Sebacic Acid Cost Model: Assessing the Profitability Potential

_11zon.webp)

What is Sebacic Acid?

Sebacic acid is a naturally occurring dicarboxylic acid, a long-chain organic compound with two carboxyl functional groups. It is mainly produced from castor oil through cracking and purification in a significant industrial process, as it is a valuable bio-based chemical with major industrial relevance.

Key Applications Across Industries:

The white flaky or crystalline powder is cherished for its superior properties, such as high thermal stability, corrosion resistance, and the ability to form long-lasting polymers. Its primary application is as a essential monomer in nylon 610 synthesis, a high-performance engineering plastic with superior strength, toughness, and chemical resistance and purity from abrasion. Outside nylons, sebacic acid is a basic component in lubricants, plasticizers, hydraulic fluids, cosmetics, and pharmaceuticals production. With its renewable feedstock base, it holds a privileged position in the transition towards sustainable and environmentally friendly industrial feedstocks on a global level, addressing a diverse array of end-use industries ranging from automotive and aerospace to personal care and coatings.

What the Expert Says: Market Overview & Growth Drivers

The global sebacic acid market size reached USD 301.4 Million in 2024. According to IMARC Group, the market is projected to reach USD 410.8 Million by 2033, at a projected CAGR of 3.33% during 2025-2033.

The global market for sebacic acid is driven by a number of interrelated drivers. The most notable is the growing need in the automotive and aerospace sectors for high-performance, low-weight engineering plastics such as nylon 610, which improve fuel economy and wear resistance. Supporting this is a strong regulatory and consumer demand for bio-derived and sustainable materials, which places sebacic acid in an attractive green replacement role over petrochemical-derived adipic acid. Additionally, the extensive expansion of the cosmetics and personal care market, for which sebacic acid is utilized in creams, lotions, and as an ester precursor, further drives market growth. The market is also supported by strong expansion of developing economies, especially those of the Asia-Pacific area, a region that is a major center of castor bean production as well as of industrial production. Lastly, continuous R&D in new applications, including in biodegradable polymers and high-end lubricants, are establishing new growth paths, cementing the market's innovative development beyond its conventional applications.

Case Study on Cost Model of Sebacic Acid Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale sebacic acid manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed sebacic acid manufacturing plant in United States. This plant is designed to produce 20,000 tons of sebacic acid annually.

Manufacturing Process: Sebacic acid is mainly manufactured from castor oil, extracted from the seeds of the castor plant (Ricinus communis). The seeds are washed, ground, and mechanically or solvent extracted (usually hexane) to yield crude oil, which is filtered and degummed to ensure purity. The oil, which is high in ricinolein, is hydrolyzed to liberate ricinoleic acid, the primary precursor. Hydrolysis is usually performed through saponification, where sodium hydroxide is used to treat the castor oil to produce sodium ricinoleate, which is then acidified to give ricinoleic acid. Enzymatic hydrolysis employing lipases is an alternative greener but more expensive process. The ricinoleic acid is then heated under pyrolysis in the presence of a low concentration of alkali catalyst (NaOH) at 200–250°C in a vacuum or inert gas atmosphere. This triggers oxidative cleavage, decarboxylation, and β-scission, producing sebacic acid and co-products such as 2-octanol and undecylenic acid. Upon reaction, neutralization with sulfuric acid, cooling, and crystallization isolate sebacic acid from by-products. Filtration or centrifugation eliminates impurities. Crude sebacic acid is purified through recrystallization in hot solvents, filtered, and dried to yield high-purity flakes or powder. Lastly, the product is placed in water-resistant containers under controlled conditions to be stable for application in polymers, lubricants, cosmetics, and pharmaceuticals.

_11zon.webp)

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials used in the sebacic acid producing plant are castor oil, caustic soda, sulfuric acid, zinc oxide and activated carbon. For a plant producing 1 ton of sebacic acid, 2 ton of castor oil, 1.15 ton of caustic soda, 1.42 ton of sulfuric acid, 0.006 ton of zinc oxide, and 0.020 ton of activated carbon is required.

Machineries Required:

- Castor Oil Storage Tanks (SS316, Instrumented)

- Alkali Cleavage Reactors (SS316, DCS/PLC)

- Neutralization Tanks (Lined)

- Intermediate Storage Tanks (Lined)

- Steam Boiler (Gas Fired, Fully Auto)

- Fully Automatic Centrifugal Machines (Solid-Liquid Separation)

- Crystallizers (Cooling Type)

- Vacuum Filters (Nutsche/Belt Type)

- Dryers (Tray or Rotary Type)

- Effluent Treatment Plant (ETP)

- Cooling Tower

- Heat Exchangers (Shell & Tube)

- Centrifugal Pumps (SS/MS)

- Upgraded DCS/PLC Control System

- Utility Piping + Automated Valves

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

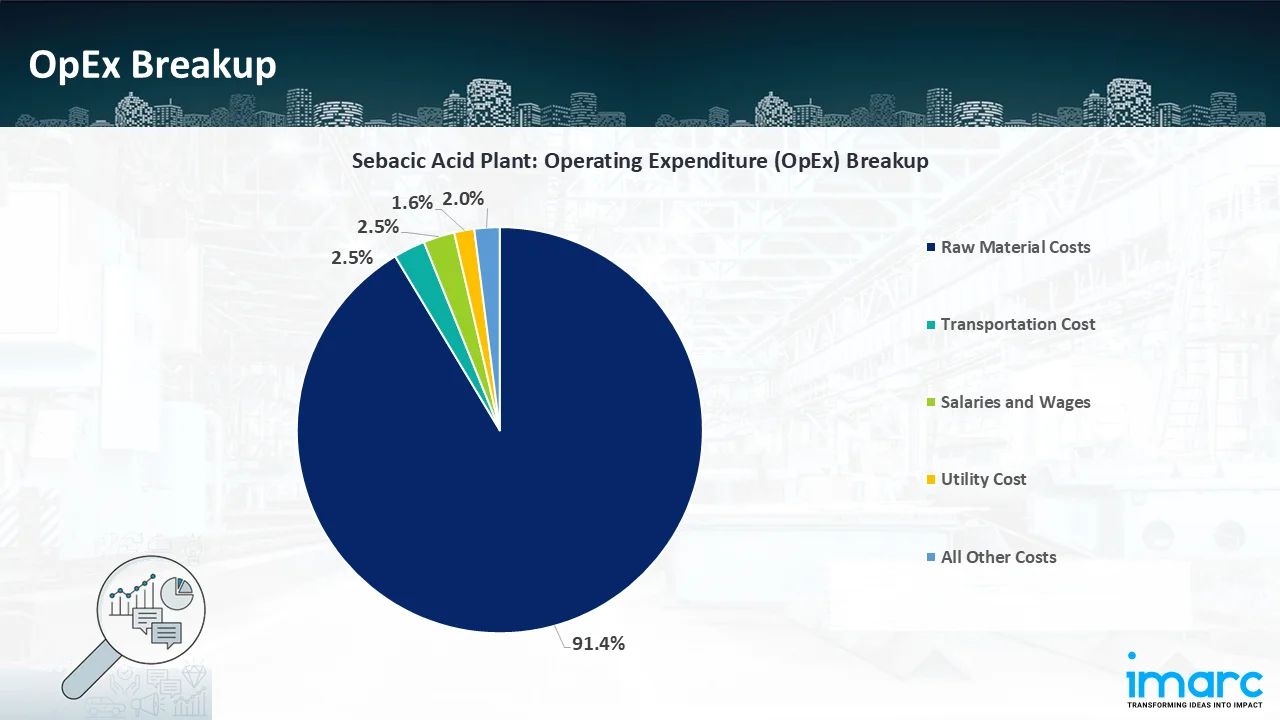

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

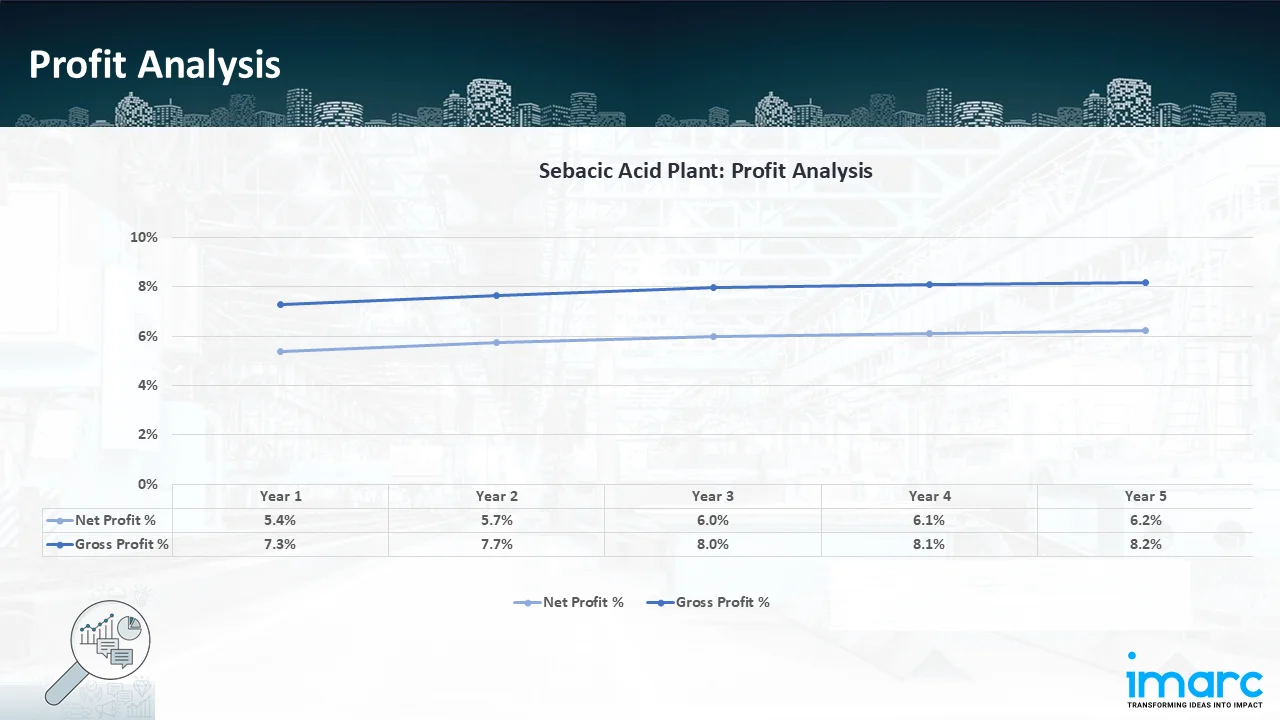

- Profitability Analysis Year on Year Basis: The proposed sebacic acid plant, with a capacity of 20,000 tons of sebacic acid annually, achieved an impressive revenue of US$ 102.4 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 7.3% to 8.2% by year 5, and net profit rises from 5.4% to 6.2%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the sebacic acid manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 20,000 tons of sebacic acid annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In February 2025, the 2024 results of Pragati, the world's first sustainable castor bean initiative, was published by BASF, Arkema, and Jayant Agro-Organics. In the 2023–2024 season, Pragati concluded its eight-year run. The project was jointly launched in May 2016 by BASF, Arkema, Jayant Agro-Organics, and Solidaridad, the organisation responsible for carrying out the project.

- In January 2025, W. R. Grace has sold a fine chemical facility in Albany, Oregon to Lacamas Laboratories, a speciality chemical manufacturer situated in Portland, Oregon. An US$ 86.2 million contract to establish production of two energetic precursors (4-nitroanisole and 1,3,5-trichlorobenzene), two non-energetic precursors (salicylic acid and sebacic acid), and three stabilizers/burning rate moderators (diphenylamine, ethyl centralite, and methyl centralite) was given to Lacamas Laboratories in February 2024.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104