Pan Masala Manufacturing Cost Analysis: From Aroma to Revenue

What is Pan Masala?

Pan masala is a ready-to-use chewing mixture that is traditionally used as a mouth freshener as well as a digestive aid and is of South Asian origin. It is prepared by mixing different components such as areca nut, catechu, slaked lime, spices, flavoring agents, sweet agents, and aroma agents in specific proportions. It is usually packed ready for use and is different from the betel quid variant that is prepared by using fresh betel leaves. Contemporary formulations of pan masala aim to achieve consistency, shelf life, and standardized flavor so that it can be mass-produced and marketed.

Key Applications Across Industries:

The use of pan masala is mainly driven by the need to please the oral cavity, to refresh oneself, or to feel relieved and comfortable in the digestive tract. It was traditionally used as an aid to digest the food intake and to relieve the oral cavity from any foul smell due to the presence of certain aromas added to its composition. It is a practice to offer pan masala to guests in the South Asian subcontinent, as it is a social custom.

In modern market conditions, pan masala is packaged as an FMGC product and consumed as an efficient and portable product with an extended shelf life. Pan masala is used as a non-alcoholic stimulant by some adults, who find stimulation from the sensory inputs of taste and olfaction. Pan masala is marketed as an 'everyday lifestyle' product where multiple flavors, sweetness levels, and 'super-premium' mixes are provided to consumers as an offering to meet all sorts of consumer demands and meet the demands of both 'tradition' and 'youth' segment consumers.

Apart from being consumed directly, the process of manufacturing pan masala has applications in export-oriented categories of ethnic foods and cultural products. In certain applications, variants of pan masala containing non-have or ‘plain’ pan masala, which are non-stimulating, can be used as mouth fresheners, broadening the application base into more consumer-oriented domains. Pan masala is used as a high-rotation item in small format stores because people tend to repurchase pan masala repeatedly.

What the Expert Says: Market Overview & Growth Drivers

The Indian pan masala market reached a value of INR 48,455.9 Crore in 2025. According to IMARC Group, the market is projected to reach INR 67,034.8 Crore by 2034, at a projected CAGR of 3.51% during 2026-2034. The principal driving factors for the global pan masala market are the historical acceptance and integration of pan masala within South Asian cultures, demography, diversification, and the increasing distribution channel reach. The most important driving force behind the increasing adoption of pan masala is its historical acceptance within South Asian cultures, where it is deeply imbibed within hospitality traditions.

Another factor that supports the growth of the market is the increasing trend of urbanization. This is because the more hectic lifestyle of city dwellers is increasingly demanding ready-to-eat and packaged foodstuffs. This characteristic of pan masala, which is ready to consume and has durable packaging, meets the needs of the new lifestyle. Additionally, there are new and differentiated varieties of pan masala that come in different packaging.

Global migration patterns and the subsequent rise in the South Asian diaspora have increased the international demand. Pan masala is becoming more accessible through ethnic retail stores and import-availability channels in other regions like the Middle East, North America, Europe, and the Southeast Asia regions. This helps the company in increasing exports and manufacturing for brand expansion.

Marketing and brand positioning also factor into the popularity of these vapes. Many vapes have been marketed well with good brand recognition and endorsement by celebrities and have a widespread presence in the market, and this has contributed to their popularity and recall. Improvements in manufacturing technology have also resulted in enhanced product quality and have contributed to their scale production.

Despite facing regulatory challenges in certain markets, the players have been able to adapt through compliance-driven innovation, different product forms, and geographically spreading out. With rising disposable income in emerging markets and the demand for traditional consumer goods, pan masala is a robust category worldwide, sustained by its relevance, convenience, and innovation.

Case Study on Cost Model of Pan Masala Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale pan masala manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed pan masala manufacturing plant in India. This plant is designed to manufacture 800 tons of pan masala annually.

Manufacturing Process: The pan masala-manufacturing processes consist of various stages of controlled sourcing, processing, blending, flavoring, and packaging aimed at ensuring production that is consistent, hygienic, and stable. The production process begins with the sourcing of major raw materials like areca nut, catechu, slaked lime, spices, sweeteners, and permitted flavoring substances. Areca nuts are cleaned of impurities and then dried to low moisture content for ease of preservation. The resulting dried product is mechanically cut or ground into precise sizes depending on the texture of the final pan masala product. Catechu and other solid ingredients are prepared and sieved for uniformity. Additionally, other raw materials like sugar and slaked lime are prepared and sieved for uniformity. After individual ingredient preparation, the constituents are processed via automatic or semi-automatic blending processes. Blending follows strict formulae aimed at maintaining consistency in taste, aroma, and texture. Liquid flavoring ingredients, aromas, and sweetening agents are applied either by spraying or compounding into the dried proportion under specified processes that regulate their dispersion and formation of lumps. Moisture content is closely watched during blending processes because high moisture content may compromise shelf life and product stability. The resulting blend pan masala is then submitted for quality checking procedures such as visual checking, particle size testing, and checking for any adulteration. In modern plants, metal detectors and microbiologically safe processing are incorporated simultaneously, keeping in mind food safety parameters. The processed material is then moved to automatic packaging machines and packaged in sachets, pouches, tin containers, or jars maintained at a guaranteed safe setting. Packaging is done using material that resists moisture and aroma damage. The final packaged material is then coded, labeled, and packed in a dry setting.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

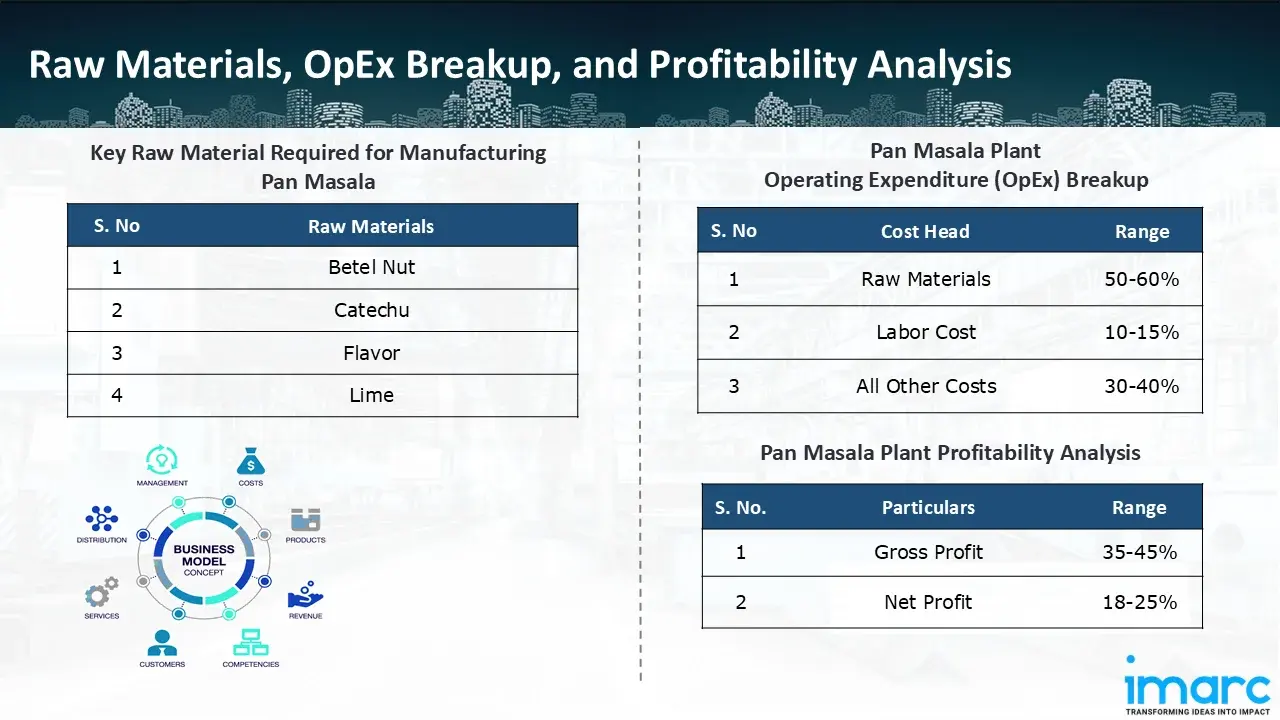

The basic raw materials required for pan masala manufacturing include:

- Betel Nut

- Catechu

- Flavor

- Lime

Machine Section or Lines Required:

- Roasting

- Cutting

- Mixing

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in pan masala manufacturing plant ranges between 50-60%, labor cost ranges between 10% to 15%, and all other costs ranges between 30-40% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 35-45%, and net profit lie between the range of 18-25% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the pan masala manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 800 tons of pan masala annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In December 2025, the Health Security and National Security Cess Bill, 2025 was passed by the Rajya Sabha of India, following a debate in which members of the opposition claimed that the bill violated state sovereignty.

- In June 2024, Aayush Tobaccofree Herbal Pan Masala & Gutka, a ground-breaking product intended to transform the chewing habits of India's 27.49 crore Gutka and Pan Masala users, was unveiled by Aayush Wellness Limited.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104