Sewage Treatment Plant Cost Model: From Wastewater to Resource Recovery

_11zon.webp)

What is Sewage Treatment?

Treatment of sewage is the procedure of eliminating contaminants from domestic or industrial wastewater to yield treated effluent that can be safely released into the environment or recycled for different purposes. Sewage contains organic matter, nutrients, suspended solids, microorganisms, and chemical pollutants and hence physical, chemical, and biological processes must be utilized for purification.

Key Applications Across Industries:

Treated sewage has some key characteristics of low biochemical oxygen demand (BOD), low suspended solids, and pathogen content minimized. Sewage treatment plants (STPs) consist of primary, secondary, and tertiary treatment units, where pollutant removal efficiency is increased in each stage. Uses include safe disposal of effluent, reuse in agriculture and landscaping, and recycling for industrial cooling purposes or construction work. The key benefits of sewage treatment include safeguarding public health, averting waterborne diseases, water resource conservation, and meeting environmental standards. From an economic perspective, STPs facilitate sustainable urbanization through enabling circular water management and minimizing dependence on freshwater. In the future, sewage treatment will be a key driver in smart city planning, climate-resilient urban planning, and industrial water reuse, thus paving the way for a sustainable future.

What the Expert Says: Market Overview & Growth Drivers

The India wastewater market size reached USD 9.64 Billion in 2024. According to IMARC Group, the market is projected to reach USD 18.63 Billion by 2033, at a projected CAGR of 7.6% during 2025-2033.

The sewage treatment industry is fueled by several long-standing demand drivers. First, urbanization and population expansion are driving sewage volumes higher at an accelerating rate, filling the need for constant new treatment plants. Second, strict environmental laws across the globe require municipalities and industries to treat wastewater prior to discharge. Third, expanding water scarcity is pushing implementation of wastewater reuse for agricultural, landscaping, and industrial uses. Fourthly, increased awareness regarding public health and sanitation through government initiatives such as India's Swachh Bharat Mission or UN Sustainable Development Goals is encouraging mass-scale deployment of STPs. Future trends in the next five years involve integration of decentralized treatment plants to serve local communities, implementation of membrane bioreactors (MBR) and moving bed biofilm reactors (MBBR), and digital monitoring platforms for real-time water quality management. Competitive strengths are water resource recovery and energy-efficient technologies, but competitive weaknesses are high capital and operating expenses, management of sludge, and requirement for skilled manpower. From the sustainability viewpoint, STPs play an important role in limiting environmental contamination and allowing water recycling. Industry reaction comprises public-private partnerships, use of renewable-powered plants, and advancements in low-energy treatment technologies to offset cost minimization against environmental regulation.

Case Study on Cost Model of Sewage Treatment Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium-scale sewage treatment plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed sewage treatment plant in India. This plant is designed to treat 60 million litre of sewage per day.

Treatment Process: The wastewater treatment process starts with the raw sewage inlet chamber, to which wastewater is pumped into the plant, then through a screen and grit chamber to eliminate coarse solids and trash. If available, oils and greases are removed in a special oil and grease trap. The flow is then directed to the equalization tank, which smooths out fluctuation in sewage volume prior to going to the aeration tank. In this phase, microbes proliferate on bio-media and air is provided through diffusers for sustaining dissolved oxygen, oxidizing the organic matter and minimizing BOD and COD. The blended solution then passes to a settling tank, in which sludge precipitates at the tank's base and clarified water overflows into a collection tank, with the sludge subsequently dried in drying beds. The treated water flows into a filter feed tank and is treated at tertiary level through pressure sand filters (PSF) to reduce turbidity and activated carbon filters (ACF) to remove odor, color, and organic content. Disinfection is done in a chlorine contact tank, where sodium hypochlorite is used to destroy pathogens. Lastly, the treated water is gathered in a storage tank for safe disposal or reuse for environmental protection and resource recovery.

_11zon.webp)

Mass Balance and Raw Material Required: The primary raw materials used in the sewage treatment plant are sewage water, sodium hypochlorite, DAP, urea and bacteria bioculture. For a plant treating 1 million litre of sewage, 1.05 million litre of sewage water, and 9.2 kg of sodium hypochlorite, 5.0 kg of DAP, 3.2 kg of urea and 1.5 kg of bacteria bioculture are required.

Machineries Required:

- Moving Bed Bio Reactor (MBBR)

- Diesel Generator

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a Treatment plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

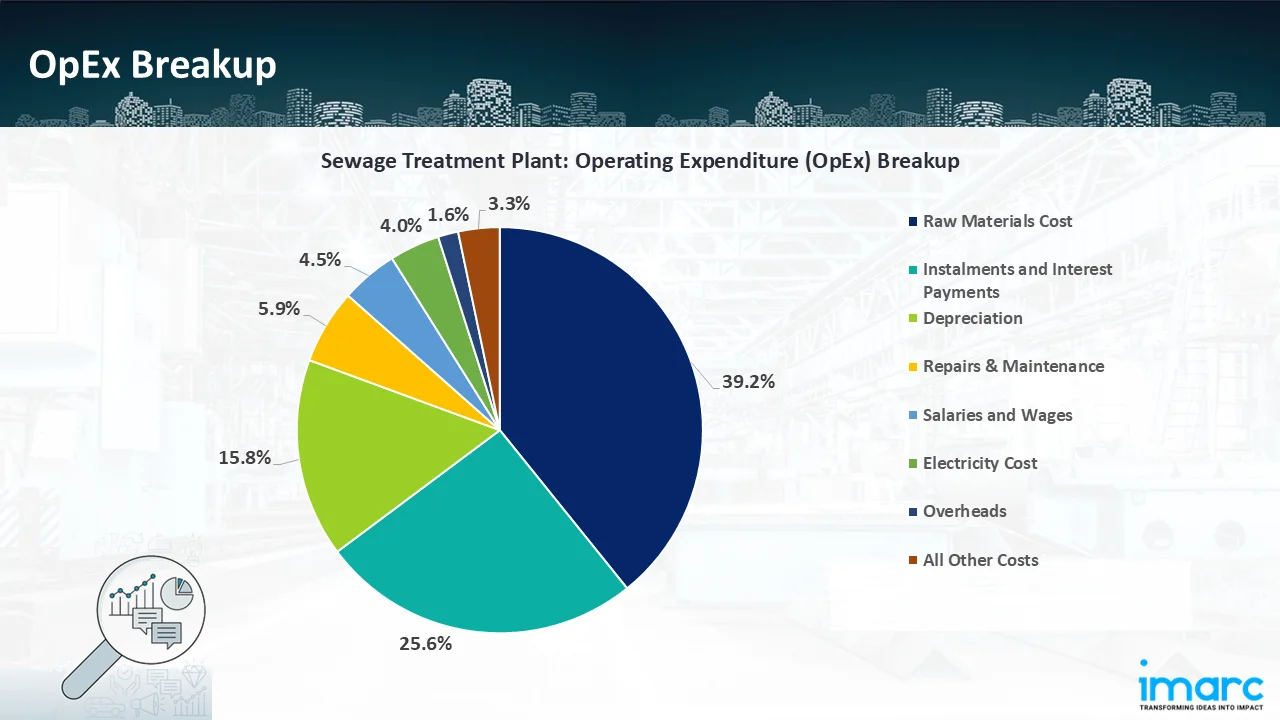

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a Treatment plant effectively. Opex in a Treatment plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a Treatment plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

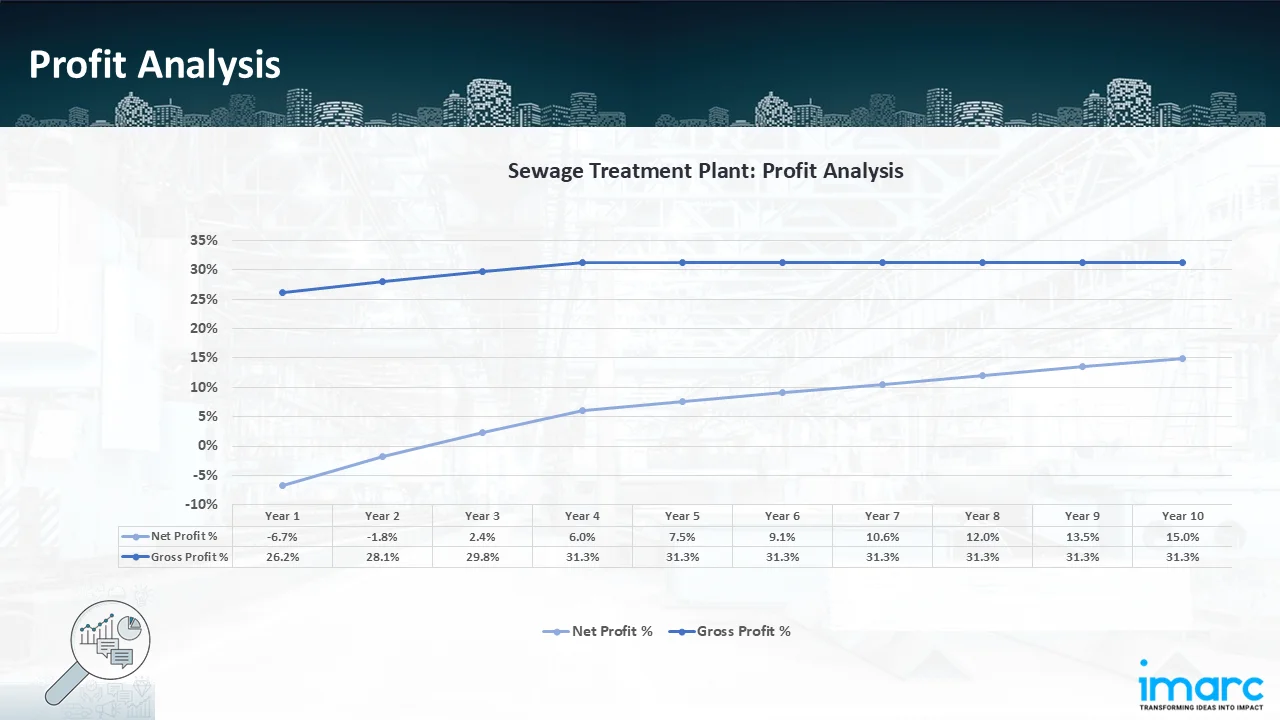

- Profitability Analysis Year on Year Basis: The proposed sewage plant, with a capacity of treating 60 million litres of sewage per day, achieved an impressive revenue of INR 487 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 26.2% to 31.3% by year 10, and net profit rises from a negative of 6.7% to a positive of 15.0%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the sewage treatment plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, Treatment, capital expenditure, and operational expenses. By addressing the specific requirements of treating 60 million liters of sewage per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale Treatment ventures.

Latest News and Developments:

- In June 2025, as part of the Namami Gange project, Prime Minister Narendra Modi officially opened six sewage treatment facilities (STPs), including one in Begusarai and five in Patna district. The regions of Digha and Kankarbagh are home to two significant STPs. While the Kankarbagh plant can treat 50 MLD of wastewater, the Digha facility, which is thought to be the largest STP in the state, can process 100 MLD (million litres per day).

- In June 2025, The Construction Authority for Potable Water and Wastewater (CAPW) in Cairo, Egypt, has chosen ACCIONA, in partnership with the local firm DHCU, to operate and maintain Phase II of the Gabal El Asfar wastewater treatment complex for a period of eight years. The €35 million contract comprises the implementation of numerous improvements and rehabilitation projects on the complex's two facilities, each of which has a daily capacity of 500,000 m³.

- In June 2025, EMS, a water and sewerage infrastructure operator, announced on Monday that it had won the lowest bid (L1) for two projects totalling Rs 202.85 crore that the UP Jal Nigam (Urban) had put out.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the Treatment facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish Treatment facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104