Steel Rolling Products Cost Model: From Scrap Metal to Sustainable Value

_11zon.webp)

What is Steel Rolling Products?

Steel rolling products, encompassing hot-rolled, cold-rolled, and coated steel sheets and coils, form the backbone of numerous industrial applications, from automotive manufacturing to construction and infrastructure.

Key Applications Across Industries:

The cost of these products is influenced by a complex interplay of raw material prices, energy costs, labor, technological advancements, and logistical considerations. Moreover, steel producers are increasingly adopting sophisticated cost modeling techniques to optimize production efficiency and maintain competitive pricing. Fluctuations in iron ore and scrap steel prices, along with energy market volatility, directly affect production costs, while advancements in rolling technology and process automation help reduce per-unit costs and improve product quality. Additionally, regional disparities in tariffs, trade policies, and environmental regulations further shape the cost landscape, making it crucial for businesses to closely monitor these variables. Understanding these cost dynamics enables manufacturers, suppliers, and end-users to make informed strategic decisions, anticipate market trends, and manage procurement effectively in a rapidly evolving steel industry.

What the Expert Says: Market Overview & Growth Drivers

The global steel rolling products market size reached 471.7 Million Tons in 2024. According to IMARC Group, the market is projected to reach a volume of 524.2 Million Tons by 2033, at a projected CAGR of 1.2% during 2025-2033. The market for steel rolling products is primarily driven by expanding industrial activity and infrastructural development across emerging and developed economies.

In the construction sector, rising urbanization and the push for high-rise buildings fuel demand for high-strength steel sheets and coils. The automotive industry, transitioning toward lightweight and fuel-efficient vehicles, increasingly relies on advanced cold-rolled and coated steels. Additionally, the growing adoption of renewable energy infrastructure, such as wind towers and solar panel frameworks, creates further demand for specialized steel products. Global supply-demand dynamics are influenced by steel production capacity, raw material availability, and geopolitical factors impacting trade flows. Technological advancements in rolling mills, such as continuous casting and precision tempering, enhance efficiency, product consistency, and cost-effectiveness, incentivizing manufacturers to increase output. Environmental regulations and sustainability trends are also shaping demand for eco-friendly steel production processes, with producers investing in low-carbon technologies. These factors collectively drive the market for steel rolling products, positioning the sector for steady growth amid evolving industrial and economic landscapes.

Case Study on Cost Model of Steel Rolling Products Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium-to-large-scale steel rolling products manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed steel rolling products manufacturing plant in Zimbabwe. This plant is designed to produce 200,000 tons of steel rolling products per year.

Manufacturing Process: The steel rolling products plant transforms semi-finished billets into finished shapes like round bars, flat bars, angle irons, and channels through a series of thermal and mechanical operations. The process begins with the procurement and storage of steel billets in stockyards under controlled conditions to prevent rusting. These billets are then charged into a reheating furnace, where they are heated to around 1200°C, enabling plastic deformation for rolling. Heat transfer occurs mainly through convection and radiation from combustion gases and furnace walls, ensuring the steel reaches the required temperature based on rolling speed, size, and composition. Once red-hot, the billets enter the rolling mill, where they pass repeatedly through horizontal and vertical rolls to be reduced and shaped into the desired profiles. The rolled products are then sheared or cut into specific lengths using hot or cold shearing machines for precision. After cutting, inspection and straightening ensure dimensional accuracy, surface quality, and alignment, with any defects corrected before final approval. Surface treatment follows, beginning with acid pickling to remove mill scale and impurities, after which the steel is rinsed, dried, and galvanized by hot dipping into molten zinc for enhanced corrosion resistance. The galvanized products are cooled, inspected, and packaged. Finally, in the finished goods section, approved steel items are bundled, tagged, and temporarily stored for dispatch. Forklifts and cranes handle logistics, ensuring efficient loading onto trucks or railcars for timely delivery to customers.

_11zon.webp)

Mass Balance and Raw Material Required: The primary raw materials used in the steel rolling products producing plant are Steel Billets. For a plant producing 1 ton of steel rolling products, 1.06 ton of stell billets are required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

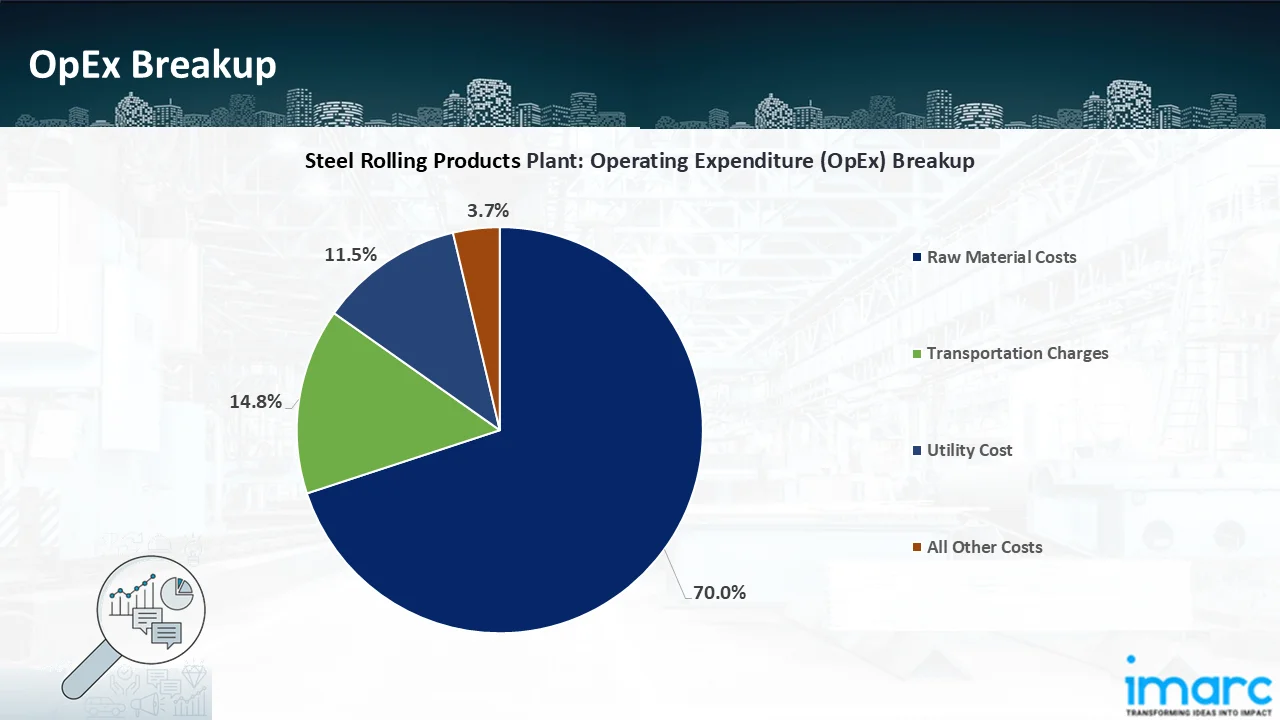

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

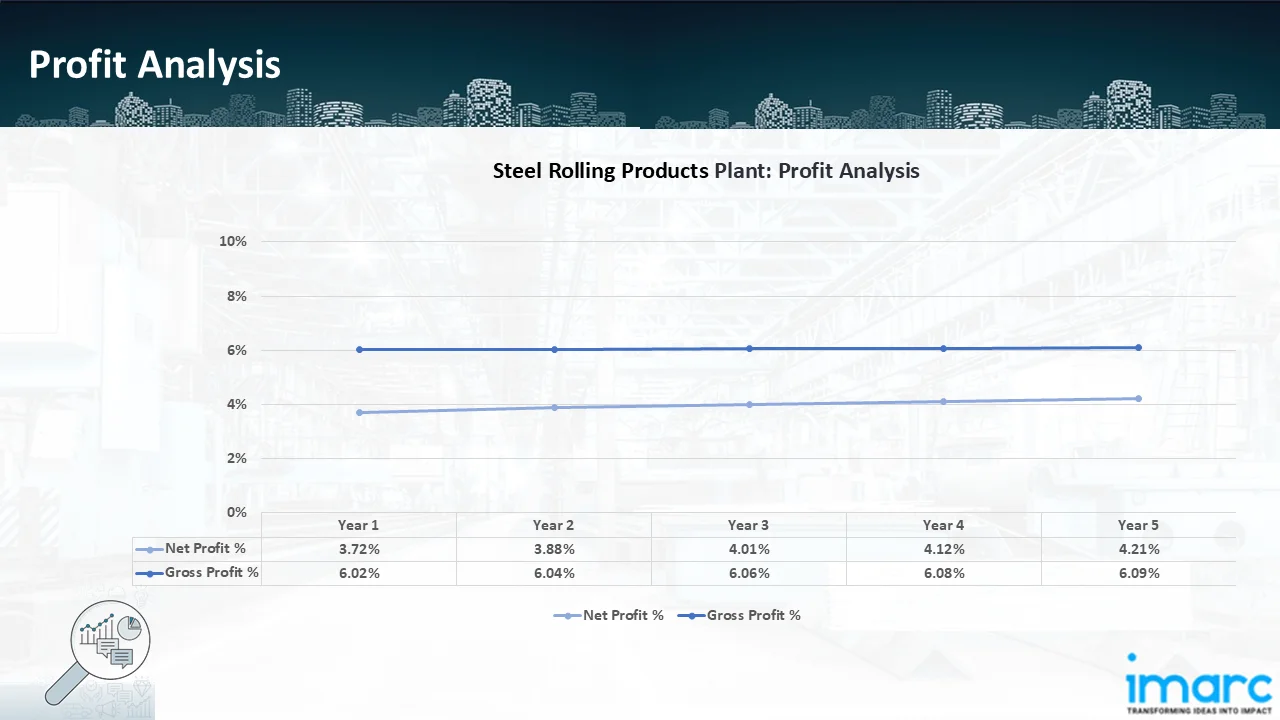

- Profitability Analysis Year on Year Basis: The proposed steel rolling products plant, with a capacity of 200,000 tons of steel rolling products per year, achieved an impressive revenue of US$ 117.48 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 6.02% to 6.09% by year 5, and net profit rises from 3.72% to 4.21%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the steel rolling products manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 200,000 tons of steel rolling products per year, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In September 2025, Salzgitter Group’s production routes under four of its subsidiaries had been verified by Association Internationale Sans But Lucratif (LESS AISBL), a non-profit association under Belgian law based in Brussels. LESS is a six-stage classification system which classifies steel manufacturing processes into six different classes depending on the given scrap content and CO2 emissions. The end products are also assigned a CO2 footprint determined by various standards.

- In April 2025, India Government imposed a 12% provisional safeguard duty for 200 days on five steel product categories, including hot rolled coils, sheets and plates, to protect domestic players from surge in imports.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104