Paper Bag Manufacturing Cost Analysis: The Paper Fold Equation

What are Paper Bags?

Paper bags can be defined as the final product made from paper-based material such as kraft paper, recycled paper, or specialty paper, used for packing or storing products. Paper bags come in different shapes and sizes with varying strength, ranging from flat-bottom paper bags, gusseted paper bags, and handled paper bags. Paper bags can be biodegradable, can be recycled, and can be made from renewable resources. Paper bags can be considered environmentally friendly packing alternatives because they offer adequate strength and can be printed.

Key Applications Across Industries:

Paper bags have a wide range of uses spanning the entire commercial, industrial, and consumer realm owing to their malleability and eco-friendly nature. In the supermarket industry, paper bags are commonly used by clothing stores, supermarkets, pharmacies, and specialty shops for the purpose of carrying purchased products. Their amenability to customization with brand, logos, and marketing messages makes paper bags an effective tool for their intended purpose. In the foodservice industry, paper bags are commonly employed for the purpose of carrying baked products, fast foods, groceries, and fruits, among others.

In the industrial and business context, paper bags are used for carrying heavy material like cement, chemicals, fertilizers, animal feeds, grains, and construction materials through multi-ply kraft paper bags having valve-bottom or sewn-bottom closure. In online shopping and logistics, deliveries are increasingly made using paper bags meant for light cargo transit in fashion, cosmetics, and lifestyle commodities.

Paper bags also have uses in institutional environments for things like paper bag use during conferences and other corporate events. Another agricultural use for paper bags would be for the packaging of seeds. Paper bags can also be used for crop protection. Paper bags can also be recycled and composted. This makes the paper bag very appropriate for use by environmentalists and other businesspeople who avoid the use of plastics.

What the Expert Says: Market Overview & Growth Drivers

The global paper bag market reached a value of USD 6.0 Billion in 2024. According to IMARC Group, the market is projected to reach USD 8.6 Billion by 2033, at a projected CAGR of 4.05% during 2025-2033. The factors propelling the global paper bag market include environmental norms, awareness about sustainability, and a shift in consumer demand for sustainable packaging alternatives. Among the prime driving forces, a growing government pressure on single-use plastic bags is prominent. Effective restrictions on single-use plastic bags by governments and local administration, in the form of taxes or bans, are driving manufacturers to adopt sustainable alternatives made from paper. Also, paper bags are biodegradable, making them a suitable option.

Another very important factor is the growing awareness amongst consumers. There is an increasing demand amongst consumers for packaging that is linked with responsible consumption and taking care of the environment. As a result, there is a shift towards using paper bags so that the sustainable and corporate social responsibility aspects are improved. It is very common in the retail and food-service industry.

Rise in the organized retail, food delivery, and e-commerce markets accelerates the demand for bags. Growth in the number of supermarkets, convenient stores, and e-commerce platforms augments the demand for robust, affordable, and brandable solutions. Paper bags are highly printable, helping the brand utilize bags as marketing channels as well as meeting the sustainability requirements.

Research and development of papermaking and bag-converting equipment have enabled the development of stronger, more moisture-resistant, and heavier-capacity paper bags. Moreover, the development of recycled papers and sustainably produced kraft papers enhances supply chain stability and management of bag costs. At the same time, other factors such as business sustainability programs and global commitments to reduce carbon footprints promote the use of paper bags as an alternative to plastic bags used by business organizations.

Case Study on Cost Model of Paper Bag Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale paper bag manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed paper bag manufacturing plant in India. This plant is designed to manufacture 20 million units of paper bag annually.

Manufacturing Process: The paper bag manufacturing process consists of various paper handling and converting processes involved in producing paper rolls into useful and long-lasting packaging materials. This process begins by choosing suitable paper types, mainly kraft paper produced either from virgin or recycled paper pulp. After paper selection, it is fed into bag manufacturing machinery in rolls, and then it is unrolled and printed if printing is needed. This printing process is done using either the flexographic or offline printing process and using biodegradable inks. After printing, the paper is moved into the forming sections where the paper is cut and formed into the desired shape of the bag, whether that be flat top or gusseted. Adhesive lines stick the sides and bottoms of the bags together, giving the bag its shape. For bags that have handles, handle-forming units can create the paper handles by twisting paper or by making flat handles that can then be glued or sewed onto the bag. For industrial paper bags, there can be more than one layer of paper formed together in order to create improved strength, during which time the valve insertion and bottom sewings occur. The resultant pouches undergo the drying and curing phases to achieve adhesive bonding strength. Quality control tests are performed to check the size, seam strength, resistance to load, and print quality. The manufactured pouches are packed after counting and bundling them for delivery. Various manufacturing procedures involve the use of more automation, waste reduction, and recycling to achieve efficiency and sustainability.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

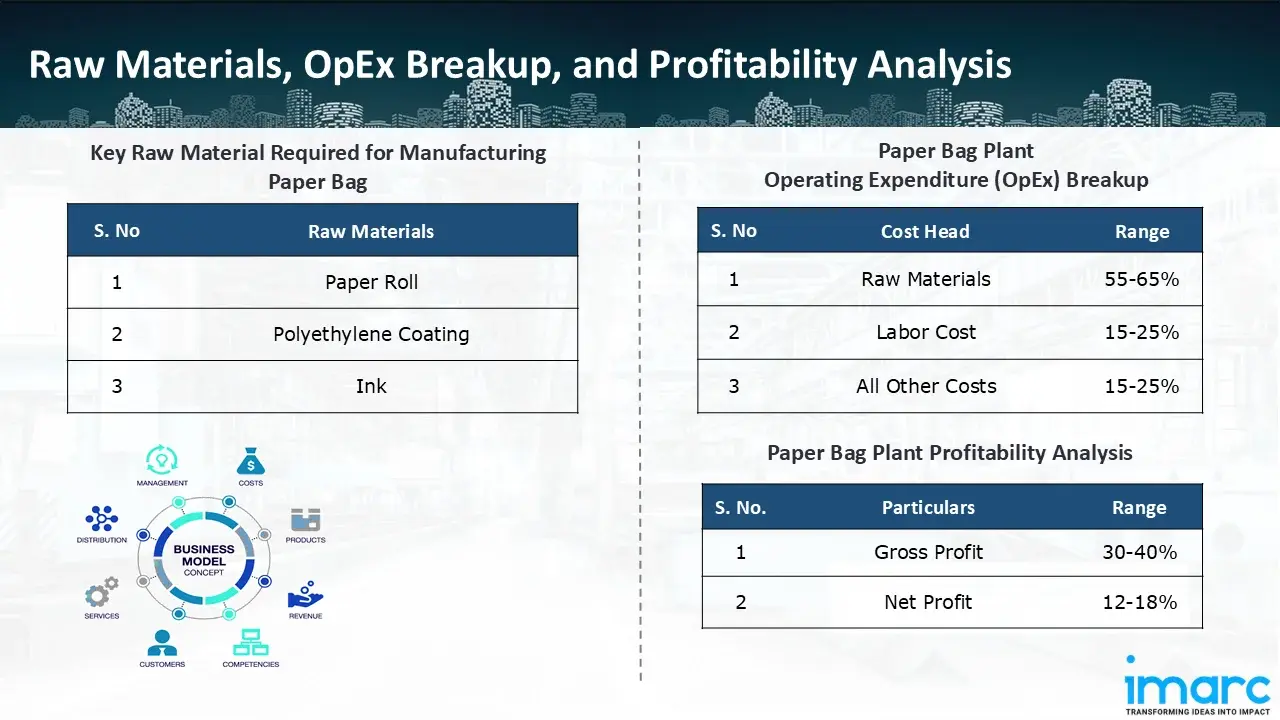

The basic raw materials required for paper bag manufacturing include:

- Paper Roll

- Polyethylene Coating

- Ink

Machine Section or Lines Required:

- Printing

- Cutting

- Forming

- Bottom Sealing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in Paper bag manufacturing plant ranges between 55-65%, labor cost ranges between 15% to 25%, and all other costs ranges between 15-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 12-18% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the paper bag manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 20 million units of paper bag annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In December 2025, Coveris announced that it will provide entirely recyclable paper-based packaging for the US confectionary goods of Pladis Global, the UK-based snacking behemoth. For Pladis' confectionery brands in the US, Coveris has created pre-made paper block bottom bags to use as supplementary packaging. The new product replaces the non-recyclable polypropylene/paper composite bags used by the owners of the Godiva chocolate brand and McVitie's biscuits.

- In June 2025, Mondi, a world leader in environmentally friendly paper and packaging, announced introducing its re/cycle PaperPlus Bag Advanced, a high-performance paper bag with a substantially lower plastic content that protects goods that are sensitive to humidity. For products that are sensitive to humidity, the paper bag's thin, high-performance 20 µm film keeps moisture out.

- In September 2024, Novolex, a leader in packaging innovation, sustainability, and choice, announced that it has purchased American Twisting's assets. American Twisting is a reputable producer of handles made of twisted paper that are used to make paper bags.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104