UPVC Windows Manufacturing Cost Analysis: Built for Insulation, Priced for Scale

What is UPVC Windows?

UPVC windows refer to window frames and window assemblies manufactured from ‘unplasticized polyvinyl chloride,’ which is a relatively rigid and strong thermoplastic substance. While PVC is a flexible material that requires the addition of a softening substance called a plasticizer to be formed into a durable performance material, PVC window frames and UPVC window assemblies, for instance, do not display such requirements due to the presence of unplasticizers, a component of the material that provides enhanced strength, stability, and resistance to the elements such as UV radiation, moisture, and temperature changes. While the PVC material may exhibit warping, corroding, and decaying properties in such environments, UPVC window frames do not in any way display such properties.

Key Applications Across Industries:

The UPVC Windows are used extensively in residential, commercial, and institutional spaces to provide natural daylight, ventilation, and environmental comfort. They substitute the wooden frame that is commonly used in residential spaces to provide longer life, ease of maintenance, and comfort. They can be used in bedrooms, living spaces, kitchens, and bathrooms as they resist moisture and corrosion, which otherwise deteriorates the window frame and finish. For multifamily residential spaces, UPVC windows are popular because of their thermal performance and lower lifecycle costs.

In commercial spaces like offices, schools, and hospitals, UPVC windows play a vital role in meeting comfort and energy efficiency requirements. The insulating characteristics of UPVC material contribute greatly to minimizing energy consumption and enhancing comfort levels inside buildings. Not only this, but these windows are also available in different styles, such as casement, sliding, and fixed, making them a versatile product for meeting different requirements. UPVC window systems are also used for building facades and curtain walls where modules are used for sealing purposes and integration with other building equipment like blinds is a must.

The industrial and special use sector involves items such as greenhouses, clean rooms, or sound booths, where the chemical, humidity, and exposure resistances of uPVC make it an ideal material of choice. uPCV windows can offer double- or triple-glazed configurations, low-e coating, and gas fills to offer the highest level of thermal insulation for even extreme environments. It can also be a prime choice for retro-fitting old structures, thus providing a state-of-the-art solution without any need for modifications to the existing building structure.

What the Expert Says: Market Overview & Growth Drivers

The global UPVC doors and windows market reached a value of USD 38.20 Billion in 2024. According to IMARC Group, the market is projected to reach USD 58.20 Billion by 2033, at a projected CAGR of 4.8% during 2025-2033.

The UPVC windows market is driven by a number of factors that are structural, economic, as well as performance based. One of the more prominent factors is that of increasing focus on sustainability and energy efficiency. The UPVC materials are known to reduce heat loss and thereby minimize energy use for heating and cooling. Moreover, these windows are known for providing greater energy efficiency through their multi-chamber, tightly sealed designs that are also conducive to high-performance glazing materials with high specification requirements for new designs as well as renovations.

City population growth and housing construction developments, particularly within developing countries, represent significant demand sources. Fast turnover in housing stock supply, coupled with increasing income levels for the middle class and mortgage finance availability, drives demand for products offering attributes such as durability, minimal maintenance requirements, and cost-effectiveness. UPVC window products represent a product range fitting these attributes.

UPVC systems have advantages due to lifecycle cost considerations and operational efficiency for the long-term in commercial and institutional sectors where there are alternatives to traditional materials like wood or aluminum. Reduced maintenance requirements-no repainting or corrosion control-and extended service life equate to lower total cost of ownership, which is a key decision factor for facility managers and procurement professionals.

Other factors contributing to market growth include technological advances in UPVC compounding, profile design, and hardware integration. Indeed, modern UPVC formulations have much better impact resistance, fire performance, and recyclability, therefore broadening their circle of use cases and allowing them to meet even the most stringent regulatory standards. Smaller lots and customization options in modular manufacturing enable fabricators to provide tailored solutions for the most complicated architectural facades, further improving market attractiveness.

Another emerging factor is those aspects that relate to environmental concerns. Although UPVC is produced from petroleum products, recent improvements in recycling strategies and facilities can ensure that sustainability is now one of the positive consequences. Therefore, UPVC manufacturers that can point to enhanced recycled content in products and recycling opportunities at the end of their lifecycle can reap the benefits of enhanced competition. Overall, these considerations include energy codes, urban growth patterns, cost considerations, performance innovations, and sustainability.

Case Study on Cost Model of UPVC Windows Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale UPVC windows manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed UPVC windows manufacturing plant in India. This plant is designed to manufacture 200,000 square meters of UPVC windows annually.

Manufacturing Process: The manufacturing process of UPVC windows involves intricate processes that include material compounding, profile manufacture, profile fabrication, glazing, and the assembly of UPVC window systems. Manufacture starts by compounding the resin blend, which involves mixing unplasticized PVC resin, stabilizers, impact modifiers, pigments, and additives to give the UPVC resin high strength, long-lasting resistance to ultraviolet light, and durability in harsh weather conditions.

The compounded material is then introduced to extrusion lines where it undergoes a process that heats it and pushes it through special designed dies to produce multi-chamber UPVC profiles. Such chambers facilitate insulations. The profiles are then cooled down and adjusted to precise lengths. Steel or galvanized materials are then introduced into specific chambers to enhance structural stiffness for large window frames.

Then there is the fabrication process, where profiles have to be cut to appropriate sizes as dictated by the design of the window. The corner welding process is carried out by using heat welding machines. This process also involves cleaning of the cut ends to ensure that they have the required polish. Other fixtures, like hinges, locks, handles, and gaskets, are also included.

The glazing process follows, where individual or double/triple glass is installed inside the fabricated frames. The glass units are held in place by glazing beads. Rubber gaskets are then used to ensure proper insulation, thereby preventing any leakage of air/water. Energy or sound-proof glass can be provided as required.

Finally, the finished windows are subject to a quality check with regards to dimension, weld integrity, hardware functionality, and sealing efficiency. The ones that meet product standards are cleaned, packed, and transported out of the establishment. Modern-day UPVC window fabrication is all about mechanized production, uniformity, and customization to fulfill appropriate building needs for residential as well as commercial building projects.

Explore in-depth findings for this market, Request Sample

Raw Material Required:

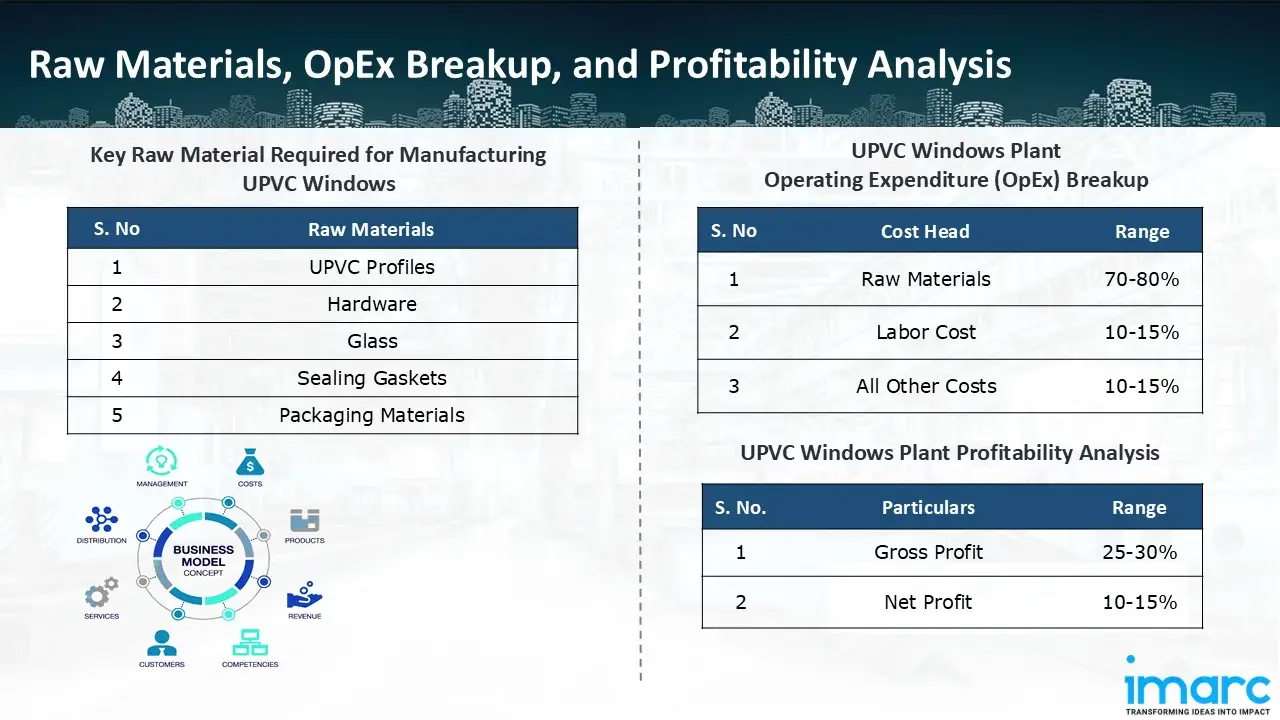

The basic raw materials required for UPVC windows manufacturing include:

- UPVC Profiles

- Hardware

- Glass

- Sealing Gaskets

- Packaging Materials

Machine Section or Lines Required:

- Cutting

- Welding

- Cleaning

- Assembly

- Glazing

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in UPVC windows manufacturing plant ranges between 70-80%, labor cost ranges between 10% to 15%, and all other costs ranges between 10-15% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-30%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the UPVC windows manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 200,000 square meters of UPVC windows annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2025, SBM Gold, an important producer of high-density polyethene (HDPE) pipes with headquarters in North Bengal, announced the formal debut of uPVC doors and windows, marking a major diversification of its product line. This represents a significant shift for the business, which now sees itself as a provider of complete building solutions for India's expanding infrastructure market.

- In February 2025, VEKA has successfully acquired full control of its joint venture in India, indicating increased direct investment in the rapidly expanding Indian construction industry as well as better localised supply and marketing for profiles and systems.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104