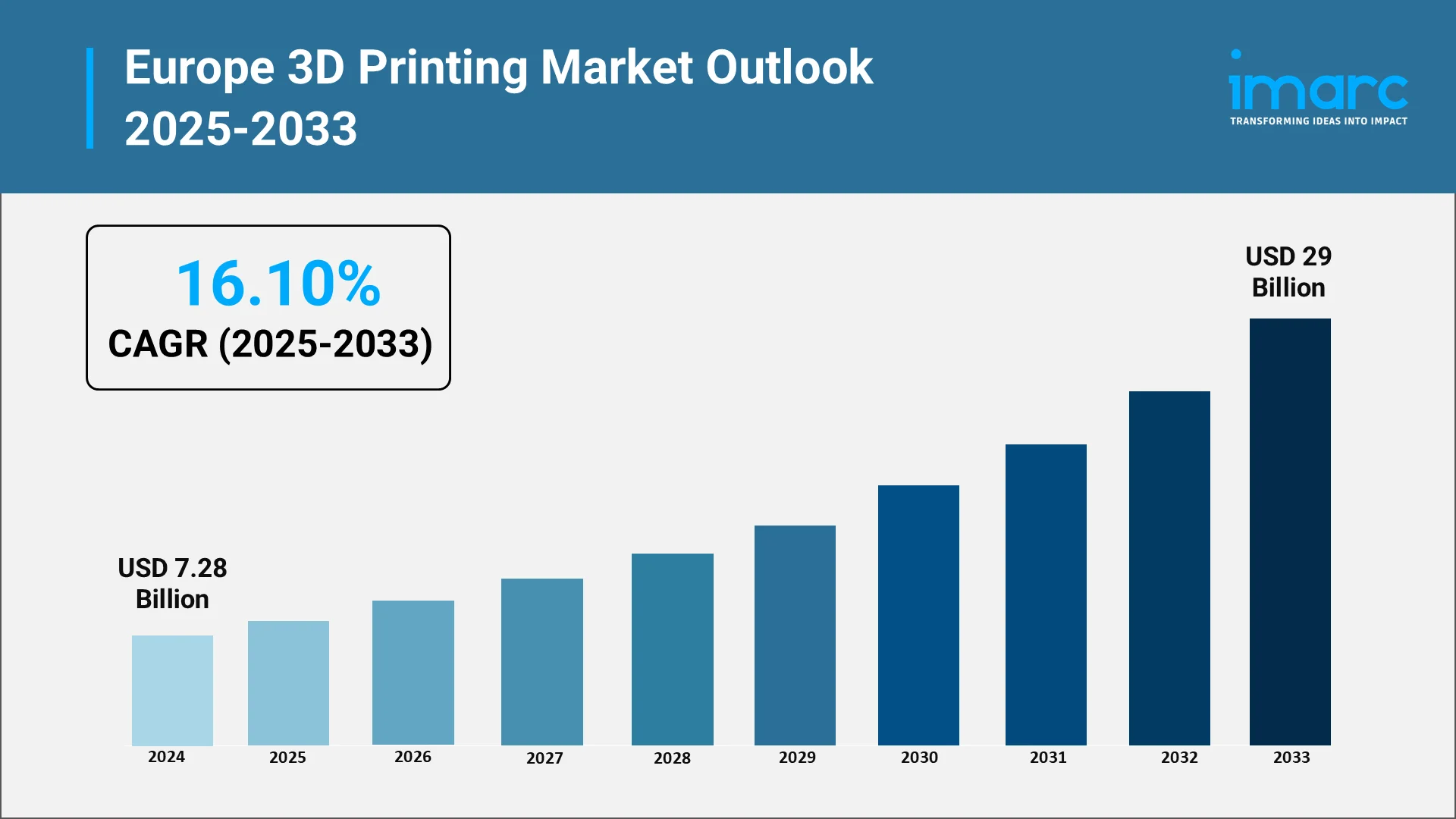

Multiple authoritative market analyses converge on projections indicating substantial expansion for the Europe 3D printing market through 2033. As per IMARC projections, the European 3D printing market was valued at approximately USD 7.28 Billion in 2024 and is expected to grow USD 29 Billion by 2033, representing a CAGR of 16.10 % during the forecast period from 2025 to 2033.

These projections reflect accelerating adoption across diverse industries and the maturation of additive manufacturing technologies from prototyping tools to production-ready solutions. The growth trajectory demonstrates increasing confidence among European manufacturers in the reliability, scalability, and economic viability of 3D printing for serial production applications. Also, industries such as aerospace and healthcare rely heavily on specialized services to streamline production processes without requiring substantial upfront capital investments in equipment.

Key Growth Drivers and Industry Catalysts:

Several fundamental factors propel the Europe 3D printing market expansion. Understanding these catalysts provides insight into the sustained momentum anticipated through 2033.

- Government Investment and Policy Support

Government initiatives play a pivotal role in shaping the Europe 3D printing market’s growth trajectory toward 2033. The European Union and national programs like Horizon Europe and France 2030 are driving large-scale funding and policy support for additive manufacturing research and commercialization. Also, in October 2024 the UK government announced a £4.3 Billion investment in advanced manufacturing, including 3D printing initiatives, to boost innovation, sustainability, and industrial competitiveness under its long-term industrial strategy. These initiatives foster innovation and accelerate industrial adoption through grants and collaborative R&D platforms. By enhancing infrastructure and supporting advanced manufacturing capabilities, such programs reinforce Europe’s leadership in industrial 3D printing trends, positioning the region for sustained technological competitiveness.

- Material Science Advancements

Material innovation remains central to the Europe 3D printing market’s projected growth by 2033. Advanced polymers, metals, and composites are enabling new applications across sectors such as automotive, aerospace, and healthcare. For instance, halogen-free flame-retardant polymers and next-generation metal powders enhance performance, recyclability, and environmental compliance. Also, the EU launched the MADE-3D project, coordinated by Universität Paderborn (Germany), to advance multi-material additive manufacturing, promoting material science innovation and lightweight component production across Europe’s 3D printing sector. Collaborations between additive manufacturing companies and metallurgical experts drive breakthroughs in material durability and cost efficiency. As industrial 3D printing trends evolve, these material advancements expand the range of viable applications, improve sustainability, and strengthen Europe’s position in high-value manufacturing segments, particularly 3D printing in automotive.

- Cost Reduction and Operational Efficiency

Cost efficiency is a key factor accelerating the Europe 3D printing market’s expansion through 2033. Advanced software, automation, and workflow optimization tools now reduce build costs by up to 20% and boost printer utilization rates. These improvements make additive manufacturing increasingly competitive with conventional production methods, particularly in automotive and industrial sectors. Automated build preparation and digital manufacturing workflows minimize manual intervention, lower error rates, and streamline production cycles. Such operational efficiencies, combined with reduced material waste, reinforce industrial 3D printing trends driving adoption across European manufacturing, ensuring scalability and profitability for both prototyping and serial production.

- Customization Demands and Rapid Prototyping Needs

Rising demand for product personalization and rapid prototyping continues to fuel Europe’s 3D printing market growth. Additive manufacturing perfectly aligns with customization requirements across healthcare, consumer goods, and automotive sectors. Medical implants, for example, achieve superior patient-specific outcomes, while automotive companies use 3D printing for custom components and design testing. This flexibility enhances product innovation speed and market responsiveness. As industrial 3D printing trends shift toward mass customization, European manufacturers increasingly leverage the technology to reduce lead times, optimize design precision, and meet evolving consumer and industry-specific needs by 2033.

Adoption Across Manufacturing Sectors:

The Europe 3D printing market demonstrates broadening adoption across multiple industrial sectors, each leveraging additive manufacturing for distinct competitive advantages.

- Automotive Sector Leadership

The automotive industry remains at the forefront of Europe’s 3D printing adoption, driving innovation through rapid prototyping, lightweight component production, and on-demand tooling. Major manufacturers increasingly integrate additive manufacturing to enhance design flexibility, reduce waste, and accelerate time-to-market. In March 2025, Bosch inaugurated a €6 Million metal additive manufacturing facility in Germany to enhance automotive component production efficiency, showcasing Europe’s leadership in advanced 3D printing in automotive. As industrial 3D printing trends evolve, automotive players are leveraging digital production ecosystems to achieve cost-efficient customization and sustainable manufacturing, positioning the sector as a major contributor to the projected expansion of the Europe 3D printing market by 2033.

- Healthcare and Medical Applications

Healthcare is emerging as one of the fastest-growing segments in the Europe 3D printing market, driven by rising demand for patient-specific medical devices and implants. Additive manufacturing enables high-precision production of surgical models, prosthetics, and biocompatible implants tailored to individual anatomy. With continuous advancements in material science and regulatory support, 3D printing in healthcare is transforming clinical outcomes and reducing procedural costs, reinforcing the sector’s pivotal role in shaping industrial 3D printing trends through 2033.

- Aerospace and Defense Applications

The aerospace and defense industries are accelerating 3D printing adoption to improve efficiency and performance. Additive manufacturing allows for lightweight, complex, and consolidated parts that enhance fuel efficiency and reduce assembly time. European aerospace firms increasingly employ 3D printing in metal and composite materials for critical components, lowering production costs and maintenance downtime. As these industries expand their reliance on digital fabrication, they significantly influence industrial 3D printing trends, strengthening Europe’s global competitiveness by 2033.

- Construction and Infrastructure

Additive manufacturing is revolutionizing Europe’s construction and infrastructure sectors by enabling faster, more sustainable, and cost-effective building processes. 3D printing technologies are being applied to fabricate complex architectural structures, prefabricated components, and eco-friendly materials, reducing labor intensity and material waste. Governments and developers are adopting these solutions to meet sustainability targets and urbanization demands. As industrial 3D printing trends continue to advance, construction applications are expected to play a crucial role in expanding Europe’s market size by 2033.

- Energy Sector Applications

The energy sector is leveraging 3D printing to optimize component design, streamline maintenance, and enhance efficiency in power generation systems. From producing turbine parts to developing customized repair solutions, additive manufacturing supports operational resilience and cost reduction. As renewable energy adoption grows, 3D printing enables lightweight, high-performance components that improve energy efficiency. These advancements underscore the sector’s contribution to industrial 3D printing trends, positioning energy applications as a vital growth driver in Europe’s market by 2033.

Regional Insights and Innovation Hubs:

Geographic distribution within the Europe 3D printing market reveals distinct regional strengths and innovation centers.

- Germany: Germany remains a key hub in the Europe 3D printing market, driven by its advanced manufacturing infrastructure and strong R&D ecosystem. Collaboration between universities and industries continues to enhance multi-material and metal additive manufacturing. These developments support lightweight automotive components and align with industrial 3D printing trends shaping Europe’s technological evolution through 2033.

- France: France is emerging as one of the fastest-growing regions in the Europe 3D printing market, supported by digital transformation and sustainability initiatives. Aerospace leader Safran utilizes additive manufacturing for lightweight aircraft parts, while the “La French Tech” program fosters innovation and startup growth in advanced manufacturing and 3D printing for automotive and industrial applications.

- United Kingdom: The United Kingdom is reinforcing its role in the Europe 3D printing market through renewed participation in Horizon Europe. Access to EU research networks enables UK innovators to expand material research, process automation, and scalable production. These initiatives enhance competitiveness across automotive, aerospace, and healthcare sectors while supporting evolving industrial 3D printing trends.

- Italy: Italy continues to advance its presence in the Europe 3D printing market through strategic partnerships and technology adoption centers. Initiatives such as the Metal Jet Adoption Center drive process optimization and application development. These advancements enable cost-effective manufacturing solutions, supporting industries like automotive and aerospace while contributing to broader industrial 3D printing adoption.

- Spain: Spain is strengthening its role in the Europe 3D printing market by leveraging regional collaborations and EU-backed initiatives. Programs like SIRAMM promote knowledge exchange and additive manufacturing excellence across countries. These efforts enhance innovation capacity, workforce skills, and the adoption of 3D printing in automotive, aerospace, and industrial applications across Europe.

Competitive Outlook and Future Opportunities:

The Europe 3D printing market is driven by leading companies like HP Inc., Stratasys Ltd., EOS GmbH, 3D Systems, and Materialise NV. These firms dominate through R&D investments, product innovation, and AI-driven manufacturing solutions. Their collaboration across polymers, metals, and software enhances industrial efficiency and accelerates 3D printing in automotive and aerospace sectors. As industrial 3D printing trends evolve, these companies continue expanding Europe’s leadership in digital manufacturing and sustainable production.

Future Opportunities:

- Software Innovation and Digital Integration: Software advancements are reshaping the Europe 3D Printing Market, streamlining production from design to delivery. AI-powered platforms enhance build accuracy, reduce costs, and improve quality control. Integration with CAD/CAM tools accelerates automation and scalability. As industrial 3D printing trends evolve, these digital innovations boost precision, efficiency, and competitiveness in 3D printing in automotive applications.

- Collaborative Initiatives and Industry Partnerships: Collaborative ventures are accelerating growth in the Europe 3D printing industry. Partnerships like the Leading Minds Consortium unite EOS, Stratasys, and Materialize to advance standardization, innovation, and workforce development. These alliances strengthen cross-sector collaboration, fostering shared expertise and driving Europe’s technological leadership through 2033.

- Talent Development and Workforce Upskilling: Skill development remains vital to the Europe 3D Printing Market’s growth. Europe faces talent shortages, prompting universities to introduce specialized additive manufacturing programs. These initiatives enhance capabilities in 3D printing in automotive and industrial production. As industrial 3D printing trends accelerate, skilled professionals will ensure Europe’s innovation, scalability, and market leadership through 2033.

- Sustainability and Circular Manufacturing: Sustainability is central to the Europe 3D printing industry outlook. Additive manufacturing reduces waste and energy consumption, aligning with circular economy goals. Companies adopt bio-based materials and recyclable systems, supporting eco-friendly production models. In automotive applications, sustainable manufacturing enhances compliance, positioning Europe as a global sustainability leader by 2033.

- Decentralized and On-Demand Manufacturing Models: Decentralized manufacturing is transforming the Europe 3D printing market by enabling localized, flexible, and cost-efficient production. Service bureaus empower SMEs to adopt additive manufacturing without heavy investment. Supporting industrial 3D printing trends, these models strengthen 3D printing in automotive supply chains, reduce dependencies, and drive Europe’s shift toward sustainable, distributed production ecosystems by 2033.

Conclusion: Navigating the Future of European Additive Manufacturing

The Europe 3D printing market is advancing rapidly, driven by technological progress, expanding applications, and alignment with regional manufacturing goals. Strong growth across services and software highlights the sector’s maturity, supported by government programs and material innovations enhancing cost efficiency. Healthcare and aerospace lead adoption, while automotive maintains steady use. Regional strengths in Germany, France, and the UK foster innovation, with Eastern Europe expanding capabilities. Collaboration, automation, and standardization remain key to unlocking full potential as additive manufacturing drives Europe’s digital and sustainable industrial transformation.

Partner with IMARC Group for Strategic Market Intelligence

The evolving Europe 3D printing market presents both opportunities and complexities requiring sophisticated analysis and strategic planning. IMARC Group delivers the comprehensive market intelligence necessary to navigate this dynamic landscape successfully.

- Data-Driven Market Research: Gain insights into valuations, growth, and innovations in polymers, metals, and ceramics across European additive manufacturing markets.

- Strategic Growth Forecasting: Predict additive manufacturing trends, AI-driven optimization, and sustainability impacts using advanced modeling and expert-based forecasting methods.

- Competitive Benchmarking: Assess competitors, technology roadmaps, and innovations shaping leadership in 3D printing hardware, software, and material advancements through 2033.

- Policy and Infrastructure Advisory: Understand European funding, regulations, and standards influencing additive manufacturing adoption, certifications, and quality assurance processes.

- Custom Reports and Consulting: Obtain tailored research and strategic guidance for investments, market expansion, and technology adoption in Europe’s 3D printing sector.

At IMARC Group, we empower manufacturing and technology leaders with insights to seize Europe’s additive manufacturing opportunities, driving informed decisions and sustainable competitive growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104

.webp)