Copper Sulphate Cost Model: From Mineral to Market

_11zon.webp)

What is Copper Sulphate?

Copper sulphate is an inorganic chemical made up of copper, sulfur, and oxygen that is best known for its crystalline blue color and varied uses. Most often found as copper sulphate pentahydrate (CuSO4·5H2O), it is prized for its water solubility, stability, and fungicidal activity.

Key Applications Across Industries:

Primary characteristics are that it is a fungicide, herbicide, algicide, and electrolyte used in industrial applications. It also serves as a precursor for the manufacture of other compounds of copper and as a laboratory reagent. The substance is produced through controlled chemical reactions of copper with sulfuric acid or by secondary processes from copper-containing by-products. Copper sulphate has varied uses in agriculture (as fungicides, animal feed supplements, and soil additives), mining (flotation processes), electroplating, chemical manufacturing, and textiles. From a financial point of view, it provides inexpensive solutions to other industries while being useful for sustainable farming through enhanced crop output. In the future, copper sulphate remains significant as a multipurpose industrial and agricultural chemical, with the future tied to increasing demand for agrochemicals, renewable energy, and water treatment sectors.

What the Expert Says: Market Overview & Growth Drivers

The global copper sulphate market size reached 441.7 Kilo Tons in 2024. According to IMARC Group, the market is projected to reach 528.4 Kilo Tons by 2033, at a projected CAGR of 2.0% during 2025-2033. The market for copper sulphate is fueled by its universal application in agriculture as a fungicide and animal feed micronutrient supplement.

Growing demand for increased agricultural output in developing countries further fuels its growth. Copper sulphate is also used as a flotation agent in ore processing in the mining sector, representing another major demand driver. Water treatment processes and electroplating operations also use copper sulphate because of its antifungal activity and conductivity. Further demand is supported by its function as a feedstock for specialty chemicals and catalysts. Its application in renewable energy storage technology, especially as an electrolyte for flow batteries, represents future trends. Environmental pressures are inducing developments in greener formulations and controlled application methods to minimize ecological footprint. Competitive strengths are cost-effectiveness, multiple end-use purposes, and comparatively easy production processes. Obstacles, nevertheless, are raw material price volatility and environmental rules restricting excessive agri-use. Sustainability issues are more prominent, with the industry developing safer methods of application and encouraging recycling from industrial effluents. The industry has responded by investing in environmental-friendly processes, expanding capacity in the Asia-Pacific region, and tightening supply chain monitoring.

Case Study on Cost Model of Copper Sulphate Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium-scale copper sulphate manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed copper sulphate manufacturing plant in Peru. This plant is designed to produce 10,000 tons of copper sulphate annually.

Manufacturing Process: The production of copper sulphate is initiated with the purchase of raw materials, mainly pure copper scrap, industrial-grade sulfuric acid, and distilled water. Scrap needs to be oil-free, free from oxidation, or brass/bronze contamination to facilitate efficient dissolution. Industrial-grade sulfuric acid (66° Baumé) is diluted to a nominal concentration of ~20% in acid-resistant vessels, with controlled heat to maximize reaction kinetics. The acid is then diluted and loaded into a lead-lined reactor that houses copper scrap. To speed up the process, compressed air is sometimes oxygen or ozone-enriched is sparged at the bottom of the reactor while mechanical agitation maintains even mixing. Copper is oxidized in a controlled manner at 50–60°C to produce copper sulphate in solution. Progress of the reaction is followed by measuring free acid concentration and visual scrap consumption. After completion of dissolution, the mixture is filtered through acid-resistant units to eliminate undissolved residues. The solution is then evaporated gently in lead-lined pans to produce supersaturation without unnecessary crystallization. On controlled cooling, copper sulphate crystals precipitate out from the mother liquor. These are separated by filtration or centrifugation, distilled water is used for washing, and then they are dried to the extent of desired moisture. Lastly, the product is packaged in HDPE bags or drums with anti-moisture protection and good labelling. This process guarantees product integrity while being stored and shipped to agricultural, chemical, and industrial consumers.

_11zon.webp)

Mass Balance and Raw Material Required: The primary raw materials used in the copper sulphate producing plant are copper (97%), sulphuric acid (98%), and water. For a plant producing 1 ton of copper sulphate, 0.27 ton of copper, 0.42 ton of sulphuric acid, and 0.80 ton of water is required.

Machineries Required:

- Sulfuric acid measuring tank

- Elevated tank

- Copper dissolution kettle-reactor

- Reactor pump

- Solid-liquid separator

- Crystallizer with rotation speed changeable

- Mother liquid pool

- Support

- Submerged pump

- Anticorrosive Pump

- Temperature Gauge

- Waste Liquid Tank

- Electric Hoist

- Hosting Container

- Finished Product weighing machine

- Cold water pump

- Reserve Tank

- Electrical Panel

- Centrifugal machine (Including the bags)

- Sunning net tank

- Pipeline, tools, valves, acids valves, oil paints

- Shovel

- Plastic bag packing machine

- Analysis medical instruments

- Densimeter

- Thermometer

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

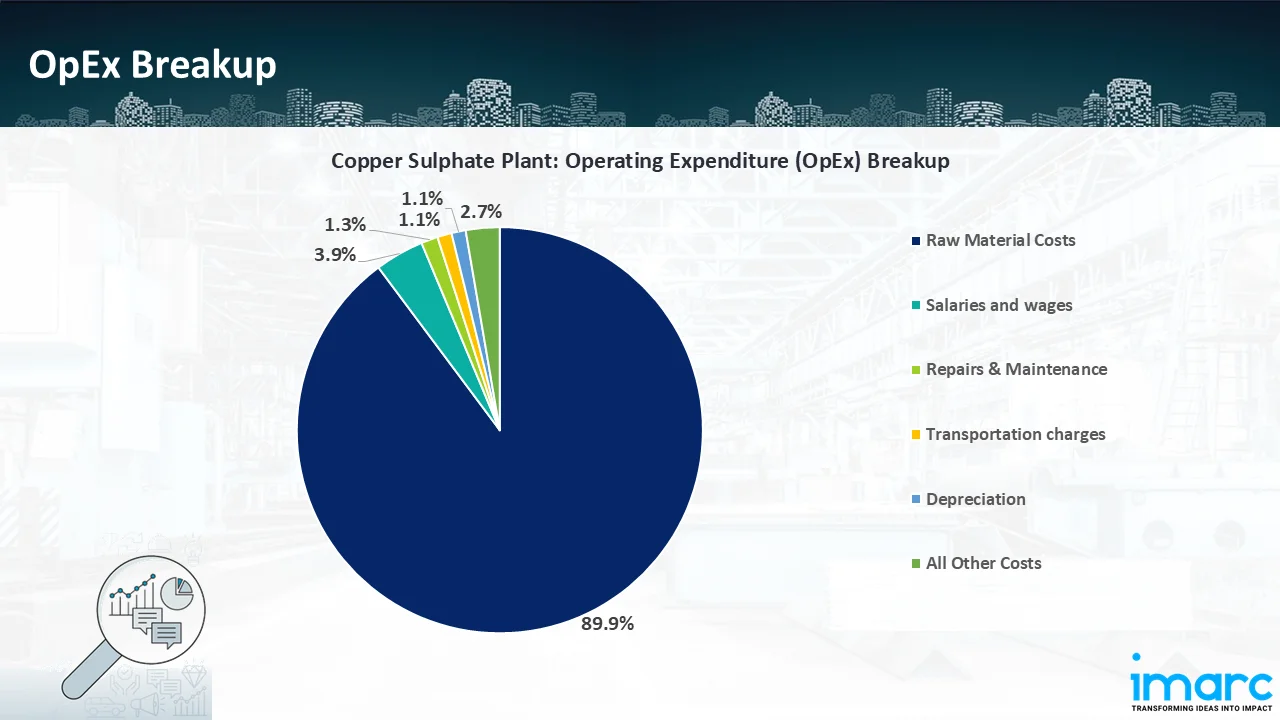

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

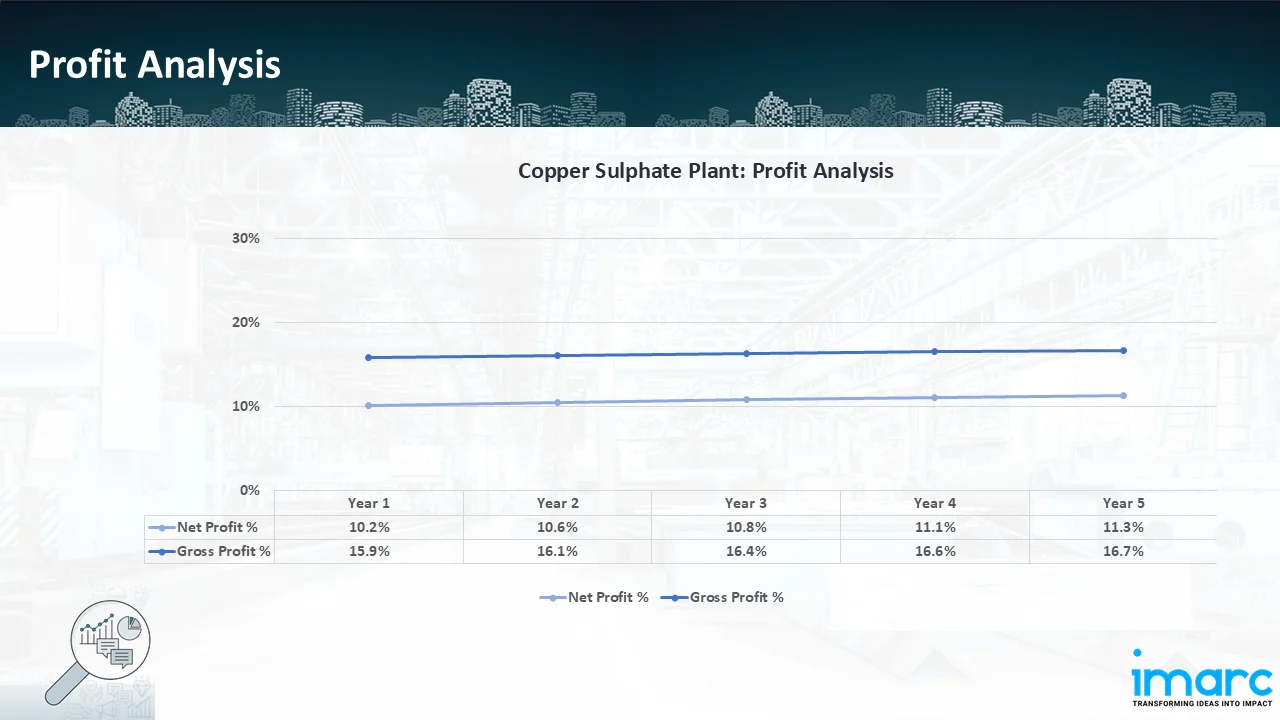

- Profitability Analysis Year on Year Basis: The proposed copper sulphate plant, with a capacity of 10,000 tons of copper sulphate annually, achieved an impressive revenue of US$ 21.7 Million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 15.9% to 16.7% by year 5, and net profit rises from 10.2% to 11.3%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the copper sulphate manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 10,000 tons of copper sulphate annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In September 2025, one of the biggest copper recyclers in the world and a major supplier of non-ferrous metals, Aurubis AG, formally signed a €200 million investment loan agreement with the European Investment Bank (EIB) today. The five-year financing will help Aurubis invest in two key projects: increasing copper refining at its facility in Bulgaria and increasing metal recycling and environmental protection at its facility in Hamburg.

- In November 2024, Tartana Minerals Limited reports that a significant cargo of 150 tonnes was finished last week at its Copper Sulphate unit. The product was sold to one of the biggest mining operations in the Northern Territory through Kanins International, the company's 100% offtake partner.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104