Cashew Nut Processing Cost Analysis: Understanding Cost Drivers and Process Insights

What is Cashew Nut?

The cashew nut is the kidney-shaped seed of the cashew apple, which is the fruit of the tropical evergreen tree Anacardium occidentale. In trade, the "cashew nut" is the edible kernel extracted from the drupe that lies under the cashew apple; the apple itself is consumed for juices and value-added products in certain markets. Cashew trees are adapted to tropical and subtropical regions with good drainage soils, and leading producers are Vietnam, India, Côte d'Ivoire, Brazil, and some West African states.

Key Applications Across Industries:

Raw cashew nut picked is a hard outer shell housing caustic cashew nutshell liquid (CNSL), a premium industrial by-product for use in resins, coatings and friction materials, and edible kernel within. Cashews are labor- and energy-costly to process: they must be dried, dehusked, shelled (thermal or mechanical), peeled, graded, and frequently split (whole, halves), in addition to roasting and ultimate quality segregation. The value chain ranges from smallholder farms through local shelling houses to mid-scale processors and integrated exporters; margins and product quality are largely determined by kernel integrity (whole or broken), moisture management, and post-harvest treatment. Marketing channels involve bulk commodity export, branded retail (value-added flavors, roasted/salted, organic), and ingredient supply into foodservice and confectionery. Due to kernels' high price premium over raw nuts, processing capability and technical competence (to avoid breakage and contamination) are paramount drivers of local value retention and export earnings for producing nations.

What the Expert Says: Market Overview & Growth Drivers

The global cashew nut market reached a value of USD 7.7 Billion in 2024. According to IMARC Group, the market is projected to reach USD 10.7 Billion by 2033, at a projected CAGR of 3.7% during 2025-2033. The global cashew industry is shaped by snack food, confectionery, and ingredient demand trends on the one side and supply-side forces related to production cycles and processing capacity on the other. On the supply side, there are no significant threats, while on the demand side, higher disposable incomes and westernized snacking patterns in Asia, Africa, and Latin America, and health-oriented consumer trends in developed economies, have heightened demand for nuts as protein, perceived-healthy snacks; cashews gain benefit from premium position as a versatile kernel employed in snacks, vegetable dairy alternatives, sauces, and ready meals. Retail and foodservice innovation (flavored cashews, ready-to-eat packs, and plant-based cashew cheeses/creams) further increase demand. Supply drivers are the geographical overlap of raw production and the speed of local processing investment: nations that expand domestic shelling and grading retain more value than raw-kernel exporters. Volatility in prices is driven by weather (droughts, cyclones), pests, and long-term crop cycles, which lead to periodic tightness and premium prices. Policy and infrastructure play a role, export incentives, port efficiency, and availability of mechanized shelling lower costs. Availability of labor and workplace security (handling corrosive CNSL) influence processing feasibility and automation take-up. Lastly, pressures of sustainability and traceability (deforestation threat, farmers' incomes, and child-labor attention) are influencing buying: large customers increasingly require traced, certified supply chains, setting which source areas secure long-term contracts. Collectively, demand from consumers, processing capability, climatic risk and ESG requirements dictate cashew market direction and where investment provides most commercial value.

Case Study on Cost Model of Cashew Nut Processing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale cashew nut processing plant. We developed a comprehensive financial model for the setup and operation of a proposed cashew nut processing plant in India. This plant is designed to process 300 tons of cashew nut annually.

IMARC Approach: Comprehensive Financial Feasibility

Processing Flow: Cashew nut processing is a multi-step activity aimed at transforming raw cashew nuts (RCNs) into consumable kernels for consumption and export. Processing starts with drying and cleaning, where recent cashew nuts are sun-dried for a period of several days to dry up to a moisture level of about 8–10%, inhibiting mold formation and ease of shell removal. The second process is roasting or steaming, which breaks down the tough outer shell and loosens the inner kernel of cashew. In traditional production, nuts are roasted in oil or hot air, but in modern facilities, steam cooking is used to gain better control and safety. Then, shelling is done by hand or through mechanical shellers to detach the outer shell from the kernel, a process that is gentle because breakage lowers the nut's market value. The shells that are stripped away are in turn recovered to harvest cashew nutshell liquid (CNSL), a costly industrial by-product in the production of resins, paints, and brake linings.

After shelling, kernels are re-dried in hot air chambers to render the thin inner skin (testa) brittle so that it can be peeled easily. Peeling may be manual or by pneumatic machines. The peeled kernels are graded and separated according to size, color, and quality into different commercial grades, whole, splits, broken, etc. Last of all, the kernels are inspected for quality, packaged, and vacuum sealed to avoid moisture absorption and rancidification. Value addition processes like roasting, salting, or flavouring are usually done for products to be sold in retail. During the process, hygiene maintenance, temperature control, and kernel breakage prevention are important to attain premium export-grade quality and profitability.

Get a Tailored Feasibility Report for Your Project Request Sample

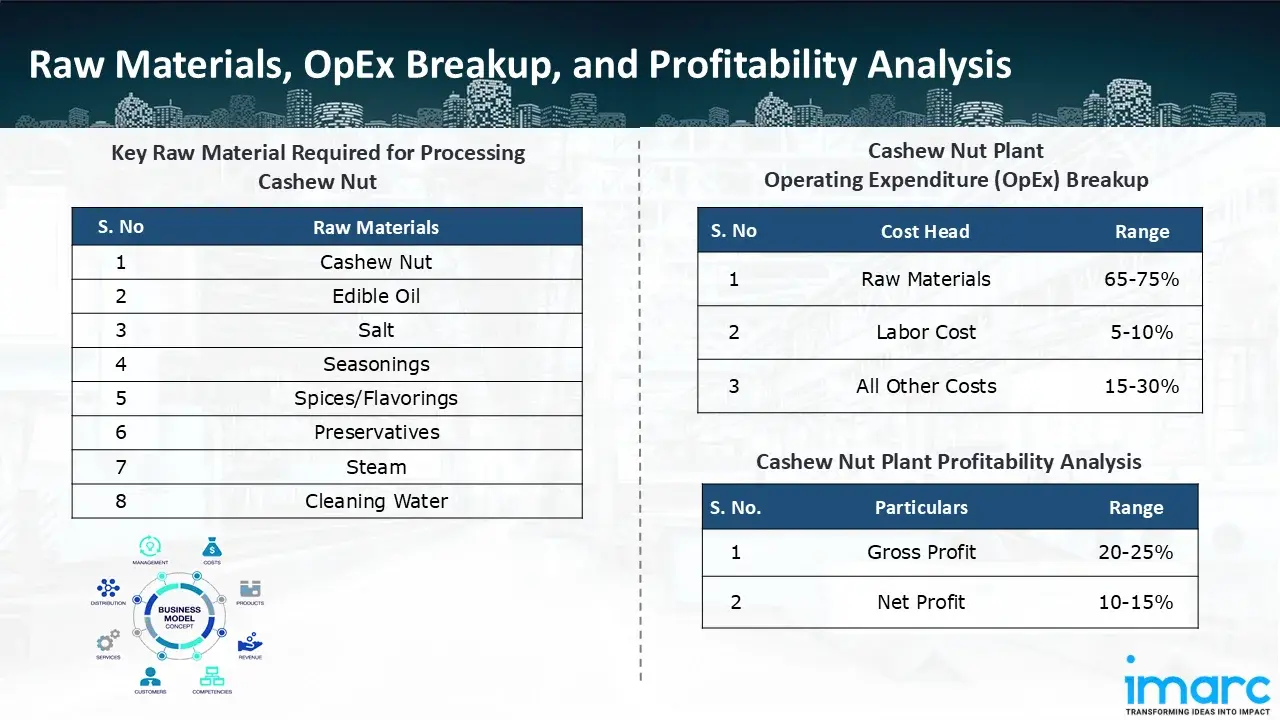

Raw Material Required:

The basic raw materials required for cashew nut processing include:

- Cashew Nut

- Edible Oil

- Salt

- Seasonings

- Spices/Flavorings

- Preservatives

- Steam

- Cleaning Water

Machineries Required:

- Seed Cleaner / Pre-Cleaner

- Magnetic Separator

- Gravity Separator

- Steam Boiler / Steamer

- Roasting Oven / Drum Roaster

- Cashew Nut Shelling Machine

- Manual Shelling Tools

- Tray Dryer / Fluidized Bed Dryer

- Cashew Peeling Machine

- Size Grader / Cashew Grader

- Color Sorter

- Metal Detector

- Vacuum Packaging Machine / Sealer

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a processing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a processing plant effectively. Opex in a processing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a processing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a cashew nut processing plant ranges between 65-75%, labor cost ranges between 5% to 10%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-25%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the cashew nut processing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, processing, capital expenditure, and operational expenses. By addressing the specific requirements of processing 300 tons of cashew nut annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale processing ventures.

Latest News and Developments:

- In January 2025, Minister of Trade and Industry, opened a cutting-edge cashew processing plant at Attinguié, Côte d'Ivoire. The plant, which can process 45,000 tonnes of cashew nuts a year, was constructed by Singapore-based Valency International for 24 billion CFA francs (USD 15.8 million).

- In October 2024, the Minister of Agriculture is scheduled to open a 3.5bn/- cashew nut processing facility at Mmovo Village, Newala District, Mtwara Region. The Tandahimba-Newala Cooperative Union (TANECU) built the new facility, which can process 3,500 tonnes of cashew nuts annually.

- In July 2024, the prime minister of Côte d'Ivoire officially opened a new cashew nut processing facility in Boundiali, Côte d'Ivoire, worth 15 billion CFA francs (USD 24.9 million). This 10-hectare plant is located in the communal hamlet of Tombougou-Samorosso and is funded by the Emirati business Pan African Agro Commodities (PAAC).

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104