Glass Fiber Reinforced Polymer (GFRP) Rebar and Mesh Cost Model: Reinforcing the Future

_11zon.webp)

What is Glass Fiber Reinforced Polymer (GFRP) Rebar and Mesh?

Glass Fiber Reinforced Polymer (GFRP) rebar and mesh are composite materials developed to be used in place of the conventional steel reinforcement in concrete structures. They consist of continuous glass fibers dispersed within a polymeric resin matrix, most commonly epoxy, vinyl ester, or polyester.

Key Applications Across Industries:

The synergy between the tensile strength of glass fiber and the corrosion inhibition properties of polymers produces reinforcement products that are light weight, corrosion-free, and extremely durable. GFRP rebar and mesh have high tensile strength-to-weight ratios, electromagnetic neutrality, and alkali resistance, which make them ideal for use in long-term infrastructure. They are produced using pultrusion, filament winding, or molding to form the rebars, and surface treatments for better bonding with concrete. They are used in wide-ranging applications from bridges, highways, and tunnels to marine structures, industrial floors, and precast concrete products, where long-term durability and low maintenance are essential. Economic benefits incorporate lower lifecycle expenses as a result of less frequent repair requirements and convenient handling. Increased global focus on sustainable building translates to greater use of GFRP products for increased service life, minimized carbon footprint, and lower logistics. Future prospects are bright, with increasing adoption in intelligent infrastructure and climate-resilient constructions globally.

What the Expert Says: Market Overview & Growth Drivers

The United States Glass Fiber Reinforced Polymer (GFRP) rebar and mesh market size reached USD 210.6 Million in 2024. According to IMARC Group, the market is projected to reach USD 561.6 Million by 2033, at a CAGR of 11.3% during 2025-2033.

The GFRP rebar and mesh industry is driven primarily by the growing demand for corrosion-resistant substitutes for steel reinforcement, particularly in marine and coastal structures where chloride-induced corrosion is a key challenge. Growing investment in infrastructure, notably in bridges, highways, and urban public transport networks, is a key growth driver. The lightweight nature and handling ease minimize construction time and cost to support greater uptake. Another force behind the growth is the increasing demand for non-magnetic reinforcement in hospitals, defense buildings, and laboratories. Future trends involve the coupling of GFRP with intelligent sensing technologies to facilitate structural health monitoring. The next five years will witness high growth rates in developing economies, especially Asia-Pacific and the Middle East, where infrastructure projects are large-scale in nature. Advantages are high strength, lower lifecycle costs, and meeting tight sustainability targets. Challenges are in increased initial cost compared to steel and limited contractor familiarity. Sustainability drivers are favorable, with GFRP greatly reducing repair time and energy-consumptive steel use. The market is reacting with standardization of design codes, increased production capacity, and collaborations between composite producers and construction companies to drive adoption.

Case Study on Cost Model of Glass Fiber Reinforced Polymer (GFRP) Rebar and Mesh Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale Glass Fiber Reinforced Polymer (GFRP) rebar and mesh manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed Glass Fiber Reinforced Polymer (GFRP) rebar and mesh manufacturing plant in United States. This plant is designed to produce 2,722 tons of Glass Fiber Reinforced Polymer (GFRP) rebar and 144 tons of Glass Fiber Reinforced Polymer (GFRP) mesh annually.

Manufacturing Process: The process of Glass Fiber Reinforced Polymer (GFRP) rebar and mesh production is almost the same, differing in how they are shaped. The process starts with the preparation and creeling of fibers, where glass fibers are stretched in a continuous form (rovings) and aligned under tension for stability and strength. Fibers are then passed through a bath of resin, which saturates them with thermosetting polymers like epoxy, polyester, or vinyl ester, often supplemented with additives. In rebars, the resin-coated fibers pass through a preforming die which compresses them to the required profile, and in mesh, fibers are positioned in perpendicular grids with automated machines and bonded at intersections. The impregnated material proceeds to be cured in a heated die or oven, where heat is controlled to trigger polymerization that rigidizes the composite in its final form. After curing, products are subjected to surface treatments like sand coating or helical wrapping to improve concrete bonding. Cut rebars or mesh are cured and then cut to exact lengths or panel sizes, occasionally coiled into rolls for shipping. Stringent quality control testing confirms ASTM and ACI compliance, assessing strength, size, and bonding characteristics. Lastly, rebars and mesh are wrapped for protection and stored in pallets or wrapping and labeled for traceability to be shipped to construction sites.

_11zon.webp)

Mass Balance and Raw Material Required: The primary raw materials used in the Glass Fiber Reinforced Polymer (GFRP) rebar and mesh producing plant are glass fiber rovings, epoxy resin, and additives and hardeners. For a plant producing 1 ton of Glass Fiber Reinforced Polymer (GFRP) rebar, 0.720 ton of glass fiber rovings, 0.260 ton of epoxy resin, and 0.057 ton of additives and hardeners is required. For a plant producing 1 ton of Glass Fiber Reinforced Polymer (GFRP) mesh, 0.680 ton of glass fiber rovings, 0.290 ton of epoxy resin, and 0.059 ton of additives and hardeners is required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

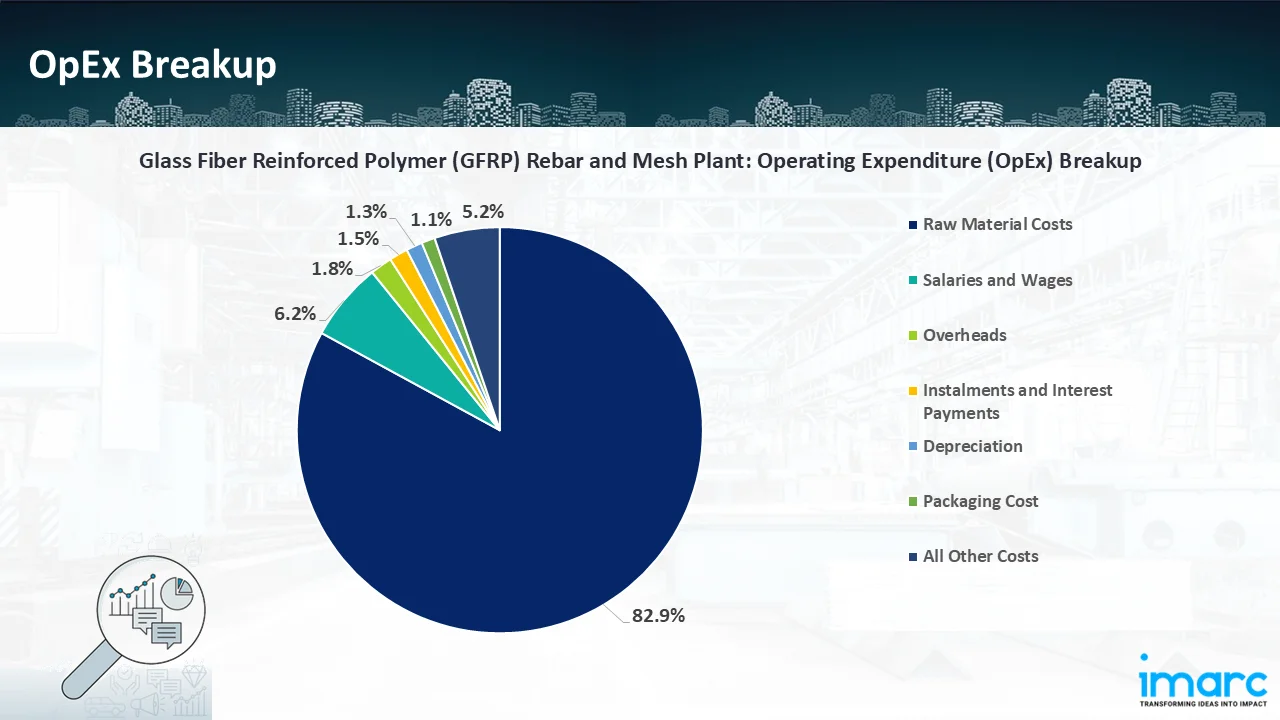

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

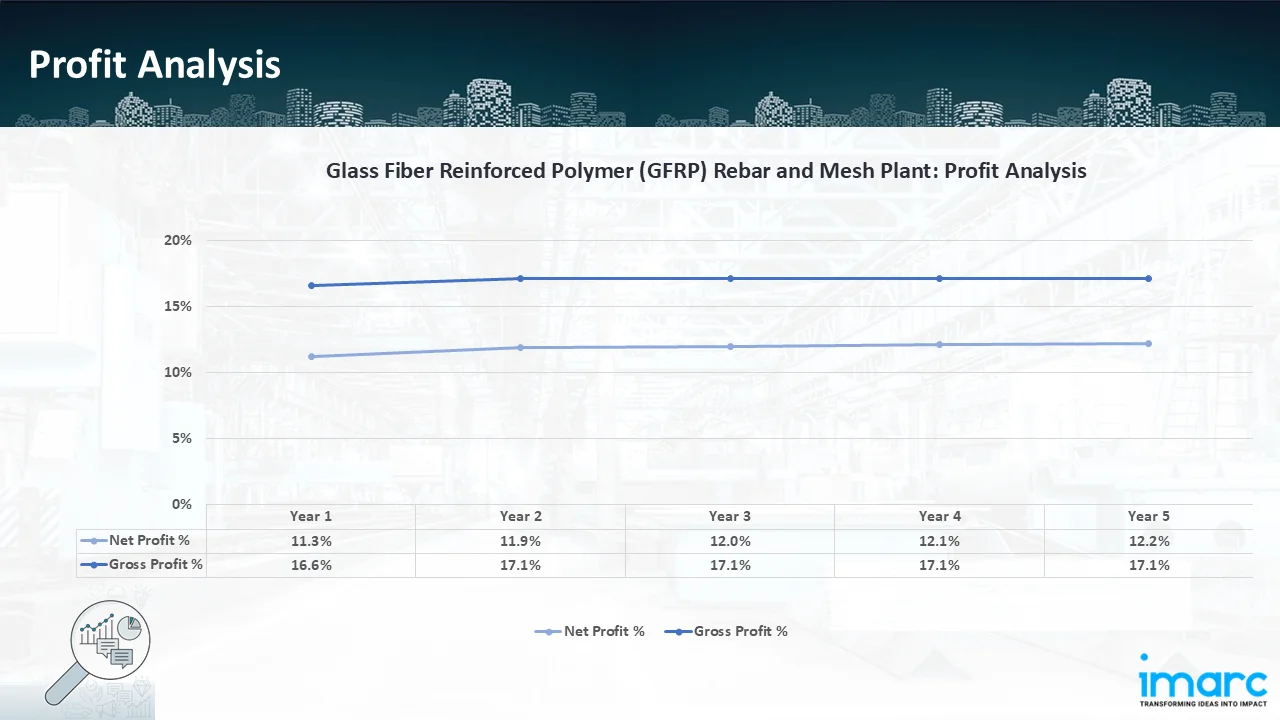

- Profitability Analysis Year on Year Basis: The proposed Glass Fiber Reinforced Polymer (GFRP) rebar and mesh plant, with a capacity of 2,722 tons of Glass Fiber Reinforced Polymer (GFRP) rebar and 144 tons of Glass Fiber Reinforced Polymer (GFRP) mesh annually, achieved an impressive revenue of US$ 10.4 Million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 16.6% to 17.1% by year 5, and net profit rises from 11.3% to 12.2%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the Glass Fiber Reinforced Polymer (GFRP) rebar and mesh manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 2,722 tons of Glass Fiber Reinforced Polymer (GFRP) rebar and 144 tons of Glass Fiber Reinforced Polymer (GFRP) mesh annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In November 2024, the first production facility of its sort in South Africa has been opened by GFRP Tech, a company that manufactures and supplies glass fibre reinforced polymer (GFRP) products. For the first time on the African continent, GFRP Rebar, GFRP Mesh, and GFRP Bends will be produced at the new plant in Linbro Park, Gauteng.

- In July 2024, in order to become a dominant force in the market, Jindal Advanced Materials announced that it intends to fivefold its FRP rebar manufacturing capacity to 1 lakh metric tonnes by the upcoming fiscal year. It can currently produce about 18,000 tonnes from two factories in Haryana, at Pathredi and Hisar.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104