GCC Bridge Construction Market Insights: Mega Projects Driving Regional Connectivity

Introduction:

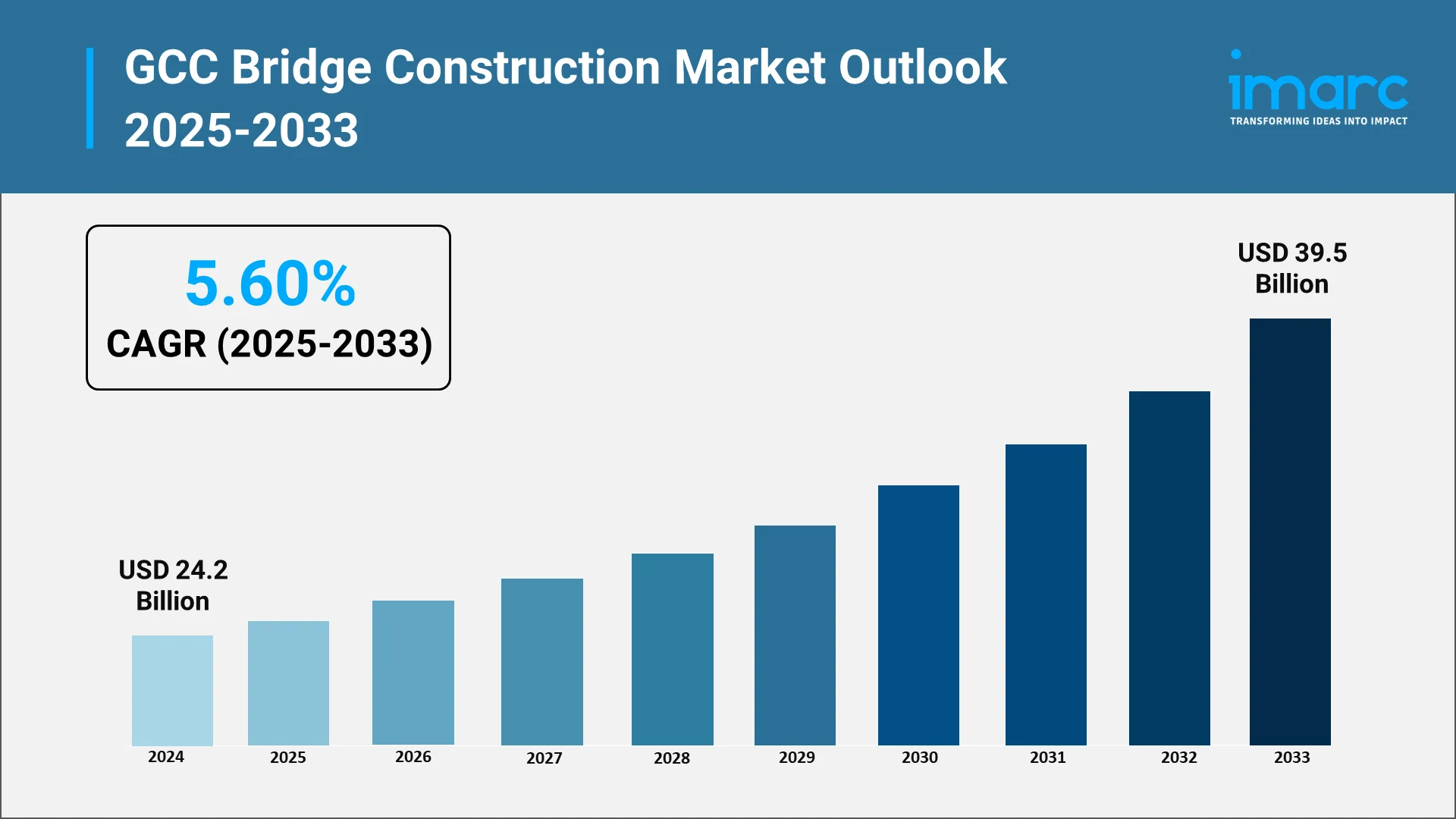

The GCC bridge construction market represents a vital component of the region's ambitious infrastructure transformation agenda, serving as a cornerstone for enhanced mobility, economic integration, and sustainable urban development across the Gulf states. In 2024, the GCC bridge construction market size reached USD 24.2 Billion. Bridge construction initiatives throughout Saudi Arabia, the United Arab Emirates, Kuwait, Qatar, Oman, and Bahrain are fundamentally reshaping transportation networks and enabling seamless connectivity between major urban centers, industrial zones, and strategic trade corridors.

The significance of bridge construction extends beyond mere transportation functionality, as these projects embody the strategic vision of GCC governments to diversify their economies and position the region as a global hub for trade, tourism, and innovation. Mega infrastructure projects have emerged as powerful catalysts for economic growth, creating substantial employment opportunities and attracting foreign direct investment. Government investment programs, particularly those aligned with national development blueprints, have allocated considerable resources toward transportation infrastructure enhancement.

Explore in-depth findings for this market, Request Sample

How Vision 2030 is Transforming the GCC Bridge Construction Industry:

Vision 2030 and comparable national transformation programs across the GCC have fundamentally redefined the trajectory of bridge construction development, establishing unprecedented momentum for infrastructure investment and technological innovation throughout the region. These comprehensive strategic frameworks prioritize transportation infrastructure as an essential enabler of economic diversification, with bridge construction projects receiving substantial government backing. The emphasis on developing world-class transportation networks has catalyzed a new generation of bridge construction endeavors characterized by architectural excellence, engineering sophistication, and sustainability principles. This transformative approach has encouraged collaboration between public sector entities and international construction specialists, fostering knowledge transfer and positioning the GCC as a regional leader in infrastructure development.

Key Industry Trends:

- Rising Investments in Transportation and Cross-Border Connectivity Projects

The GCC bridge construction market is experiencing remarkable expansion driven by escalating investments in transportation infrastructure and cross-border connectivity initiatives. Governments have recognized that robust transportation networks serve as fundamental prerequisites for achieving economic diversification objectives, prompting substantial capital allocation toward bridge construction projects. Cross-border connectivity projects reflect the collaborative spirit characterizing contemporary Gulf infrastructure development, designed to reduce transit times and facilitate movement across international boundaries.

- Deployment of Advanced Construction Materials and Technologies

The sector is witnessing significant transformation through deployment of advanced construction materials and innovative technologies. Engineering firms are increasingly adopting high-performance concrete formulations, corrosion-resistant steel alloys, and composite materials that withstand harsh Gulf climates. The integration of prefabrication, modular construction techniques, Building Information Modeling, and advanced project management platforms has revolutionized project execution, enabling accelerated timelines and improved quality control.

- Growth of Smart and Sustainable Infrastructure Development

Bridge designs increasingly incorporate intelligent transportation systems, sensor networks, and monitoring technologies enabling real-time structural health assessment and traffic flow optimization. Sustainability considerations have become integral to planning, with projects incorporating energy-efficient lighting, solar installations, and green building certification programs that encourage environmentally responsible practices throughout project lifecycles.

- Expanding Urban Development and Coastal Expansion Projects

Rapid urbanization has created substantial demand for bridge construction infrastructure supporting emerging urban centers. In January 2025, Abu Dhabi's Department of Municipalities and Transport opened two new bridges worth AED 315 million, designed to reduce peak hour traffic delays by 80%. Bridge construction plays pivotal roles by connecting new residential communities, commercial districts, and industrial zones to existing transportation networks.

- Integration of Public-Private Partnerships in Infrastructure Funding

Public-Private Partnership models have transformed bridge construction financing, enabling governments to leverage private sector expertise and capital. These collaborative arrangements distribute project risks between public authorities and private consortiums, facilitating access to international construction expertise and global capital markets beyond traditional government budget allocations.

Market Segmentation and Regional Insights:

IMARC Group has categorized the GCC bridge construction market based on type of bridge, material used, and application.

Type of Bridge Insights:

On the basis of the type of bridge, the market has been divided into beam bridges, arch bridges, suspension bridges, and cable-stayed bridges.

- Beam Bridges - Beam bridges represent the most common and cost-effective bridge type in the GCC, widely utilized for short to medium spans across highways, urban intersections, and railway crossings due to their straightforward design and rapid construction timelines.

- Arch Bridges - Arch bridges are favored for their aesthetic appeal and structural efficiency in spanning medium distances, particularly in heritage areas and tourist destinations where architectural distinction complements functional transportation requirements.

- Suspension Bridges - Suspension bridges are deployed for long-span crossings over water bodies and valleys, offering elegant solutions for challenging geographical terrains while accommodating heavy traffic loads and providing iconic architectural landmarks.

- Cable-Stayed Bridges - Cable-stayed bridges have gained prominence in the GCC for their modern aesthetic and structural versatility, combining engineering innovation with visual impact to serve as signature infrastructure elements in major urban development projects.

Material Used Insights:

Based on the material, the market has been segmented into concrete bridges, steel bridges, and composite bridges.

- Concrete bridges dominate the GCC market due to their durability in harsh climatic conditions, cost-effectiveness for medium-span projects, and widespread availability of materials and construction expertise throughout the region.

- Steel bridges are increasingly specified for projects requiring rapid construction, long spans, and seismic resistance, with advanced corrosion-resistant treatments addressing the Gulf's challenging saline and humid environmental conditions.

- Composite bridges utilizing combined concrete and steel elements are emerging as preferred solutions for optimizing structural performance, reducing construction time, and achieving superior strength-to-weight ratios in complex bridge designs.

Application Insights:

On the basis of the application, the market has been segregated into road and highway and railway.

- Road and highway applications constitute the largest segment of GCC bridge construction, driven by extensive transportation network expansion programs supporting urban growth, economic corridors, and connectivity enhancement between major population centers.

- Railway bridge construction is experiencing accelerated growth aligned with GCC railway network development initiatives, including high-speed rail projects, metro systems, and regional rail connectivity programs supporting sustainable transportation objectives.

Country Insights:

Region-wise, the market has been segmented into Saudi Arabia, United Arab Emirates, Qatar, Kuwait, Oman, and Bahrain.

- Saudi Arabia GCC bridge construction market is expanding with the largest infrastructure investment portfolio driven by Vision 2030 initiatives, extensive urban expansion in major cities, and mega-project developments requiring comprehensive transportation connectivity solutions.

- The United Arab Emirates maintains robust bridge construction activity concentrated in Abu Dhabi and Dubai, focusing on urban mobility enhancement, coastal development connectivity, and integration of emerging districts within metropolitan transportation networks.

- Qatar's bridge construction sector is characterized by strategic infrastructure projects supporting post-event legacy planning, urban development in Doha and surrounding areas, and enhancement of transportation networks connecting residential, commercial, and industrial zones.

- Kuwait's bridge construction market is driven by delayed mega-project implementation under Vision 2035, with emphasis on addressing urban congestion, supporting new city developments, and improving connectivity to major port and industrial facilities.

- Oman's bridge construction focuses on addressing challenging mountainous terrain, wadi crossings, and coastal connectivity requirements, supporting tourism development, resource transportation, and integration of remote regions within national infrastructure networks.

- Bahrain's compact geography creates specific demand for bridges connecting island territories, land reclamation areas, and supporting continued urban expansion, with potential cross-border connectivity projects enhancing regional integration prospects.

Forecast (2025-2033):

The GCC bridge construction market size is expected to reach USD 39.5 Billion by 2033, exhibiting a growth rate (CAGR) of 5.60% during 2025-2033, reflecting strong foundational support from national governments and sustained investment appetite. The market is anticipated to maintain a strong upward trajectory, demonstrating significant acceleration in its overall value and volume of projects delivered throughout the region. This growth is expected to be consistent with the broader regional infrastructural expenditure across the Gulf states, driven by several powerful and long-lasting factors that ensure a robust GCC bridge construction market demand for years to come.

Several key demand drivers will sustain growth throughout the forecast period.

- Government Investments Under Vision 2030/2035 Programs represent the primary catalyst. With more than a million residential units, Saudi Arabia invested $1.3 Trillion in infrastructure and real estate projects to diversify its economy away from oil, ensuring a steady pipeline of bridge projects and providing visibility for construction companies and supply chain participants.

- Expansion of Logistics and Trade Corridors constitutes another major driver. These logistics zones require extensive bridge infrastructure for highway access, internal circulation, and multimodal connections, creating sustained demand across various bridge typologies.

- Rising Urbanization and Population Growth will continue driving urban bridge demand. The GCC's urban population is projected to reach approximately 90% by 2030, necessitating continuous expansion of transportation networks, including elevated expressways, flyovers, and pedestrian bridges.

- Increasing Demand for Durable and Resilient Transportation Infrastructure reflects growing climate change awareness. As per the International Journal of Bridge, Engineering, Management and Research, bridges must be designed to withstand increased risks posed by climate change impacts such as rising sea levels, extreme temperatures, and seismic events, with resilient design principles including energy-absorbing materials and floating bridge concepts enhancing long-term durability. This emphasis on resilience will drive demand for advanced materials and engineering solutions, potentially increasing project values while reducing long-term maintenance costs.

Conclusion:

The GCC bridge construction market stands at a pivotal juncture characterized by unprecedented opportunity, technological innovation, and strategic importance for regional economic development. The confluence of ambitious national development programs, sustained government investment, and evolving infrastructure requirements creates a dynamic environment favoring continued expansion. Major trends including rising investments in cross-border connectivity, deployment of advanced construction technologies, emphasis on smart and sustainable infrastructure, expanding urban development, and integration of Public-Private Partnerships define the contemporary landscape.

The transformation of bridge construction from purely functional infrastructure to strategic assets embodying architectural excellence and technological sophistication reflects the maturation of the GCC construction sector. Regional governments' commitment to infrastructure investment ensures sustained momentum while creating opportunities for capacity building and development of local expertise positioning the GCC as a regional leader in infrastructure innovation.

Partner with IMARC Group for Comprehensive Bridge Construction Market Intelligence:

At IMARC Group, we recognize that navigating the dynamic GCC bridge construction market requires deep, data-driven intelligence that empowers strategic decision-making.

- Data-Driven Market Research: Deepen your understanding of bridge construction market dynamics, government investment patterns, and technological advancements through our comprehensive reports. Our analysts track project pipelines, tender activities, and competitive developments across all six GCC member states.

- Strategic Growth Forecasting: Predict emerging trends from modular building systems and 3D printing applications to shifts in public-private partnership structures. Our forecasting combines quantitative modeling with qualitative expert insights, delivering projections segmented by bridge type, application, materials, and geography.

- Competitive Benchmarking: Analyze competitive dynamics, review project portfolios of leading contractors, and monitor technological capabilities and strategic partnerships. Our intelligence helps you understand positioning strategies, success factors, and market gaps.

- Policy and Infrastructure Advisory: Stay ahead of regulatory developments, government procurement frameworks, and national infrastructure strategies. Our policy monitoring tracks changes in sustainability requirements, local content mandates, PPP frameworks, and technical specifications.

- Custom Reports and Consulting: Access tailored insights aligned with your objectives—whether introducing new technologies, pursuing specific opportunities, establishing regional presence, or evaluating acquisition targets. From feasibility studies and market entry strategies to due diligence support and competitive assessments, we deliver actionable intelligence.

At IMARC Group, our mission is to empower infrastructure leaders, construction companies, material suppliers, technology providers, and investors with the clarity and intelligence required for success. Our experienced analysts combine industry expertise with rigorous research methodologies to deliver insights that translate into competitive advantage. Please visit, https://www.imarcgroup.com/gcc-bridge-construction-market, for more details.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104

.webp)