Paper Plates Manufacturing Cost Analysis: Disposable Dining, Durable Margins

What are Paper Plates?

Paper plates are disposable food containers, also referred to as tableware, and are made mostly from paperboard, pulp, and materials that are derived from fibers. These plates are designed to be convenient, hygienic, and easy to handle while being moisture and grease-proof, making them ideal for packing different food varieties, ranging from dry foods to moist and greasy food items. Paper plates are also coated with different materials to boost moisture and grease resistance and to enhance strength. Paper plates are preferably one-use and can be recycled, making them a popular substitute for regular and plastic plates.

Key Applications Across Industries:

Paper plates find wide applications in food services, as well as in households, institutional settings, and food events. Paper plates are mainly used in households as a way of preparing food informally, during picnics, parties, and other functions. They can also be used outdoors since they are very portable and can be disposed of once they are through with. They are very lightweight as well.

In the food industry, paper plates are widely used in fast food restaurants, food carts, and catering businesses to package snacks, entrees, desserts, and side dishes. Paper plates can withstand hot meals, sauces, and oils. Paper plates are also commonly used when hosting major events such as marriage ceremonies, festivals, seminars, and sports. The main reason for using paper plates in such events is for convenience and hygiene.

Institutional usage may involve a school, hospital, office, or community center, which uses paper plates instead of reusable dishes, thus ensuring that the distribution of food is managed. Paper plates can also be used in eateries, which allow users to access fast food easily, hence no need for much infrastructure setup.

Apart from serving as a food container, paper plates are also used as a material for arts and crafts and educational purposes. There are specialty plates made with extra strength and features like partitions and designs being used in high-end catering events. Paper plates ensure various consumption occasions through convenience, affordability, and disposability.

What the Expert Says: Market Overview & Growth Drivers

The global paper cups and paper plates market reached a value of USD 120.5 Billion in 2024. According to IMARC Group, the market is projected to reach USD 141.8 Billion by 2033, at a projected CAGR of 1.8% during 2025-2033. Across the global paper plates market, factors such as change in consumption patterns, growth in the foodservice market, and an increasing focus on sustainability and hygiene are driving the market. An important factor driving the paper plates market is the steady increase in the number of quick-service restaurants, street foods, and catering businesses across the world.

With an increasing number of people moving to urban areas and a shortage of time, people are looking for convenient eatables that can be served ready to eat. This has led to an increase in the usage of paper dinner plates, paper platters, or paper plates in general. Issues of hygiene and food safety have played an important role in market development. Paper plates eliminate the risks associated with cross-contamination in food, which may occur with reusable plates. Paper plates thus become an ideal choice for institutions such as schools, hospitals, or public gatherings due to these associated health benefits. Preference by consumers for these product solutions further adds impetus.

Awareness and regulation regarding the environment and plastic disposables act as strong catalysts for growth. Single-use plastic plates have been banned or opposed by many governments and local authorities. Paper plates that can be made from renewable resources and compostable materials appeal to the cause of sustainability and green initiatives. Research and developments in coating processes have made them greasier and are being increasingly accepted in the environment.

Growth from organized retailing and online retailing also helps to propel the market, given that paper plates are widely distributed through supermarkets, convenience stores, as well as online platforms. Product diversification, such as designs with compartments, enhanced durability, and upscale looks, helps to increase usage occasions and attract new consumers. Lifestyle changes, government support, environmental concerns, and technological developments are thus contributing to a steady rise in paper plate production globally.

Case Study on Cost Model of Paper Plates Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale paper plates manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed paper plates manufacturing plant in India. This plant is designed to manufacture 30 million units of paper plates annually.

Manufacturing Process: The manufacturing process for paper plates entails a range of operations aimed at creating lightweights that can be conveniently used as a means for food or other services. These operations start with the choice of materials that may be paperboard or molded pulp produced from virgin or reused papers. For molded pulp production, for instance, wastepaper or fibers from crops are pulped by the action of water. The resulting mixture is purified by removing any impurities present. It is then refined for measurement depending on the required strength. The processed pulp is then packed into forming molds, where the vacuum suction helps to shape the fibers into plates. The excess water is drained, and the plates are then packed into hot presses. The heat and pressure help to dry the plates, stiffen them, and smooth the surface texture. The sheets made from paperboard are die-cut into circular blanks, which are then thermoformed to create depth and stiff edges. Based on their end use, the plates can be treated with some finishes or coatings to enhance resistance to moisture, grease, and heat. Quality control checks are also done to inspect the thickness, size, and strength of the plates. Trimming, piling, inventory, and packaging of the processed plates follow. While processing, it is very essential on the part of the manufacturer to conserve water, energy, and minimize waste, and currently, more and more green products have come into use.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

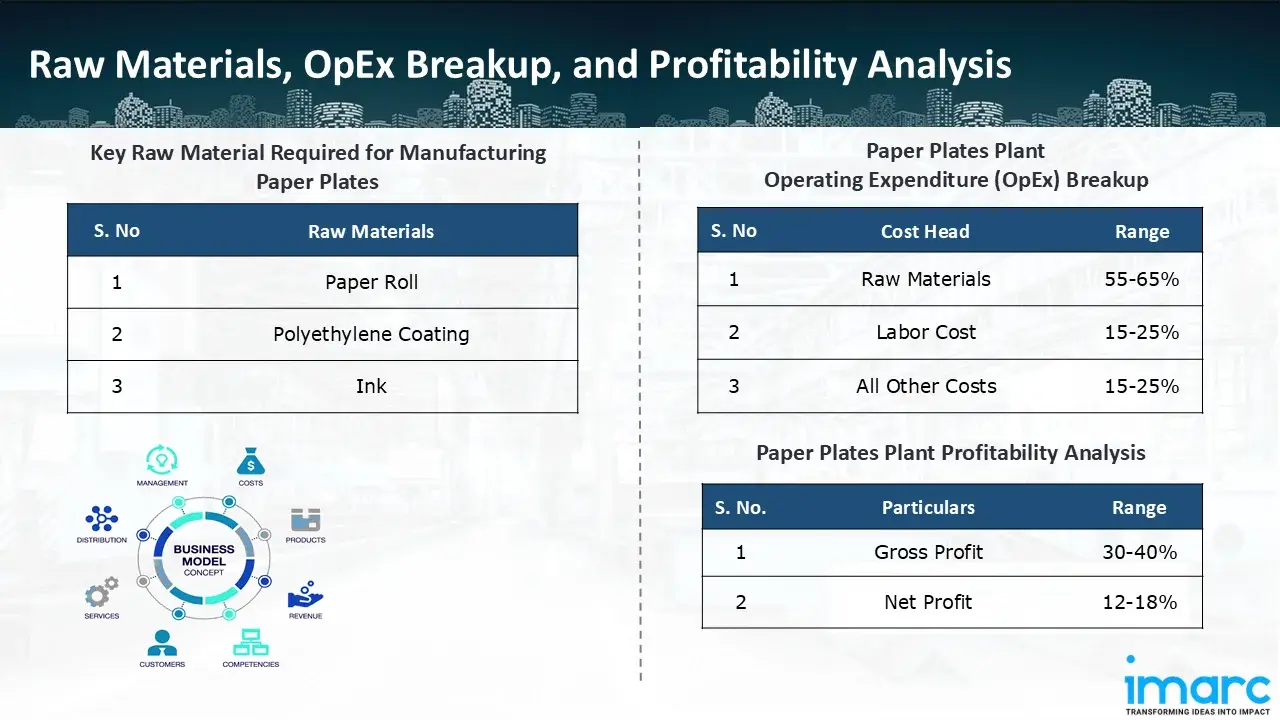

The basic raw materials required for paper plates manufacturing include:

- Paper Roll

- Polyethylene Coating

- Ink

Machine Section or Lines Required:

- Printing

- Cutting

- Forming

- Bottom Sealing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in paper plates manufacturing plant ranges between 55-65%, labor cost ranges between 15% to 25%, and all other costs ranges between 15-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 12-18% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the paper plates manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 30 million units of paper plates annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In September 2025, DuPontTM Cyrel Flexographic Solutions announced that it would be displaying its dedication to quality assurance in India and providing attendees with a first look at its branded DEC 185 flexo plates at IndiaCorr Expo 2025.

- In May 2024, the famous arty cup company SOLO announced SOLO Bold HoldTM, its newest innovation in paper dinnerware. With unmatched strength and durability and the strictest sustainability requirements, this new line of heavyweight paper plates is made to give customers trust without sacrificing quality.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104