Mobile Accessories Manufacturing Cost Analysis: Plugged Into Profitability

What are Mobile Accessories?

Mobile accessories encompass a wide range of auxiliary products that are intended to complement, protect, enhance, or extend the functional capabilities of smartphones and other portable communication devices. Examples of these accessories include protective cases, screen guards, chargers, power banks, earphones, wireless earbuds, smart wearables, mounts, portable speakers, and connectivity adapters. They enable better usability, device safety, personalization, convenience, and integration with digital ecosystems. Mobile accessories are made from a variety of materials and technologies to meet various performance, durability, and design requirements for different groups of users. This category is ever-growing as new trends in hardware and usage patterns develop around the world.

Key Applications Across Industries:

Mobile phone accessories also have a wide range of practical, protective, aesthetic, and functional uses within both consumer and professional environments. Their primary uses are for the protection of devices themselves; cases, covers, and tempered glass screen protectors protect smartphones from physical impacts, accidental drops, scratches, and environmental elements. Charging accessories, like wired chargers, wireless chargers, and power banks, prolong device uptime to maintain connectivity without interruption for users with intensive mobile usage-for instance, business people, travelers, and content creators. Audio accessories, like earbuds, headphones, Bluetooth speakers, and external microphones, enhance media consumption and the quality of communication, especially for entertainment, remote work, gaming, and online learning.

Mobile accessories also support enhanced device ergonomics and convenience. Mounts and holders are utilized in cars, homes, and commercial places to enable hands-free operation, navigation, and content viewing. Smart wearables like fitness bands and smartwatches converge with mobile devices to offer health tracking, notifications, and productivity features. Storage and connectivity accessories, including OTG drives, converters, and cables, allow data transfer, peripheral connectivity, and the extension of device capability. Furthermore, design-oriented accessories, such as customized cases and decorative elements, let users personalize their devices to reflect a choice of lifestyle and/or personal preferences. All in all, mobile accessories play a vital role in enhancing user experience, prolonging device life, and enabling seamless digital engagement of everyday activities.

What the Expert Says: Market Overview & Growth Drivers

The global mobile phone accessories market reached a value of USD 94.4 Billion in 2024. According to IMARC Group, the market is projected to reach USD 142.3 Billion by 2033, at a projected CAGR of 4.63% during 2025-2033. The convergence of technological advancements, evolving consumer behaviors, and increasing smartphone adoption across both developed and developing countries propels the mobile accessories market globally. One of the fundamental drivers is the continuing upgrade cycle for smartphones, wherein every new purchase creates recurring needs for protective and enhancement accessories. As mobile devices become more advanced-with better cameras, high-refresh displays, and power-consuming applications-users increasingly demand compatible accessories such as fast chargers, high-capacity power banks, precision audio products, and modular add-ons that complement these features. The growing adoption of wireless technologies, from Bluetooth-enabled audio to wireless charging standards, also drives demand for next-generation accessories that are more efficient and portable.

Another powerful driver is the movement toward digital lifestyles. Remote work, online education, mobile gaming, social media engagement, and streaming have made the dependence on smartphones heavier, hence increasing the demand for performance-enhancing accessories. Running parallel to this, the global focus on health and fitness has accelerated the adoption of smart wearables that integrate with mobile devices. Strong consumer inclination toward personalization acts as a propellant, favoring an active ecosystem of fashion-driven cases, skins, and customizable add-ons.

The expansion of e-commerce and improved distribution networks make it possible for the manufacturers to reach out to bigger markets, thus enabling the rapid launch of products and customization in volume. Additionally, emerging markets with increasing disposable incomes increase the size of addressable consumers; meanwhile, competitive pricing strategies by global and regional manufacturers further drive volume. Finally, continuous innovation in materials, practices related to sustainability, and design of products strengthens market momentum as manufacturers respond to environmental concerns and evolving user expectations.

Case Study on Cost Model of Mobile Accessories Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale mobile accessories manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed mobile accessories manufacturing plant in India. This plant is designed to manufacture 1 million unit of mobile accessories annually.

Manufacturing Process: The manufacturing processes for mobile accessories involve a sequence of design, material selection, fabrication of components, assembly, testing, and packing, which are again specific to the type of accessory, be it a charger, power bank, case, cable, earphone, or wearable. Designing the product, including prototyping, involves defining the technical specifications, ergonomics, durability, and compliance standards by the engineers. Once the design has been finalized, sourcing of materials is done, which includes sourcing plastics, metals, silicon, electronic components, circuits, batteries, and textiles. For hardware-based accessories like chargers, cables, and audio devices, electronic components are mounted on printed circuit boards through surface-mount technology on automated machines. Injection molding machines make casings and structural parts for power banks, cases, and chargers, assuring dimensional accuracy and strength. Compression or liquid silicone molding is used for soft accessories like covers made of silicone. The assembly stage, which is the integration of units such as PCBs, connectors, drivers, batteries, housings, and wiring into complete units, is also done through a combination of automated and manual processes after the individual components are fabricated. Quality control is at several checkpoints, including electrical safety testing, charging cycle verification, acoustic evaluation, tensile tests for cables, and environmental endurance. Additionally, wearables require added calibration of sensors and connectivity modules. Such products then go through surface finishing, branding, and packaging once performance and safety tests are cleared. Packaging refers to the design that protects the accessory during logistics by ensuring that it meets retail presentation requirements. Manufacturers now increasingly employ automation, lean principles in manufacturing processes, and sustainability as means to improve efficiency, reduce waste, and ensure consistent quality of their products irrespective of the market locations around the world.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

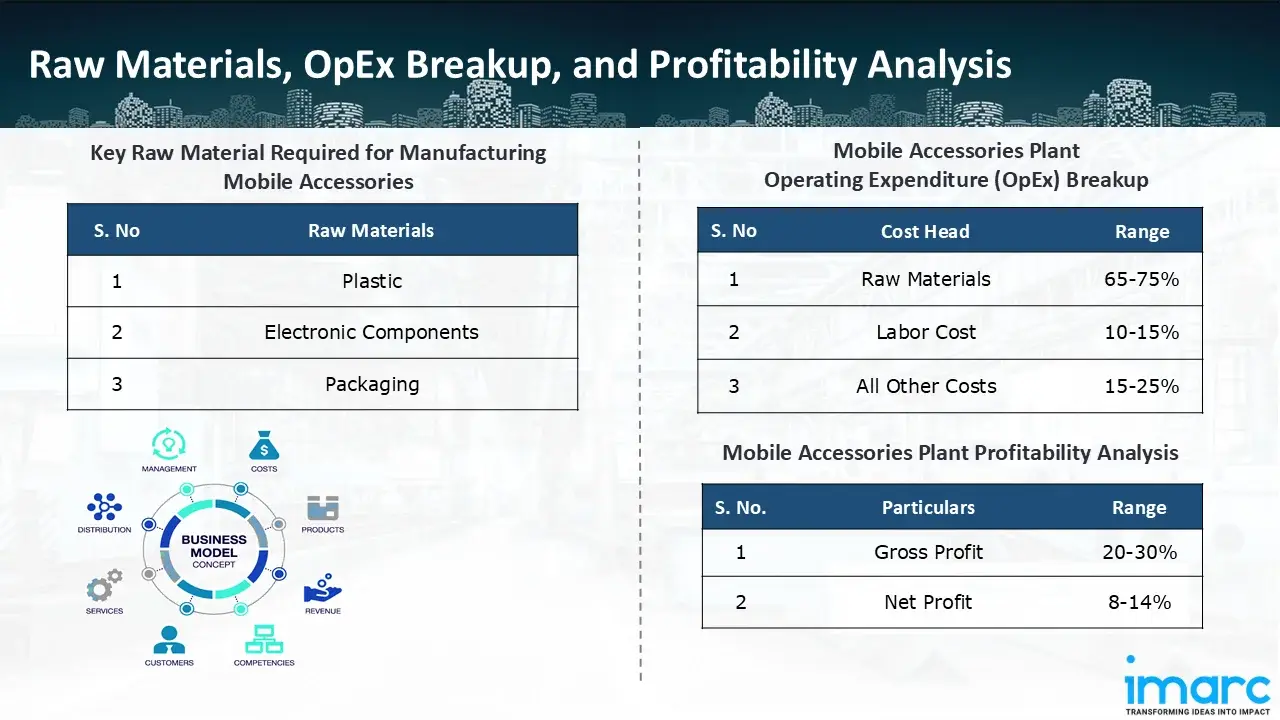

The basic raw materials required for mobile accessories manufacturing include:

- Plastic

- Electronic Components

- Packaging

Machine Section or Lines Required:

- Injection Molding

- SMT

- Assembly

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in mobile accessories manufacturing plant ranges between 65-75%, labor cost ranges between 10% to 15%, and all other costs ranges between 15-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-30%, and net profit lie between the range of 8-14% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the mobile accessories manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 1 million units of mobile accessories annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, the Indian lifestyle tech company DailyObjects has introduced Stack, an ecosystem of modular iPhone accessories. The new technology allows users to easily connect accessories like wallets, grips, and stands to compatible phone cases by combining mechanical and magnetic attachments.

- In October 2025, South Korean mobile accessories company Ringke has started building its first overseas production facility close to Sriperumbudur, Tamil Nadu with an initial investment of 20–25 crore. By April 2026, the plant is anticipated to be up and running, producing charging cables, GaN adapters, phone cases, and other accessories.

- In September 2025, Eveready Industries India Ltd., has declared its debut into the mobile accessories market. The calculated action demonstrates Eveready's readiness to adapt to changing consumer demands for digital connectivity and changing lifestyles.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104