Aluminum Extrusion Cost Model: Making Scrap Worthy

What is Aluminum Extrusion?

Aluminum extrusion is a versatile metal forming process whereby aluminum billets are pushed through a shaped die to create long profiles with the same cross-section. Through this process, manufacturers can create intricate shapes that balance strength, lightweight characteristics, and beauty, making it a cornerstone of several industries.

Key Applications Across Industries:

The procedure starts with aluminum billets, which are usually pre-heated to 400–500°C, and are then extruded through steel dies under pressure. The extruded portions are then cooled, stretched to eliminate distortions, cut to specified lengths, and in some cases, heat-treated to obtain desired mechanical characteristics. Extrusion may be done in two major types: direct extrusion, where the ram and billet are in the same direction, and indirect extrusion, in which the die is in motion as the billet is fixed. Such a manufacturing process is very efficient and low on material waste, making it desirable for mass production. The natural properties of aluminum are lightweight, high strength-to-weight ratio, good corrosion resistance, and recyclability, supplement the benefits of extrusion. Products produced include door and window frames, curtain walls, structural elements, car body components, aerospace fittings, heat sinks, and railway lines. In addition, the possibility of anodizing, coating, or machining extruded aluminum improves its strength and appearance, further broadening its uses across industries. As the focus on eco-friendly manufacturing and lightweight materials continues to grow, aluminum extrusion remains a vital component of contemporary industrial design and engineering.

What the Expert Says: Market Overview & Growth Drivers

The global aluminum extrusion market size reached USD 97.4 Billion in 2024. According to IMARC Group, the market is projected to reach USD 185.2 Billion by 2033, at a projected CAGR of 7.4% during 2025-2033.

The construction industry is one of the major drivers, with extruded aluminum extensively used for doors, windows, curtain walls, roofing systems, and modular buildings because it is durable and offers design flexibility. Automotive and aerospace are also significant contributors, with manufacturers moving towards lighter materials to improve fuel efficiency, lower emissions, and comply with strict regulatory requirements. As electric vehicles (EVs) become popular across the world, aluminum extrusions find more application in battery enclosures, crash management systems, and lightweight body structures. Another major stimulus is the solar and wind renewable energy industry, where extruded profiles play an important part in panel frames, supports, and mounting systems. In addition, industrial applications like machinery, heat exchangers, and power transmission systems are dependent on extruded aluminum due to its excellent thermal and electrical conductivity. At the macroeconomic level, demand is also complemented by urbanization and infrastructure growth in Asia-Pacific and the Middle East, with governments pouring money into building, transportation, and energy initiatives. Moreover, the aluminum extrusion is also facilitated by the world's transition towards circular economy practices, as aluminum can be 100% recycled without diminishing its properties, fitting into sustainability and cost-effectiveness objectives. Increased uptake of sophisticated extrusion technologies, automation, and value-added services like surface finishing and fabrication also fuel market growth. Collectively, these factors are generating strong global demand for aluminum extrusion by end-use industries.

Case Study on Cost Model of Aluminum Extrusion Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale aluminum extrusion manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed aluminum extrusion manufacturing plant in India. This plant is designed to produce 40,000 tons of aluminum extrusion (billets) annually.

Manufacturing Flow: Production of aluminum extrusion is an orderly process converting solid aluminum billets into long, continuous profiles with specified cross-sectional shapes. The production process starts with billet preparation, whereby the aluminum billets in cylindrical form are trimmed to the correct size and heated to approximately 400–500°C to soften the metal enough without melting it. The heated billet is then placed into an extrusion press, where it is pushed by a hydraulic ram through a steel die for extrusion that is used to create the profile shape. When the billet is pushed through the die under tremendous pressure, the aluminum conforms to the opening of the die and comes out in a long, steady section. The extruded aluminum is subsequently cooled quickly, usually by air or water sprays, in order to preserve dimensional stability and mechanical integrity. Following cooling, the extruded sections are stretched straight to compensate for twisting or bending caused by extrusion, so they are straight and even. The extrusions are subsequently cut into lengths as needed, based on their end-use applications. In cases where products need to have added strength, hardness, or resistance to corrosion, the sections are subjected to heat treatment (tempering) for the attainment of desired mechanical characteristics. Lastly, extrusions can be subjected to surface finishing operations like anodizing, powder coating, or painting to add durability and eye appeal. Sophisticated operations can further involve machining or fabricating in order to produce custom parts. This combination of forming, strengthening, and finishing makes aluminum extrusion a cost-efficient, versatile, and environmentally friendly manufacturing method employed across industries including construction, automotive, aerospace, electronics, and renewable energy.

Get a Tailored Feasibility Report for Your Project Request Sample

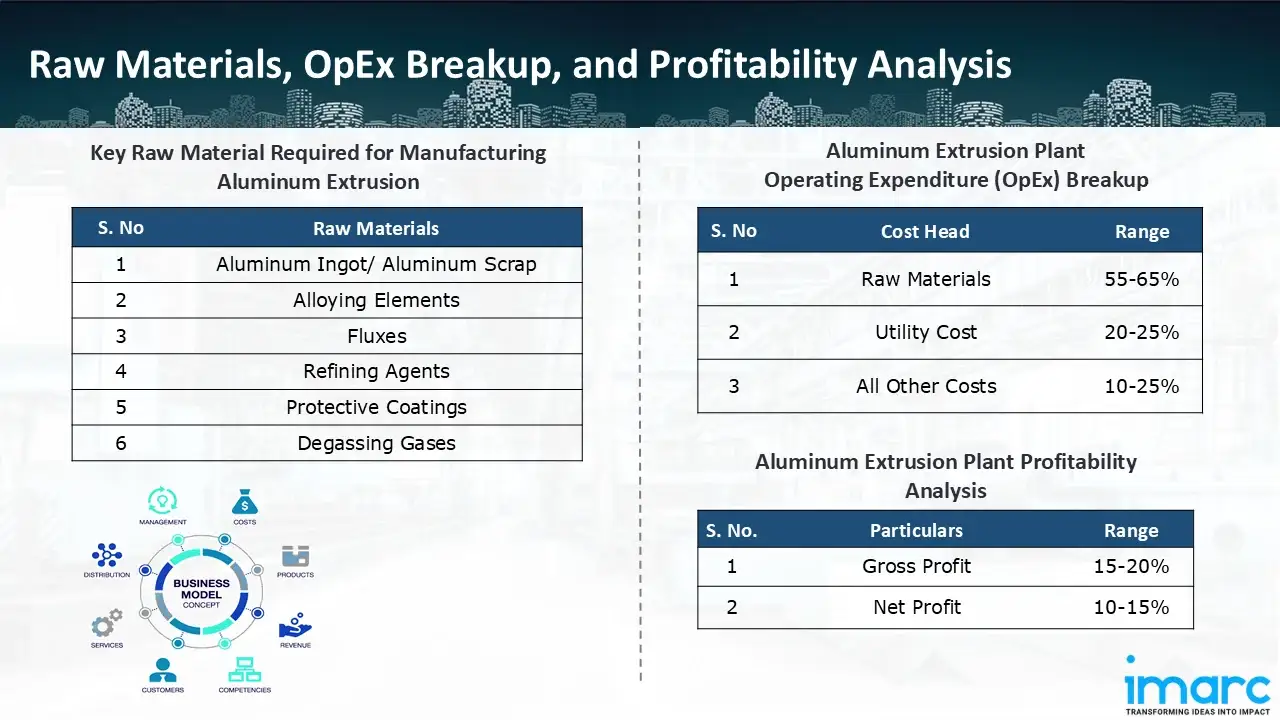

Raw Material Required:

The basic raw materials required for aluminum extrusion (billets) manufacturing include:

- Aluminum Ingot/Aluminum Scrap

- Alloying Elements

- Fluxes

- Refining Agents

- Protective Coatings

- Degassing Gasses

Machineries Required:

- Scrap Sorting Line

- Overhead Cranes

- Cutting System

- Conveyors

- Charging Systems

- Reverberatory Furnace/ Rotary Furnace / Induction Furnace / Holding Furnace

- Rotary Degassing Units

- Flux Injection System

- Ceramic Foam Filter Box

- DC Casting Table with Water-Cooled Moulds

- Metal Launder System

- Water Cooling & Recirculation System

- Casting Pit with Hydraulic Lift

- Billet Saws (Circular or Band Saws)

- Automated Billet Handling Conveyors

- Billet Stacking/Transfer Systems

- Homogenization Furnaces (Batch or Continuous)

- Cooling Beds / Forced-Air Coolers

- Billet Scalper

- Surface Brushing/Polishing Unit

- Ultrasonic/Electromagnetic Inspection System

- Automated Weighing & Marking Machine

- Packaging & Strapping Systems

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in an aluminum extrusion manufacturing plant ranges between 55-65%, utility cost ranges between 20% to 25%, and all other costs ranges between 10-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the aluminum extrusion manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 40,000 tons of aluminum extrusion (billets) annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale Manufacturing ventures.

Latest News and Developments:

- In September 2025, Vedanta Aluminium, announced the introduction of its new 5-inch billets at ALUMEX India 2025, the country's first conference and exhibition devoted to aluminum extrusion. The 5-inch billets, which were created in response to the growing need for precisely manufactured aluminum, are intended for vital uses in a variety of sectors, including building and construction, automotive, aircraft, and HVAC.

- In September 2025, Fastmarkets, a prominent PRA, announced the establishment of a domestic pricing reference for premium aluminum billets in Brazil. The introduction of this benchmark by Fastmarkets, the first PRA in Brazil, is a significant step forward as the nation's aluminum market becomes more independent and prominent in the global supply chain.

- In July 2025, EGA Spectro Alloys, began manufacturing at its cutting-edge aluminum recycling facility in Rosemount, Minnesota. Following the completion of the new expansion, billet will be produced and sold under EGA's recycled product brand RevivAL by the top Midwest-based manufacturer of recycled aluminum alloys.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish Manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104