Australia Brakes and Clutches Industry: Electric Vehicle Demand, Major Sectors, Leading Companies

Introduction:

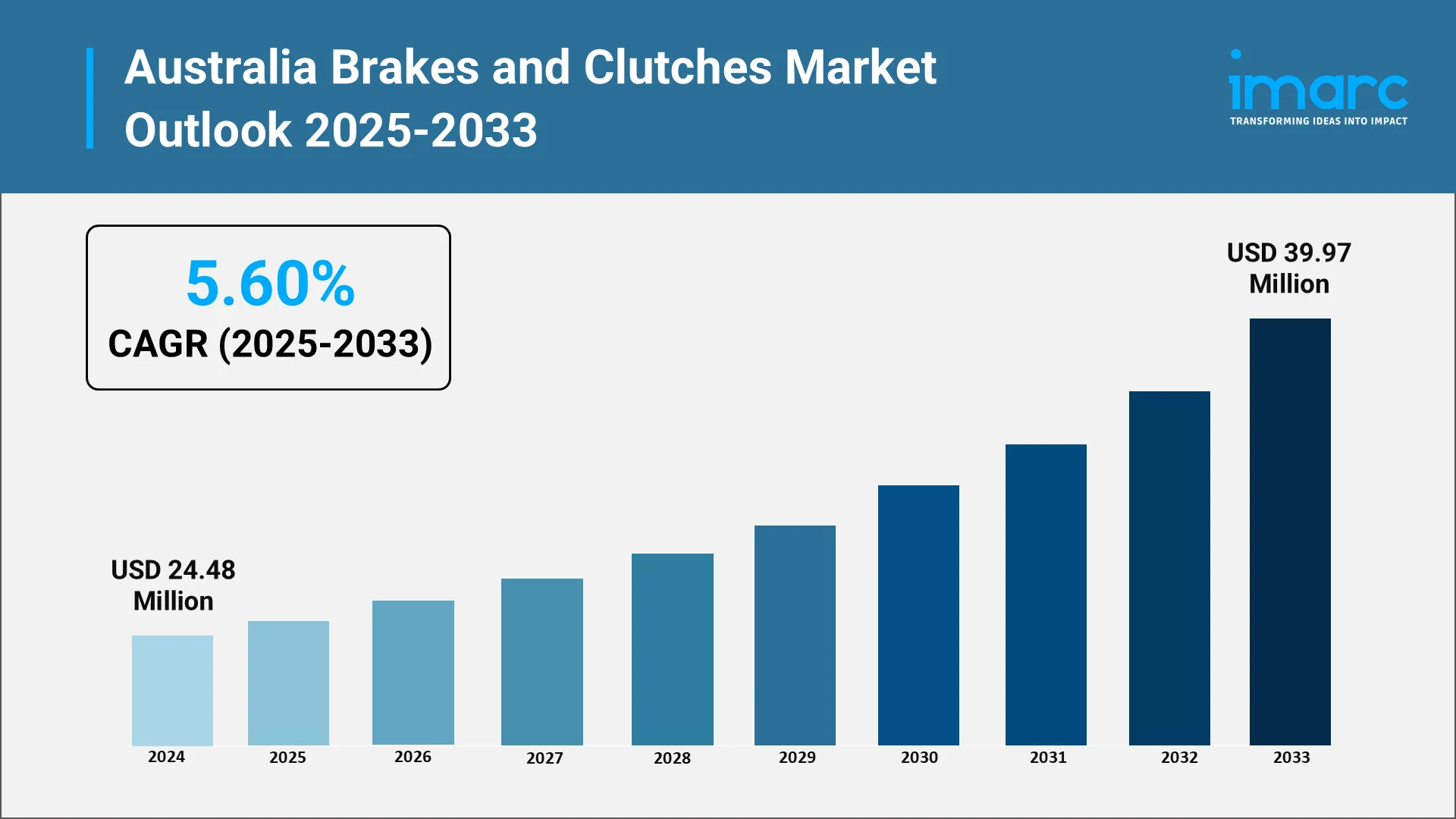

The Australian brakes and clutches industry plays a vital role in ensuring vehicle performance, safety, and efficiency across both automotive and industrial segments. As the nation transitions toward electric mobility and smarter manufacturing systems, the demand for advanced braking and clutch mechanisms is rising significantly. The Australia brakes and clutches market size reached USD 24.48 Million in 2024 and is projected to reach USD 39.97 Million by 2033, exhibiting a CAGR of 5.60% during 2025-2033. The industry is evolving beyond traditional friction-based systems, embracing digital control, material innovation, and sustainability-oriented solutions. With a strong focus on precision engineering, the market continues to attract investments from global automotive suppliers and domestic manufacturers seeking to meet the performance and safety requirements of modern vehicles and machinery.

Explore in-depth findings for this market, Request Sample

Key Aspects of the Market:

The Australian market for brakes and clutches is experiencing an era of gradual modernization led by electrification trends, urban mobility advancements, and industrial automation. Car manufacturers are focusing on lightweight materials, regenerative braking, and high-duty materials in their pursuit to make vehicles more efficient. Industrial applications from mining to heavy equipment also require strong, heat-resistant braking and clutch systems with the capability to bear extreme operating conditions.

In addition, growing demand for safety standards, energy efficiency, and sustainability is impacting procurement and product innovation. Manufacturers are incorporating sophisticated sensors and automation systems to improve precision and reliability, consistent with Australia's drive towards high-performance, environmentally sustainable engineering solutions. The intersection of electrification, automation, and digital control is likely to remake the way brakes and clutches are created, implemented, and serviced across industries.

Role of AI, Impact, and Benefits in the Australia Brakes and Clutches Industry:

Artificial Intelligence (AI) is emerging as a transformative force in the Australia brakes and clutches market. Its integration across manufacturing, predictive maintenance, and design optimization is driving measurable improvements in efficiency and reliability. AI algorithms analyze real-time data from sensors embedded within braking and clutch systems to predict wear, optimize performance, and prevent mechanical failures. This predictive capability significantly reduces downtime and enhances operational safety, particularly in heavy-duty applications such as mining vehicles and construction equipment.

In addition, AI supports simulation-driven product design, enabling manufacturers to model and test systems virtually before production. This minimizes material waste and accelerates innovation cycles. For electric vehicles (EVs), AI-driven regenerative braking systems are improving energy recovery rates and extending battery life, aligning with Australia’s sustainability objectives. In manufacturing facilities, AI-enabled process automation enhances production accuracy and consistency, allowing companies to achieve higher output while maintaining strict quality standards.

Overall, AI contributes to a data-centric, efficiency-driven industry that aligns with Australia’s broader digital manufacturing transformation agenda.

Automotive Market and Industrial Market:

Automotive Market:

The automotive segment represents one of the most dynamic areas of growth within the Australian brakes and clutches industry. With EV adoption accelerating, demand for lightweight, energy-efficient braking and clutch systems is increasing rapidly. Advanced braking technologies, such as electronic stability control, anti-lock braking systems (ABS), and regenerative braking, are becoming standard in new models. Manufacturers are also investing in brake-by-wire systems that replace traditional hydraulic mechanisms with electronic control for improved precision and safety.

Furthermore, the rise of hybrid and electric vehicles necessitates the development of specialized components that operate quietly, efficiently, and with minimal maintenance. Domestic suppliers are forming partnerships with global component manufacturers to co-develop EV-compatible braking systems, enhancing Australia’s local manufacturing capability. The focus on safety compliance and eco-friendly materials is also influencing the product landscape, promoting innovation in ceramic, carbon, and composite friction materials.

Industrial Market:

In the industrial sector, brakes and clutches play a critical role in applications such as mining, marine operations, construction equipment, and wind energy systems. The Australian mining industry, in particular, requires heavy-duty braking solutions designed for high torque, heat resistance, and reliability under extreme conditions. Clutches used in conveyor systems, drilling machinery, and industrial drives are being upgraded with smart control features for automation compatibility.

The shift toward Industry 4.0 technologies is driving demand for intelligent braking systems equipped with IoT sensors that monitor temperature, load, and friction data in real time. These insights help industrial operators enhance uptime and schedule maintenance efficiently. The adoption of energy-efficient electromagnetic and hydraulic braking systems further supports sustainability initiatives across manufacturing and resource-based sectors.

Both automotive and industrial applications are converging in their focus on smart technologies, durability, and lifecycle optimization positioning the Australian market as a hub of engineering advancement in braking and clutch systems.

Technological Advancements and Innovations in Brakes and Clutches:

- Mechatronic Integration for Enhanced Precision: The convergence of mechanical and electronic systems, known as mechatronic integration, is redefining brake and clutch design. This approach allows seamless coordination between sensors, actuators, and control units, resulting in faster response times, improved safety, and better energy efficiency. Mechatronic systems are especially valuable in electric and autonomous vehicles, where real-time performance monitoring and adaptive braking are essential. For industrial applications, mechatronics enable automated braking and clutch actuation with minimal human intervention, increasing precision and operational safety in high-load environments such as mining, manufacturing, and logistics.

- Brake-by-Wire and Clutch-by-Wire Systems: The transition from traditional hydraulic mechanisms to electronic “by-wire” systems marks a key innovation in the braking and clutch landscape. Brake-by-wire and clutch-by-wire technologies replace mechanical linkages with electronically controlled actuators, improving accuracy, reducing component wear, and enhancing safety responsiveness. These systems also enable integration with driver-assistance features like adaptive cruise control and stability programs. For manufacturers, by-wire systems simplify maintenance, reduce fluid-related failures, and allow the use of regenerative braking in electric vehicles, contributing to both sustainability and performance optimization across automotive and industrial applications.

- Regenerative Braking Systems for Electric Vehicles: Regenerative braking is transforming vehicle energy efficiency by converting kinetic energy during braking into electrical energy, which can be stored and reused. This innovation significantly improves fuel economy and extends battery life in electric and hybrid vehicles. In Australia’s growing EV market, regenerative braking supports national sustainability goals by reducing emissions and dependency on traditional braking systems. Manufacturers are developing intelligent control units that balance friction and regenerative braking for smoother driving experiences. In August 2025, Geely Auto Australia announced its plans to launch the Starray EM-i SUV, featuring its innovative E-Motive Intelligence Super Hybrid (EM-i) technology. This hybrid system boasts advanced regenerative braking, with a highly efficient petrol engine and electric motors, delivering seamless performance and exceptional driving range. This technology also lessens brake wear, reducing maintenance costs and enhancing overall vehicle lifecycle value.

- Advanced Materials and Friction Technologies: The development of advanced friction materials, such as carbon composites, ceramics, and graphene-infused compounds, is revolutionizing brake and clutch performance. These materials offer higher heat resistance, lower weight, and extended durability compared to conventional metallic systems. Lightweight materials contribute to better fuel efficiency and improved acceleration, especially in performance and electric vehicles. In industrial sectors, advanced composites withstand extreme operational stress, ensuring reliability in heavy-duty machinery. Continuous material innovation is also aligning with global environmental regulations by reducing harmful dust emissions and eliminating asbestos-based friction compounds. In May 2025, Disc Brakes Australia (DBA) expanded its Upgrade Performance Brake Kit lineup, now catering to popular 4x4s and performance vehicles. Kits feature advanced 4000 Series T3 rotors, high-friction pads, and larger calipers, enhancing braking performance and safety for towing, off-roading, and motorsport applications.

- 3D Printing and AI-Driven Design Optimization: Additive manufacturing and AI-based simulations are revolutionizing product development in the brakes and clutches industry. 3D printing allows rapid prototyping of complex components, significantly reducing design cycles and material waste. Combined with AI-powered predictive modeling, engineers can simulate performance under various stress conditions before physical production. This accelerates innovation while maintaining precision and quality. Manufacturers leverage these tools to create lightweight, optimized geometries that enhance cooling, durability, and energy efficiency. The fusion of digital manufacturing and AI analytics is setting new standards in customization, cost-effectiveness, and product reliability.

Opportunities and Challenges in the Australian Market:

Opportunities:

- Growing Electric Vehicle Adoption: The rising penetration of electric and hybrid vehicles presents significant opportunities for brake and clutch manufacturers. As EVs require regenerative braking and lightweight components, suppliers can innovate specialized friction materials and control systems optimized for battery efficiency. Collaborations with automakers to develop EV-compatible systems will enhance market reach and profitability.

- Expansion of Domestic Manufacturing Capabilities: Australia’s renewed focus on strengthening local manufacturing opens avenues for component producers to establish advanced production facilities. Leveraging automation, robotics, and precision machining, companies can localize supply chains and reduce dependency on imports, driving competitiveness in both domestic and export markets.

- Sustainability and Eco-Friendly Materials: The global transition toward sustainable manufacturing creates opportunities for firms that adopt eco-friendly materials and recyclable components. Development of non-asbestos, low-dust friction materials and biodegradable lubricants aligns with environmental standards while attracting environmentally conscious clients.

- Integration with Autonomous and Smart Vehicles: The growing trend of vehicle automation is creating opportunities for brakes and clutches with embedded sensors and electronic control systems. These components support safety automation features such as adaptive braking and collision avoidance, positioning suppliers to participate in the next generation of intelligent mobility solutions.

- Aftermarket Expansion and Digital Platforms: The expansion of e-commerce and digital platforms for automotive parts distribution is creating opportunities in the aftermarket segment. Companies can leverage digital sales channels, predictive analytics, and online diagnostics to enhance customer service and expand market visibility.

Challenges:

- High Import Dependence and Supply Chain Disruptions: A significant challenge for the Australian brakes and clutches industry lies in its dependence on imported components and raw materials. Supply chain volatility, rising freight costs, and geopolitical tensions can affect production timelines and pricing stability, emphasizing the need for localized sourcing strategies.

- Rapid Technological Obsolescence: As braking and clutch technologies evolve rapidly, companies face challenges in keeping pace with digitalization, automation, and electrification requirements. Continuous investment in R&D and workforce upskilling is essential to remain competitive, which may pressure profit margins for smaller manufacturers.

- Stringent Safety and Environmental Regulations: Compliance with evolving safety, emissions, and recycling standards adds operational complexity. Manufacturers must invest in advanced testing and certification processes to meet national and international quality benchmarks, increasing operational costs and time-to-market.

- Rising Raw Material and Energy Costs: Fluctuations in the cost of steel, aluminum, ceramics, and energy inputs pose challenges for pricing and profitability. Firms need to adopt energy-efficient processes and explore alternative materials to mitigate cost pressures while maintaining product quality.

- Limited Skilled Workforce in Advanced Manufacturing: The transition toward automation and AI-enabled systems demands highly skilled technicians and engineers. Australia’s shortage of technical talent in precision manufacturing and mechatronics may hinder industry scalability unless addressed through workforce development programs and partnerships with training institutions.

How IMARC Group is Guiding Innovation in the Brakes and Clutches Industry:

IMARC Group enables stakeholders across the automotive and industrial components sectors to navigate evolving market dynamics through data-driven insights and strategic intelligence. Our expertise supports organizations in adapting to electrification, automation, and sustainability trends transforming the Australia brakes and clutches market.

- Market Insights: We analyze key trends such as regenerative braking, brake-by-wire systems, and advanced materials that are reshaping design and manufacturing standards across vehicle and industrial applications.

- Strategic Forecasting: Our forecasts help clients anticipate demand shifts, identify growth segments, and align with Australia’s expanding EV ecosystem and automation initiatives.

- Competitive Intelligence: IMARC tracks innovations, mergers, and partnerships among leading OEMs and suppliers, providing actionable insights for market positioning and portfolio optimization.

- Policy and Regulatory Analysis: We evaluate evolving safety, performance, and environmental regulations that influence product development and certification.

- Customized Consulting: IMARC’s tailored consulting services guide clients in operational efficiency, supply chain optimization, and technology adoption.

Through precise analytics and foresight, IMARC Group helps organizations strengthen their competitive edge and drive innovation in the evolving brakes and clutches landscape.For detailed insights, data-driven forecasts, and strategic advice, see the complete report here: https://www.imarcgroup.com/australia-brakes-clutches-market

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104

.webp)