Japan Industrial Robotics Market Forecast: Growth Drivers, Challenges, and Policy Impact by 2033

.webp)

Introduction to the Japan Industrial Robotics Market:

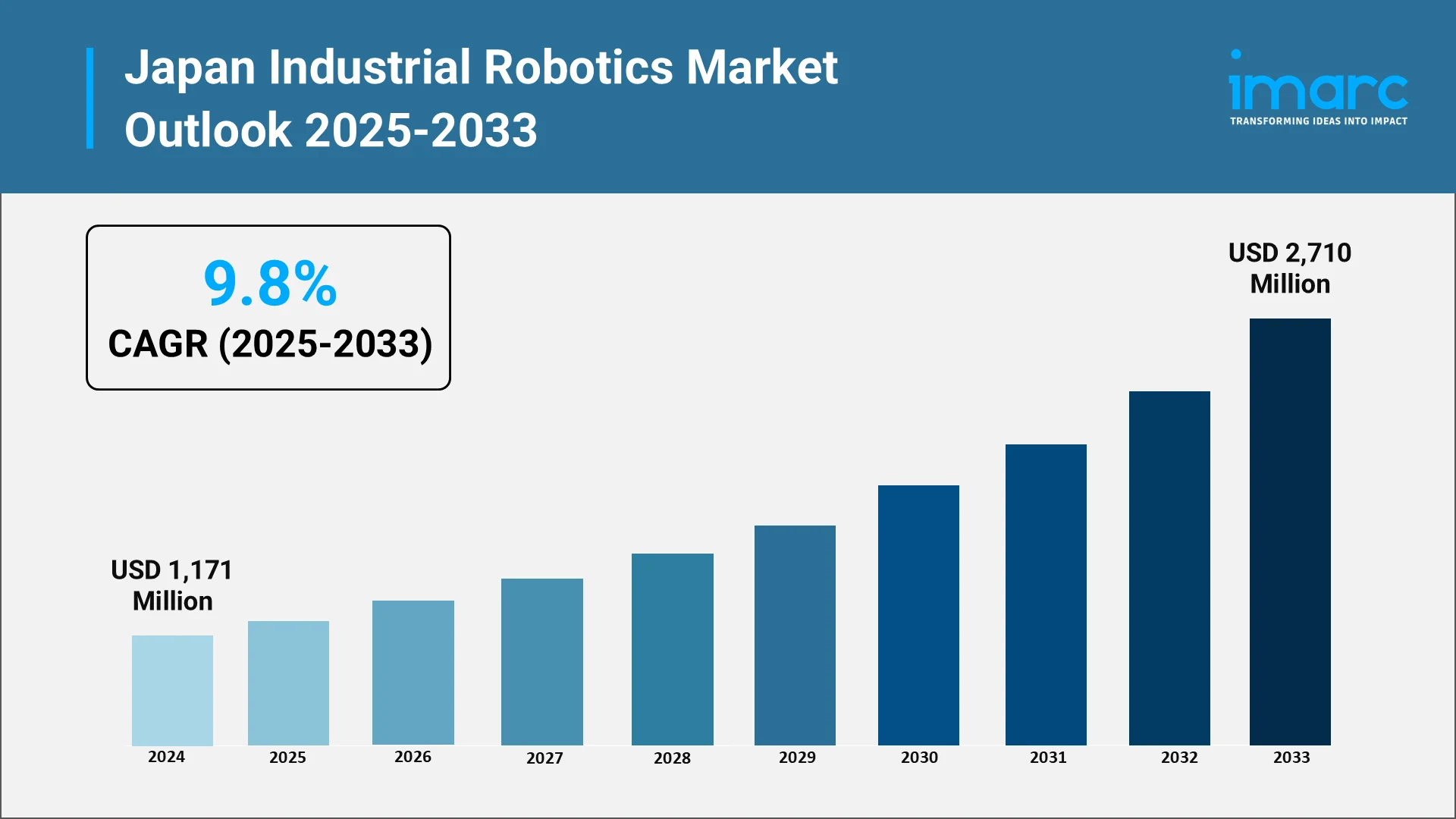

Japan has been a world leader in robotics, especially industrial, for decades. The nation's unflinching faith in technology development, precision manufacturing, and automation has made it a world leader in industrial robotics. Industrial robots have transformed the manufacturing process to become necessary equipment in today's manufacturing, helping companies increase productivity, retain quality, decrease errors in operations, and enhance efficiency in processes. The Japan industrial robotics market reached USD 1,171 Million in 2024, and looking ahead, the market to reach USD 2,710 Million by 2033, exhibiting a robust growth rate (CAGR) of 9.8% during 2025-2033.

Explore in-depth findings for this market, Request Sample

The market is transforming at a breakneck pace, fueled by innovation in artificial intelligence, machine learning, collaborative robots, and automation technologies that are reshaping production processes and workforce dynamics. With industries under increasing pressure to stay competitive and cost-effective, robotics adoption is becoming a core part of operational strategies. Knowledge of the market situation, drivers of growth, technological advancements, and main challenges is vital for businesses, investors, policymakers, and stakeholders to leverage opportunities and take advantage of the innovative industrial robotics industry in Japan.

Current Market Landscape and Trends:

- Japan's industrial robotics market is characterized by ongoing innovation and high-speed technological development. Automation technologies are being used more extensively in various industries such as automobile, electronics, consumer, and logistics. Industrial robots are no longer confined to repetitive operations; they increasingly undertake sophisticated tasks, work alongside human laborers, and adjust to changing production environments.

- Most prominent among them is the trend of collaborative robots, or cobots, that can safely coexist and work with humans. Cobots are gaining footing in industries where human skills and adaptability are still needed but providing firms with the means to marry human capabilities with robot accuracy.

- Another trend is the incorporation of artificial intelligence and machine learning into industrial robots. These technologies boost robot performance, allowing them to learn from the environment, make decisions on their own, and take on more complex tasks. This blend of robotics and intelligent systems is transforming industrial activities, making manufacturing more responsive, efficient, and future-proof.

- Japanese regional development illustrates that innovation is not localized in any single region. Urban centers and industrial areas both are pouring resources into robotic technologies, with research institutions, manufacturing plants, and technology clusters leading the way in the nation. This decentralized model for innovation facilitates broader implementation and diffusion of robotics know-how throughout the country.

- In 2024, Japan's automotive industry experienced its highest number of industrial robot installations in five years, with approximately 13,000 new units added. This 11% increase was driven by the diversification of drivetrains and a broader commitment to electric vehicle (EV) assembly, reflecting the industry's adaptation to emerging technologies and market demands.

- Furthermore, Japan's commitment to advancing robotics was showcased at the Japan Robot Week 2024, held in Tokyo from September 18 to 20. The event attracted about 100 exhibitors and 43,000 visitors, highlighting the nation's leadership in robotics innovation.

These developments underscore Japan's proactive approach to integrating robotics into various sectors, ensuring its position at the forefront of industrial automation.

Key Challenges Facing the Industrial Robotics Industry in Japan:

In spite of tremendous development prospects, the Japanese industrial robotics sector is confronted with some main issues that may affect adoption and growth.

- High Costs of Investment: Most industrial robotics is very expensive to install. Although the long-term advantage is improved efficiency and saving on labor, the initial cost can be too high for smaller businesses. This finance hurdle retards the wider deployment of sophisticated robotics in some sectors of the market.

- Integration Challenges: Integrating robots with existing production lines and processes is a challenging affair. Outdated processes, machinery, and legacy systems might not be compatible with contemporary robotic systems and would necessitate massive modifications or re-configurations. Robots need to communicate with other equipment smoothly in order to ensure productivity as well as operational reliability.

- Shortage of Skilled Workforce: There is a need for a qualified workforce with specialized technical skills in robotics, automation, and artificial intelligence to effectively deploy, operate, and maintain robotic systems. Japan's aging society and the poor inflow of young workers into technical professions have resulted in a shortage of available talent, potentially stifling the rate at which industrial robots are adopted.

- Ethical and Social Implications: Increased use of robotics poses ethical concerns regarding job loss, workforce change, and the balance between human and robot labor. Organizations need to traverse these challenges with caution to ensure that automation supports human employees and not displaces them.

Major Factors Driving Growth in the Japan Industrial Robotics Market:

A number of critical factors are propelling industrial robotics growth in Japan, presenting opportunities for corporations and technological developers.

- Filling Labor Gaps: Japan's population demographics, with its aging population and diminishing workforce, have raised the need for automation. Industrial robots are a viable solution, allowing industries to keep their productivity going even in the face of dwindling human labor supply. By mechanizing repetitive or physically strenuous tasks, robots alleviate labor gaps while human workers are allowed to concentrate on tasks that are higher in value.

- Technological Advances: Ongoing technological advancements in robotics, artificial intelligence (AI), and machine learning are greatly improving industrial robots' functionalities. Contemporary robots can execute advanced tasks with precise accuracy and efficiency, adjust to dynamic manufacturing environments, and integrate safely with human operators. These factors are making the use of robotics progressively appealing to industries needing dependable, high-performance automating solutions.

- In October 2025, a major collaboration between U.S. tech giant Nvidia and Japanese telecommunications company Fujitsu was announced, aiming to build foundational AI infrastructure in Japan by 2030. The initiative will target key sectors including healthcare, manufacturing, environmental technology, next-generation computing, and customer service. Leveraging Nvidia’s GPUs and Fujitsu’s local industry expertise, the project is designed to address societal challenges, such as Japan’s aging workforce, through a "humancentric" approach. This partnership highlights Japan’s ambition to lead in AI and robotics innovation, paving the way for advanced automation solutions with potential global applications.

- Comprehensive Development of Robotics in Japan: National robotics strategies in Japan lay out the grounds to encourage research, innovation, and commercialization of robot technologies, providing funding, subsidies, and regulation for industrial and service robots. More extensive smart society plans intend to implement digital technologies and robotics into everyday life, supporting productivity, societal well-being, and solving demographic and labor issues. Advanced regulatory reforms streamline certification, set standards for safety, and offer explicit deployment guidelines, lowering adoption barriers while implementing responsible use. Japan is also actively involved in international collaboration, drawing upon the best global expertise to design sophisticated AI-powered robotic systems, with a healthy robotics ecosystem and enhanced global leadership resulting.

Impact of Government Policies and Regulations:

The Japanese government has been pivotal in advancing robotics development through national strategies and frameworks that promote research, innovation, and deployment of robotic technologies across multiple sectors. These initiatives not only drive industrial growth but also address societal challenges, including labor shortages and efficiency improvements in healthcare and agriculture. In line with these efforts, Japan's Digital Agency announced a strategic partnership with OpenAI on October 2, 2025, aiming to integrate generative AI tools into public administration. This collaboration seeks to enhance the efficiency of government operations and set a precedent for AI adoption in public services.[CK5] Complementing this, various industries in Japan are increasingly adopting robotics to enhance productivity, maintain quality, and optimize production processes. High-precision sectors such as electronics and automotive manufacturing are particularly focused on advanced robots to meet stringent speed and quality requirements. Government policies and regulations further support this growth by ensuring safe adoption, encouraging innovation, and providing a structured environment for the development of tailored robotic solutions, creating a synergistic ecosystem that fuels both industrial demand and technological advancement.

Future Outlook for the Japan Industrial Robotics Market by 2033:

The future for Japan's industrial robotics market continues to be very optimistic with rapid growth expected in the years to come. Sustained technological innovations, favorable government measures, and increasing demand for automation are seen to propel continued market growth. Upcoming innovations will likely target strengthening artificial intelligence integration, human-robot collaboration, and autonomous operating capabilities. These advances will allow robots to execute more sophisticated tasks, move through ever-changing environments, and learn smartly to overcome new challenges in manufacturing and other industrial sectors. Outside of conventional production lines, robotics also promises to extend into logistics, healthcare, agriculture, and other industries by harnessing smart automation to maximize efficiency and open new channels for industrial and societal progress.

As robotics adoption accelerates, workforce dynamics in Japan are poised to transform significantly. While certain manual roles may decline, new opportunities will arise in the development, operation, and maintenance of robotic systems, highlighting the importance of education and training programs to equip workers with the necessary skills for an automated future. Between 2018 and 2022, approximately 1.4 million low-skilled workers were displaced by robots, while 2 million new jobs were created for skilled workers.

Alongside these shifts, ethical and social considerations will become increasingly important. Policymakers and organizations will need to address issues such as job displacement, privacy, and human oversight to ensure responsible implementation. By balancing technological innovation with social responsibility, Japan’s industrial robotics sector is expected to not only drive economic growth but also contribute to broader societal progress, demonstrating the transformative potential of intelligent automation across multiple domains.

Conclusion:

Japan’s industrial robotics market is poised for sustained growth, supported by technological innovation, demographic shifts, and proactive government initiatives. While challenges such as investment costs, integration complexities, and workforce shortages remain, strategic adoption of robotics offers transformative potential for industries and society. By fostering innovation, supporting workforce development, and emphasizing ethical implementation, Japan is set to maintain its position as a global leader in industrial robotics. The coming decade promises continued evolution, with robotics redefining productivity, workforce dynamics, and industrial capabilities across the country.

Unlock Japan’s Industrial Robotics Potential with IMARC Group:

- Data-Driven Market Research: Gain a deep understanding of Japan's industrial robotics landscape, including market dynamics, technology adoption trends, sector-specific applications, and innovations such as collaborative robots (cobots), AI-enabled automation, autonomous mobile robots (AMRs), and advanced sensing systems through comprehensive market intelligence reports.

- Strategic Growth Forecasting: Identify emerging opportunities in automation across automotive, electronics, healthcare, and logistics sectors, and anticipate the impact of technological evolution, government incentives, and industrial policy reforms on market expansion with detailed regional and industry-specific analysis for informed decision-making.

- Competitive Benchmarking: Assess competitive dynamics in Japan's industrial robotics market, analyze company strategies, monitor next-generation robotic innovations, and track partnerships, mergers, and acquisitions shaping the industry’s trajectory.

- Policy and Infrastructure Advisory: Navigate complex regulatory frameworks, government initiatives promoting robotics and automation, subsidies for smart manufacturing, and safety standards affecting deployment, adoption timelines, and operational integration across industries.

- Custom Reports and Consulting: Obtain tailored insights aligned with your organizational goals, whether introducing next-generation robotic solutions, investing in automation technologies, establishing manufacturing or R&D facilities, or formulating market entry strategies in Japan’s unique industrial ecosystem.

At IMARC Group, our mission is to empower robotics industry leaders with the intelligence and clarity needed to thrive in Japan’s rapidly evolving automation landscape. Partner with us to transform market insights into strategic advantage—because informed decisions drive sustainable growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104

.webp)