Egg Powder Cost Model: From Fresh Eggs to Powder

What is Egg Powder?

Egg powder is a type of dehydrated product prepared from whole eggs, egg whites, or egg yolks, using a controlled drying process that removes moisture content while preserving the natural nutrients, flavor, and functional properties in fresh eggs. Originally developed to extend the shelf life of eggs, it was also meant to be convenient and easily transportable for food manufacturing, catering, and military or outdoor purposes.

Key Applications Across Industries:

Powders based on this generally come in three forms: whole egg powder, egg yolk powder, and egg albumen or white powder, each with its applications industrially and gastronomically. The whole egg powder finds common applications in bakery products, sauces, pasta, and ready-to-eat meals. This form of protein might be said to be good enough to function as an emulsifier and binder. Yolk powder is rich in lecithin and thus finds its application as a natural emulsifier in mayonnaise, salad dressings, and confectionery. Egg white powder enjoys a special status due to its foaming and gelling properties and, therefore, finds important applications in preparing meringues and desserts, apart from sports nutrition. Egg powder production ensures a shelf life of 12–24 months without refrigeration, hence addressing the logistical and storage challenges in the global supply chain of food. The dehydration process, usually by spray drying, maintains protein quality and reduces microbial contamination to the barest minimum to ensure food safety and consistency. Egg powder is very easy to reconstitute, has high nutritional value, and therefore is more cost-effective than fresh eggs. The stable nature of egg powder reduces food wastage, allows for bulk transportation, and enables the food processing sector to place greater emphasis on standardized and scalable ingredients. From a humble, esoteric preservation technique, egg powder has evolved to become the mainstay of contemporary food manufacturing, balancing convenience with nutrition and functionality.

Key Applications Across Industries:

Powders based on this generally come in three forms: whole egg powder, egg yolk powder, and egg albumen or white powder, each with its applications industrially and gastronomically. The whole egg powder finds common applications in bakery products, sauces, pasta, and ready-to-eat meals. This form of protein might be said to be good enough to function as an emulsifier and binder. Yolk powder is rich in lecithin and thus finds its application as a natural emulsifier in mayonnaise, salad dressings, and confectionery. Egg white powder enjoys a special status due to its foaming and gelling properties and, therefore, finds important applications in preparing meringues and desserts, apart from sports nutrition. Egg powder production ensures a shelf life of 12–24 months without refrigeration, hence addressing the logistical and storage challenges in the global supply chain of food. The dehydration process, usually by spray drying, maintains protein quality and reduces microbial contamination to the barest minimum to ensure food safety and consistency. Egg powder is very easy to reconstitute, has high nutritional value, and therefore is more cost-effective than fresh eggs. The stable nature of egg powder reduces food wastage, allows for bulk transportation, and enables the food processing sector to place greater emphasis on standardized and scalable ingredients. From a humble, esoteric preservation technique, egg powder has evolved to become the mainstay of contemporary food manufacturing, balancing convenience with nutrition and functionality.

The global egg powder market reached a value of USD 2.02 Billion in 2024. According to IMARC Group, the market is projected to reach USD 2.84 Billion by 2033, at a projected CAGR of 3.69% during 2025-2033. The main factors driving growth in the egg powder market across the world are changes in the pattern of food consumption, the demand for industrial efficiency, and reasons related to nutrition. One of the strongest drivers is the expansion of the processed and convenience food industry, wherein egg powder finds increasing application as a functional ingredient in bakery, confectionery, ready meals, and nutritional supplements. Its ability to provide consistency in flavor, texture, and performance makes it ideal for large-scale food production where uniformity and shelf stability are essential. This also results in increased adoption, especially in emerging markets with limited cold-chain infrastructure, for long-shelf-life and easily transportable ingredients. Other important drivers include increasing worldwide interest in protein-rich and nutrient-dense diets. With its high protein content and complete amino acid profile, egg powder is in agreement with current consumer trends for healthier and high-performance food. This has been one of the main reasons for its use in sports nutrition, dietary supplements, and meal replacements. Additionally, egg powder is increasingly preferred in the foodservice and bakery industry over shell eggs for reasons including lower risk of contamination, reduced handling, and lower storage costs. Technological improvements in spray drying and pasteurization have also enhanced product quality, color retention, and solubility, thus widening its industrial value. Sustainability acts as another catalyst in emerging markets. Egg powder diminishes food waste and carbon footprint associated with refrigerated transport, therefore aligning with eco-conscious manufacturing trends. Besides, urbanization and the growing e-commerce-driven packaged foods marketplace have widened the application scope of egg powder into instant mixes, sauces, and desserts. Collectively, these factors-efficiency in production, convenience, health awareness, and technological innovation-are spearheading global demand and positioning egg powder as a vital component in the evolving landscape of processed and functional food manufacturing.

Case Study on Cost Model of Egg Powder Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale egg powder manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed egg powder manufacturing plant in India. This plant is designed to manufacture 400 tons of egg powder annually.

Manufacturing Process: The manufacturing process of egg powder is a closely controlled industrial process for converting fresh eggs into a stable, long-lasting powder that retains their nutritional and functional qualities. It begins with the selection and cleaning of high-quality eggs, which undergo washing, sanitizing, and crack checks for food safety. After cleaning, the eggs are broken by automated machines that further separate the contents from the shells. Depending on the type of product, the liquid might be processed as whole egg, egg white, or egg yolk. Filtration removes remaining shell fragments and membranes from the separated liquid eggs to assure uniformity and purity. The next critical step in the process is pasteurization, where the liquid egg is heated to a controlled temperature, normally between 60°-65°C, to eliminate pathogenic microorganisms such as Salmonella without denaturing the proteins. Following pasteurization, the liquid is homogenized to ensure consistent texture and prevent separation of components. The treated liquid then enters the spray drying chamber, which is the heart of egg powder production. Here, the liquid is atomized into fine droplets with the help of high-pressure nozzles and exposed to hot air at around 160–180°C. The rapid evaporation of moisture converts these droplets into a fine, dry powder almost instantly, with the functional and nutritional properties preserved in the egg. After drying, the powder is cooled, sieved, and assayed for moisture content, microbial safety, and solubility. Packaging in airtight, moisture-proof containers protects this product from spoilage and promotes shelf stability. The resulting egg powder is lightweight and easy to store; it reconstitutes readily with water, making it ideal in food manufacturing, baking, and nutritional formulation.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

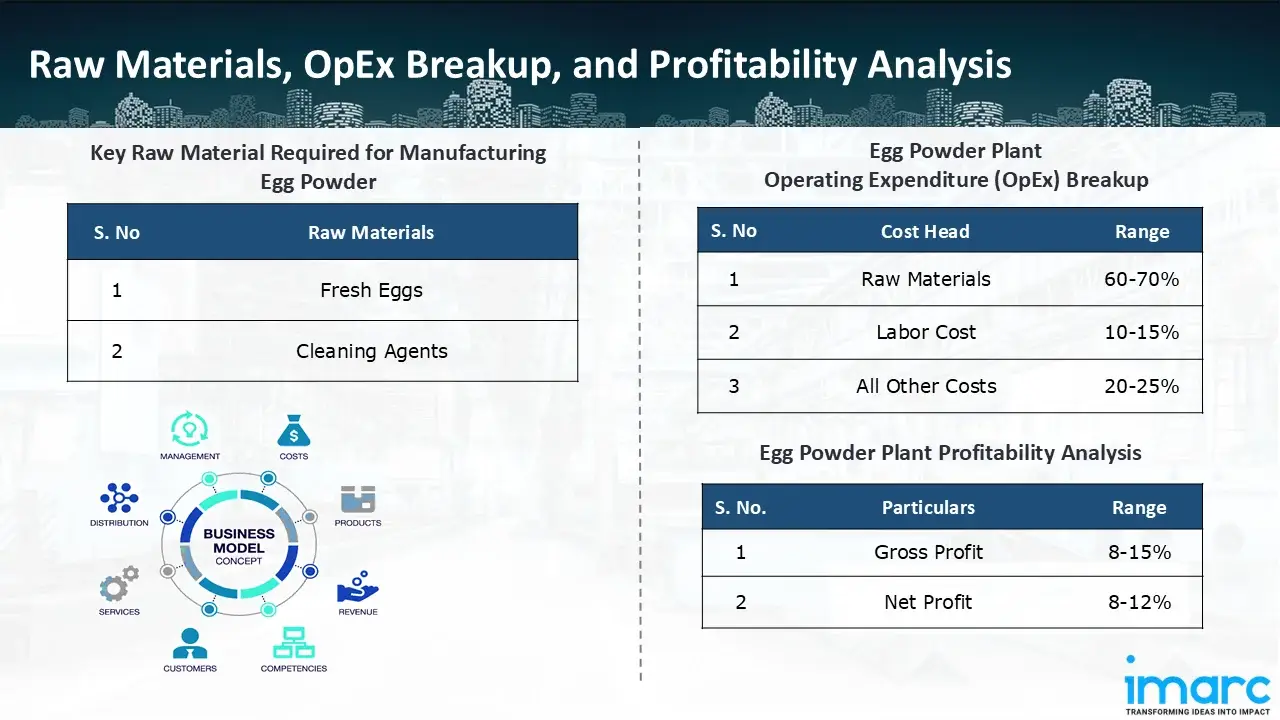

The basic raw materials required for egg powder manufacturing include:

- Fresh Eggs

- Cleaning Agents

Machineries Required:

- Egg Breaking & Separation

- Pasteurization

- Spray Drying

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in egg powder manufacturing plant ranges between 60-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 20-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 8-15%, and net profit lie between the range of 8-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the egg powder manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 400 tons of egg powder annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In April 2025, Ovo Farm India is expanding the egg value chain by opening a state-of-the-art egg processing unit in Balangir, Odisha. The plant started commercial production in mid-April, and it hopes to supply products to markets in the Far East, Southeast Asia, and the Middle East.

- In March 2024, Ovobel Foods purchased the assets of the ‘Egg Powder Processing Unit’ of Bestovo Foods, having its operational facilities in Achar Thimmapur Village, Irakalgad Hobli, Koppal Taluk and District in the State of Karnataka at a cost of Rs 9 crore, for cash.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104