Coconut Processing Cost Model: Turning Nature into Value

Coconut is an important tropical crop with a wide array of uses, and hence it is considered the "Tree of Life." The fruit, leaves, trunk, and roots of coconuts yield a wide range of products. Each part has economic value and, therefore, provides a means of livelihood in many rural communities and agro-industrial development in tropical regions such as Southeast Asia, South Asia, and the Pacific Islands. The coconut fruit consists of three main parts: the husk, shell, and kernel, each requiring specialized processing into various types of products. The kernel is processed for edible products like coconut oil, desiccated coconut, coconut milk, and virgin coconut oil. The husk provides coir fiber and coco peat used for textiles, ropes, mattresses, and horticulture, while the shell is used for charcoal, activated carbon, and handicrafts. The water and sap of the coconut are processed into beverages, vinegar, and natural sweeteners like coconut sugar. Modern processing involves mechanical extraction, drying, fermentation, and refining technologies that maintain quality and increase efficiency. The advances in integrated coconut processing enable manufacturers to attain zero-waste production where each by-product is used commercially. The industry has evolved from traditional, small-scale processing to technologically advanced facilities producing high-value derivatives for food, cosmetics, pharmaceuticals, and bio-based materials. This adaptability and the growing focus on sustainability make coconut processing an essential part of the circular bioeconomy, supporting both export-oriented and domestic industries in tropical economies. The global coconut products market reached a value of USD 21.7 Billion in 2024. According to IMARC Group, the market is projected to reach USD 53.4 Billion by 2033, at a projected CAGR of 10.0% during 2025-2033. The global coconut processing market is driven by increasing demand across different consumer and industrial sectors for natural, sustainable, and plant-based products. A vital reason is growing consciousness about health and wellness, which has increased consumption of coconut-derived food products like virgin coconut oil, coconut milk, flour, and water. These are widely considered healthy options compared to synthetic or animal-based products, catering to the demands of consumers following vegan, keto, and clean-label diets. On a separate note, coconut oil, activated carbon, and coconut water are increasingly being used in the cosmetics and personal care segments for their moisturizing, antioxidant, and antimicrobial properties, respectively, coinciding with the global trend of organic and chemical-free formulations. On the sustainability front, coconut processing meets zero-waste manufacturing principles, as close to all parts of the coconut can be valorized into a commercial product. The growth of the bio-based economy and demand for natural fibers have strengthened the market for coir products and coco peat in agriculture and soil conditioning. In addition, technological improvements in extraction and drying methods have improved efficiency, extended shelf life, and allowed high-value niche products to be developed, including coconut sugar, coconut cream, and plant-based dairy alternatives. Government initiatives in major producing countries, the Philippines, Indonesia, India, and Sri Lanka are promoting coconut-based rural industries to improve farmer incomes and increase export revenues. Besides this, global sustainability certifications and fair-trade standards also enhance market access to producers. Overall, the convergence of health awareness, sustainable sourcing, and technological innovation continues to drive robust global growth in coconut processing industries.

Trending Insights on Coconut: Latest News and Developments

- In October 2025, a "Land Purchase and Sale Agreement" between Indonesia Huanlejia and PT PRIMA COCO INDONUSA was announced by Huanlejia Food Group Co., Ltd. Following commercial talks, Indonesia Huanlejia paid 90 billion Indonesian rupiah (excluding value-added tax, or around RMB 38.71 million) for land, factory buildings, equipment, and other assets after consulting the asset appraisal value.

- In September 2025, Andhra Pradesh’s Industries and Rural Development Minister Kondapalli Srinivas announced the establishment of a Common Facility Centre (CFC) at Pedapatnam Lanka in Razole constituency with an investment of `9.96 crore under the MSE-CDP initiative to support coconut-based companies.

- In August 2025, a Memorandum of Understanding (MoU) for the construction of a cutting-edge coconut processing plant on the island was recently signed between the government of Barbados and the Republic of India. The MOU's signature is regarded as a daring move that will strengthen bilateral collaboration and improve food processing capacities.

Case Study on Cost Model of Coconut Processing Plant

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale coconut processing plant. We developed a comprehensive financial model for the setup and operation of a proposed coconut processing plant in India. This plant is designed to produce 1,200 tons of coconut oil annually.

Processing Flow: The processing of coconuts encompasses a sequential series of processes that systematically extract multiple products with high value from different parts of the fruit, guaranteeing maximum resource utilization with minimum waste. Processing commences with the gathering and selection of mature coconuts, harvested at around 12 months to ensure optimal oil and kernel content within the nut. Dehusking removes the fibrous outer husk from the coconut, the raw material for coir fiber and coco peat, which are used in horticulture and manufacturing, among other industries. The dehusked nuts are then deshelled, revealing the white kernel inside the hard shell; the shell will later be used to make charcoal, activated carbon, and handicrafts. After paring, washing, and grating, the kernel is used as raw material in the preparation of products such as coconut oil, desiccated coconut, coconut milk, and flour. For edible products, the grated coconut may be subjected to mechanical pressing to extract milk, which may then undergo further processing into coconut cream or be dried to get desiccated coconut. During oil extraction, the meat is first dried into copra; it then undergoes mechanical pressing or solvent extraction to yield coconut oil, which is refined, bleached, and deodorized for consumption or industrial purposes. Alternatively, the fresh coconut meat is cold-pressed to extract virgin coconut oil, retaining its aromatic and nutritional properties. The coconut water extracted during processing is filtered, pasteurized, and packaged as a beverage, while the sap collected from the inflorescence is reduced to coconut sugar. Quality control through the process ensures purity, hygiene, and standardization of the product, thereby enabling the coconut processing industry to provide a wide array of food, cosmetic, and industrial products from that single sustainable resource.

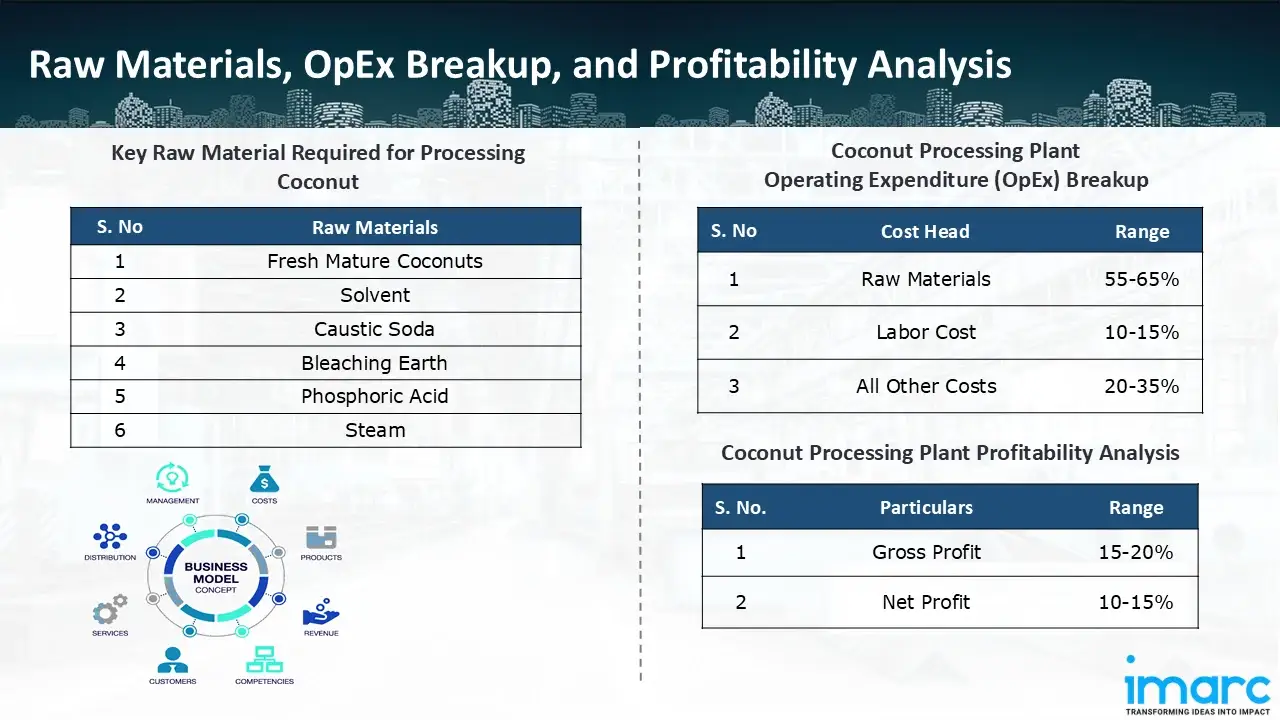

Raw Material Required:

The basic raw materials required for coconut processing include:

- Fresh Mature Coconuts

- Solvent

- Caustic Soda

- Bleaching Earth

- Phosphoric Acid

- Steam

Machineries Required:

- Coconut Dehusking Machine

- Coconut Shelling Machine

- Washing And Grading Conveyor System

- Coconut Grating Machine

- Coconut Oil Expeller (Screw Press / Hydraulic Press)

- Degumming Unit

- Neutralization Tank

- Bleaching Unit

- Deodorization Chamber

- Volumetric / Gravity Filling Machine

- Automatic Capping and Labelling Machine

- Effluent Treatment Plant

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a processing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a processing plant effectively. Opex in a processing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a processing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a coconut processing plant ranges between 55-65%, labor cost ranges between 10% to 15%, and all other costs ranges between 20-35% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion:

Our financial model for the coconut processing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, processing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 1,200 tons of coconut oil annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale processing ventures.

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104