Paint Brushes Manufacturing Cost Analysis: Crafting Precision

What are Paint Brushes?

Paint brushes are hand-operated applicator tools, designed and manufactured with great precision, utilizing the capabilities of these tools to apply, spread, and manage liquid paint, along with other forms of paint such as varnishes, stains, lacquers, and surface finishes, onto a desired surface. Paint brushes are commonly manufactured using a series of components, including a handle, a ferrule, and natural or man-made hairs, or a combination of these two. They are also manufactured and designed with different shapes and sizes, according to the viscosity and texture of the paint.

Key Applications Across Industries:

Paint brush sets have found widespread usage in the area of construction and manufacturing because of their precision and versatility. They are also an essential part of the construction industry and play a crucial role in the application of wall paints and primers. They have a variety of brush types like flat brushes, angle brushes, sash brushes, and round brushes, that cater to different surfaces like dry walls, wood surfaces, metal surfaces, and surfaces of masonry work done by painters during the course of their business operations.

Industrial application of the paint brushes is for the application of protective coating, anticorrosion coats, adhesives, lubricants, and other specialized finishes on machinery parts, pipelines, automotive parts, and manufactured metal products. The paint brushes have applications where touch-up painting is needed or where the area is inaccessible for roller or spray application. Woodwork and furniture industries utilize brushes for the application of stains, varnishes, lacquers, and clear coatings.

Another prominent market where these brushes are applied is in artistic and creative sectors. Artists, illustrators, and craftsmen require fine detail brushes to paint canvas, murals, signage, art, and restoration. Special brushes are also applied in automotive painting, yacht painting, do-it-yourself home improvements, and maintaining infrastructure. Moreover, brushes are also involved in special applications like fire retardant coating applications, waterproofing compounds, and applying epoxy resins. The multifunctionality of these brushes ensures their constant demand among professionals and consumers.

What the Expert Says: Market Overview & Growth Drivers

The global paint brushes market reached a value of USD 4.31 Billion in 2024. According to IMARC Group, the market is projected to reach USD 6.46 Billion by 2033, at a projected CAGR of 4.9% during 2025-2033. The paint brushes market is fueled by construction, innovation, and changing consumer behavior. The major driving force is the steady rise in construction activity, whether it is residential, commercial, or infrastructure, occurring worldwide. New constructions, renovations, or maintenance jobs create a steady stream of demand for painting tools, although painting brushes are always essential, irrespective of the development of roller painting or spray-painting tools. Urbanization, especially in developing countries, drives new constructions.

Growth in the industrial manufacturing sector also drives the demand for the product. It has applications in the auto, aircraft, shipbuilding, metal fabrication, and construction equipment industries for the application of coating through the use of the brushes to apply paint or protective coatings. The brushes are very cheap and ideal even in industries that are highly automated.

Consumer-related factors also have an important role here. In fact, the growing DIY phenomenon around the world, facilitated by home improvement retailers and online content, has spurred demand for user-friendly, relatively inexpensive painting tools. Paint brushes are commonly thought of as entry-level tools among DIY enthusiasts because of their simplicity and relatively low price. On the professional segment, there is growing demand for improved brushes incorporating better filament technology and solvent resistance. Product developments serve as a reinforcement factor. Manufacturers are working on developing synthetic filaments imitating natural bristles, with improved paint pick-up, less dripping, and better durability for water- and solvent-based paints. Government norms on environment-friendly low VOC & water-based paints also trigger requirements for suitable paintbrushes.

Finally, replacement demand is strong because of wear and tear, cleaning limitations, and hygiene requirements in professional applications. Demand associated with new construction work, industry requirements for maintenance work, participation in do-it-yourself projects, and continuous developments in paint brush making sustains positive growth in paint brush production around the world.

Case Study on Cost Model of Paint Brushes Manufacturing Plant:

Objective:

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale paint brushes manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed paint brushes manufacturing plant in India. This plant is designed to manufacture 2 million units of paint brushes annually.

Manufacturing Process: Paint brush manufacturing entails an array of processes pertaining to the preparation of materials, manufacture of parts, assembly, and testing to end-use to manufacture functional painting applicators of optimal performance and durability. The process begins with raw material selection, whereby manufacturers extract natural bristle brush materials from hog hair or man-made materials from nylon, polyester, and polyblend materials. The materials are cleaned and sorted according to thickness and elasticity and cut to different desired sizes according to the brush grades. Simultaneously, handles made from wood, plastics, and composite materials are produced by machining, injection molding, and other shaping methods and painted and varnished for enhanced gripping and durability properties. After preparing the material, the filament bundles are laid out following a brush pattern, such as flat, angled, round, or special shapes. These bundles are placed in a metal ferrule, which can be made from aluminum, stainless steel, or brass. The filament is retained inside the ferrule using epoxy adhesives, staples, or crimped metal bands so as to hold it firmly in place when in use. The ferrule is mounted on the handle by pressing it on or through adhesives. Once mounted, it is shaped and cut to get a uniform bristle arrangement at the tip points. Quality control inspections are done for filament retention strength, alignment, balance of the handle, and finish. Brushes can then go through a series of processes that involve washing, drying, and grooming. Branding and packaging follow, and all these processes help complete the production of the brushes. While manufacturing brushes, more attention is now being focused on automation for filament positioning and assembly. However, craftsmanship is now also gaining prominence for high-quality and professional-grade brushes.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

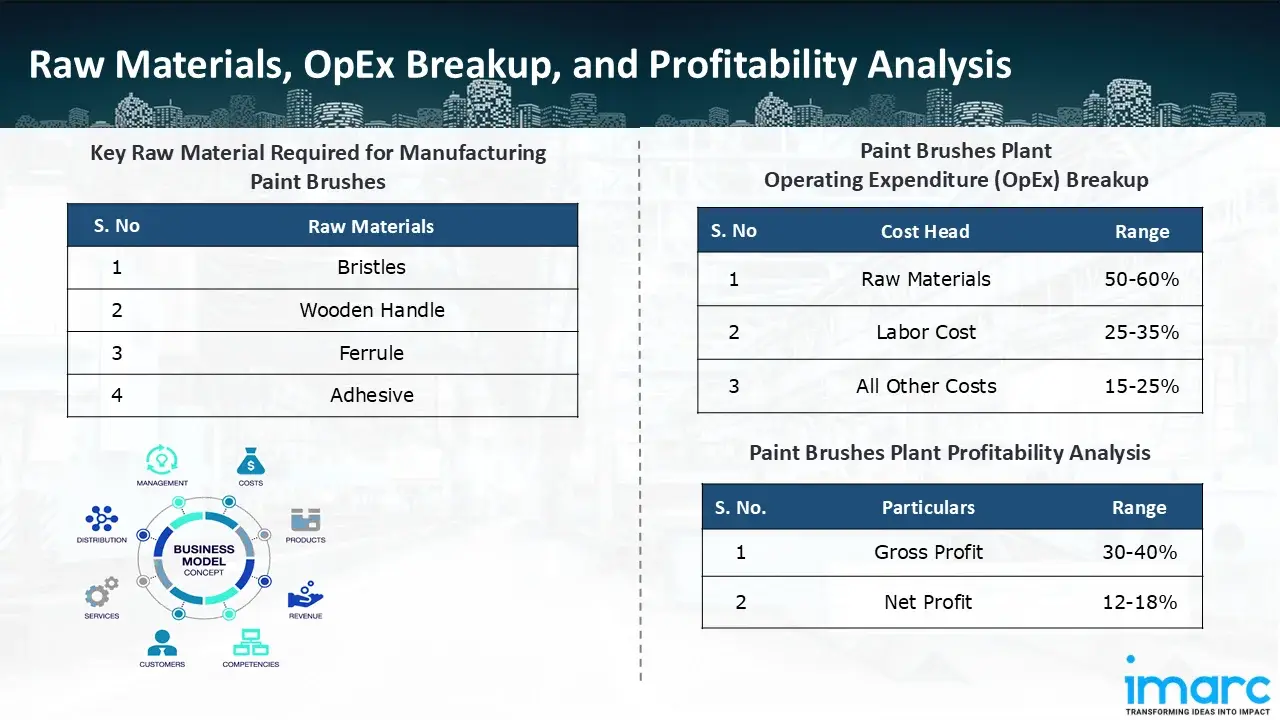

The basic raw materials required for paint brushes manufacturing include:

- Bristles

- Wooden Handle

- Ferrule

- Adhesive

Machine Section or Lines Required:

- Bristle Setting

- Handle Fitting

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in paint brushes manufacturing plant ranges between 50-60%, labor cost ranges between 25% to 35%, and all other costs ranges between 15-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 12-18% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the paint brushes manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 2 million units of paint brushes annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In March 2025, Mr. LongArm, a significant player in the development and production of telescoping extension poles and accessories for more than 67 years, has sold its assets to Gordon Brush Mfg. Co., Inc. Mr. LongArm will continue to operate in the company's current manufacturing facility in Greenwood, Missouri, which is close to Kansas City.

- In September 2024, the assets of Valley Brush Corporation, located in Abbotsford, British Columbia, were recently purchased by Felton Brushes Limited. Founded in 1933, Felton Brushes Limited is a privately held company. The organisation works with numerous industries whose manufacturing processes depend heavily on domestic premium quality.

- In July 2024, Gordon Brush Mfg. Co., Inc. declared that it acquired the assets of Dorden & Company, Inc. and Michigan Brush Manufacturing Company in Detroit, Michigan. The company will immediately relocate all of its operations and manufacturing to Gordon Brush's 183,000 square foot facility in the City of Industry, California.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104