Coconut Sugar Cost Model: Breaking Down the Cost Curve

What is Coconut Sugar?

Coconut sugar, also known as coconut palm sugar, is a natural sweetener derived from the sap of flower buds from the coconut palm tree, Cocos nucifera. It has traditionally been produced in various tropical countries like Indonesia, the Philippines, India, and Thailand, where coconut cultivation is plentiful.

Key Applications Across Industries:

This type of sugar is produced by tapping the flower buds of the coconut palm to collect the sap. The sap collected is then heated gently to boil off the water content, concentrate the sugars, and form a thick syrup. This thick syrup is subsequently cooled and crystallized into granules resembling brown sugar. Unlike white cane sugar, coconut sugar retains many of the nutrients present in the coconut sap, including traces of iron, zinc, calcium, potassium, and inulin-a dietary fiber with excellent prebiotic properties. It has a rich caramel-like flavor and a lower glycemic index, which makes it one of the popular alternatives for health-conscious consumers. Additionally, this sugar is minimally processed and requires no bleaching or additives. Often, it is considered more environmentally sustainable because coconut trees take up less water and space compared to the area usually required for sugarcane farming. With the current trend toward natural and unrefined sweeteners, coconut sugar has gained significant awareness in food and beverage manufacturing, especially in organic, vegan, and plant-based product development. It is therefore used rather invariably in bakery products, confectionery, beverages, sauces, and health foods, placing this sweetener in a strategic position linked to ecological awareness and nutrition, matching the modern clean-label concept.

What the Expert Says: Market Overview & Growth Drivers

The global coconut sugar market reached a value of USD 402.87 Million in 2024. According to IMARC Group, the market is projected to reach USD 657.87 Million by 2033, at a projected CAGR of 5.2% during 2025-2033. The global coconut sugar market is primarily driven by a combination of health, sustainability, and consumer preference trends. One of the key drivers is the rising demand for natural and low-glycemic sweeteners, as consumers increasingly seek alternatives to refined cane sugar and high-fructose corn syrup.

Coconut sugar’s lower glycemic index makes it suitable for individuals aiming to regulate blood sugar levels, including diabetics and those following low-sugar diets. Additionally, the growing awareness of natural and minimally processed foods has strengthened coconut sugar’s appeal among clean-label and organic product consumers. The ingredient’s nutrient content and natural caramel flavor also make it attractive for use in premium food products, artisanal confectionery, and health snacks. Sustainability is another crucial market driver. Coconut sugar production utilizes existing coconut trees without requiring additional deforestation or intensive water inputs, making it an environmentally responsible crop. The process also supports small-scale rural economies in coconut-producing nations, offering income diversification for farmers. Furthermore, the global shift toward plant-based and vegan diets has boosted the use of coconut sugar as a vegan-friendly sweetener alternative to honey. In the food manufacturing sector, major brands are increasingly reformulating products with natural sugars to align with evolving consumer preferences and regulatory scrutiny over added sugars. Lastly, expansion in global organic trade and fair-trade certifications is enhancing market access for producers, particularly from Southeast Asia. Collectively, these factors like health awareness, sustainable sourcing, ethical production, and versatility in applications are propelling the steady growth of coconut sugar in global food and beverage markets.

Case Study on Cost Model of Coconut Sugar Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale coconut sugar manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed coconut sugar manufacturing plant in India. This plant is designed to manufacture 250 tons of coconut sugar annually.

Manufacturing Process: The manufacturing process of coconut sugar involves several carefully controlled steps that transform the sweet sap of the coconut palm (Cocos nucifera) into a natural crystalline sweetener. The process begins with tapping the flower buds of mature coconut trees, typically aged between 10 and 15 years. Farmers make a precise incision on the unopened inflorescence and attach bamboo or stainless-steel containers to collect the sap, also known as neera or toddy. This sap is harvested twice daily, early in the morning and late in the afternoon, as it ferments quickly if left too long. Once collected, the sap is immediately filtered to remove impurities and transferred into large woks or vats for gentle heating. The heating process is done over moderate fire to gradually evaporate the water content while constantly stirring to prevent scorching. As the moisture reduces, the sap thickens into a syrup-like consistency, known as coconut nectar. Further heating continues until the syrup begins to crystallize, at which point it is removed from heat and allowed to cool. The cooled mass is then granulated or pulverized into fine sugar crystals and sieved for uniformity. No bleaching or chemical refining is used, preserving the natural color and minerals of the sap. The finished coconut sugar is then dried to reduce residual moisture, ensuring stability and shelf life, before being packaged in bulk or retail packs. The entire process is eco-friendly, often carried out by small-scale producers, and yields a nutrient-rich, caramel-flavoured sweetener prized for its natural origin and sustainable production.

Get a Tailored Feasibility Report for Your Project Request Sample

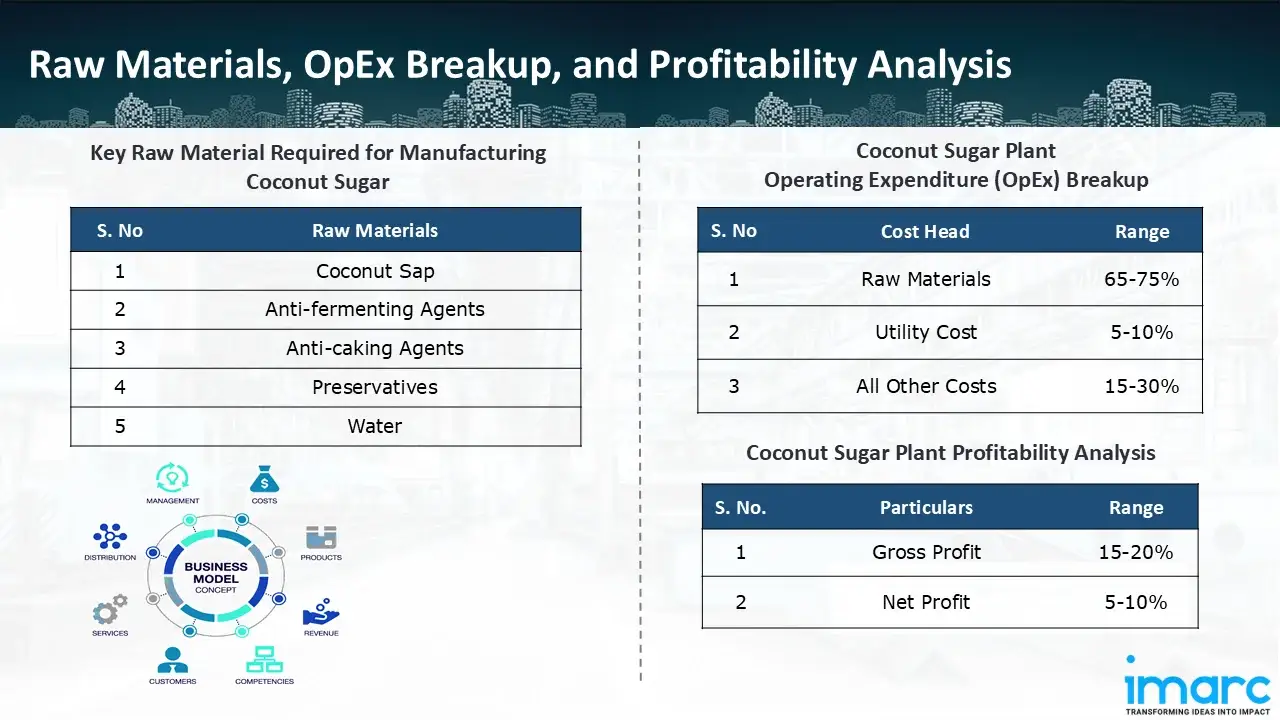

Raw Material Required:

The basic raw materials required for coconut sugar manufacturing include:

- Coconut Sap

- Anti-fermenting Agents

- Anti-caking Agents

- Preservatives

- Water

Machineries Required:

- Sap Collecting Containers / Tanks

- Filtration Units / Fine Mesh Strainers

- Evaporator / Boiling Pans

- Vacuum Evaporator

- Stirring Units

- Crystallizer / Sugar Pan with Agitator

- Cooling Trays

- Continuous Granulation Machine

- Tray Dryer / Fluidized Bed Dryer

- Rotary Drum Dryer

- Hot Air-Drying System

- Vibrating Sieve / Rotary Sieve

- Pulverizer

- Automatic Packing Machine

- Weighing and Filling Machine

- Sealing Machine

- Cooling Conveyor

- Storage Tanks

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a coconut sugar manufacturing plant ranges between 65-75%, utility cost ranges between 5% to 10%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the coconut sugar manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 250 tons of coconut sugar annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, the Delegation of the European Union (EU) to Indonesia hosted “Honouring Heritage and Authenticity: A Celebration of Geographical Indications” in Jakarta. The EU formally presented the GI certificate for Yogyakarta's Kulonprogo Coconut Sugar (Gula Kelapa Kulonprogo) during the event, adding it to the list of Indonesian goods already approved by the EU.

- In May 2025, the first official shipment of locally produced 5-star OCOP-rated organic coconut sugar, weighing more than 7 tonnes, to the United States was made from the Mekong Delta province of Tra Vinh.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104