Perfume Manufacturing Cost Analysis: The Fragrance Formula

What is Perfume?

Perfume is a scented liquid composition that contains a mixture of fragrance chemicals, essential oils, aroma chemicals, fixatives, and solvents that are formulated for a pleasing and distinct fragrance emission upon application on human skin or on objects. The perfume fragrance formulation involves a carefully calculated method of blending fragrance chemicals to provide a harmonious fragrance character that systematically develops over time, usually characterized by a top, middle, and base note fragrance. Perfumes are formulated in different concentration strengths, known by names such as parfum, eau de parfum, and eau de toilette. It is however important to note that perfume encompasses chemistry, art, and branding.

Key Applications Across Industries:

The main use of perfume as a product is related to its use as a personal care or beauty aid for the improvement of personal fragrance, confidence, and appeal. The perfumes are used by consumers as a direct application to the skin or clothes. Various types of perfumes depending on the desired use or conditions are chosen and therefore perfumes not only exhibit high product differentiation but also high customization. Additionally, perfumes have an important role to play as a lifestyle product.

In addition to direct personal usage, perfumes find extensive use in consumer products related to perfumes. Luxury fragrances are utilized in high-end personal care products like deodorants, body sprays, lotions, and hair mists with the intention of creating multi-sensory fragrant experiences. In retail settings, ambient fragrances are leveraged with the aim of creating brand identity fragrances that have an influence on consumer perception and experience in hospitality spaces like hotels, restaurants, and upmarket retail spaces. Perfume fragrances are leveraged to influence perception.

Fragrance compositions are also used in limited editions, co-branding, and design fragrances as extensions of fashion brands. As cultural and ritualistic products, perfumes are used in celebrations, worship, and other rituals in regions around the globe. Another set of perfumes are niche/artisan fragrances, which are targeted at consumers seeking uniqueness, natural ingredients, and their own personal fragrances. As such, perfumes are used not as mere fragrances, but as culture, as emotion, and as commercial products.

What the Expert Says: Market Overview & Growth Drivers

The global perfume market reached a value of USD 41.6 Billion in 2025. According to IMARC Group, the market is projected to reach USD 64.3 Billion by 2034, at a projected CAGR of 4.72% during 2026-2034. The market for perfumes is influenced by the prevailing lifestyle of the consumer and the rising income levels of the population. Among the most prominent driving factors is the growing awareness of personal grooming and care. The use of perfumes is not considered a luxury or an item to be utilized in celebrations and events but an essential component of a person’s daily care routine.

The growing middle-class population and premiumization trend provide support for increased spending in branded and premium fragrance spending. The demand for emotionally driven consumer goods that provide benefit and expression, which are exclusively met by fragrance, is on the rise. This is driven by offerings that provide benefits in terms of emotional storytelling, endorsement, and influencer campaigns.

Cultural and societal trends play an equally important part in the development of the market. Fragrances are deeply rooted in the culture and custom of perfume use of many places. Globalization has resulted in the enhancement of acceptance and favor for various scents, which has ultimately resulted in the development of the market.

Product innovations continue to play an important role. Innovations in fragrance chemistry, sourcing, and processing allow creation of longer-lasting, skin-friendly, and sustainable fragrances. The growing need for natural, clean, sustainable, and responsibly sourced ingredients has motivated producers of perfumes to innovate new fragrances that appeal to these values. The niche of perfumes, exclusivity, and personalization of scents further encourage innovations.

The rise in organized retailing, online shopping, and travel retail contributes to increased accessibility and global positioning for perfume brands. Online shopping assists in marketing and faster product launches in the market. Additionally, online shopping or travel retail assists in high-end perfume sales free from taxes and duties. Taking everything into consideration, growth in perfume production is backed by various factors such as lifestyle change and innovation in perfume production.

Case Study on Cost Model of Perfume Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale perfume manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed perfume manufacturing plant in India. This plant is designed to manufacture 200 kilo litres of perfume annually.

Manufacturing Process: Perfume manufacturing is a highly controlled, specialized process that involves formulation, aging, filtering, and packaging. Perfume manufacturing basically involves fragrance formulation, where specific mixes of aromatic ingredients like natural essential oils, aroma compounds, and fixatives are proportioned according to a specific formula that determines the character of the fragrance. Perfume concentrates are carefully crafted in specific proportions to ensure that specific amounts of top, middle, and base notes are attained. After that, the final product is ready to be diluted in specific quantities of demineralized water and purified ethanol, depending on the desired strength of the perfume, such as parfum, eau de parfum, and eau de toilette. Next, the perfume mixture is subjected to a process where it is stored in stainless steel tanks for maturation or maceration for quite some time. This process is important since it enables the different ingredients used in the mixture to work in harmony and for their fragrances to fully develop. At this stage, the perfume mixture is then cooled and subjected to filtration. Cooling is important since it enables the mixture to precipitate any insoluble matter, which is then eliminated through filtration. Quality control tests are carried out during the production process to ensure that the perfume has the required fragrance, alcohol concentration, color, stability, and microbiological safety. After that, the perfume is moved to automatic filling machines that fill it into bottles and seal it with either a pump or a cap. The perfume is also labeled and packed. The process strictly follows safety and hygiene standards. Another process carried out during the production of perfume is packaging.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

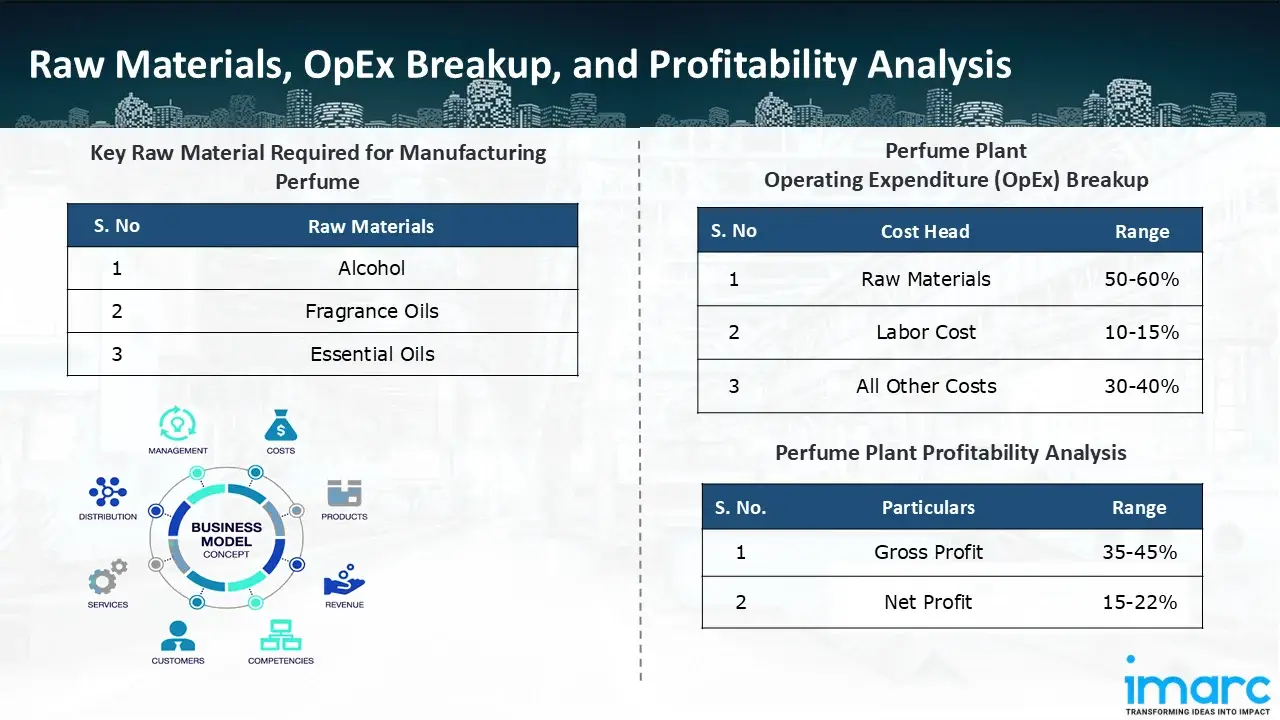

The basic raw materials required for perfume manufacturing include:

- Alcohol

- Fragrance Oils

- Essential Oils

Machine Section or Lines Required:

- Mixing

- Maturation

- Filtration

- Filling

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in perfume manufacturing plant ranges between 50-60%, labor cost ranges between 10% to 15%, and all other costs ranges between 30-40% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 35-45%, and net profit lie between the range of 15-22% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the perfume manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 200 kilo litres of perfume annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In November 2025, L'Oréal is investing €60 million to modernise its Gauchy manufacturing facility, boosting output as the business is ready to add Gucci and Balenciaga scents to its lineup. As the demand for fragrances continues to rise, the investment will strengthen L'Oréal's capacity by enabling the facility in northern France to create up to 200 million perfume bottles yearly.

- In July 2025, Turpaz Industries Ltd. (TASE: TRPZ), a multinational corporation that creates, produces, and sells flavours, fragrances, and speciality fine ingredients, has completed the purchase of a controlling 68.6% in the French fragrance company Attractive Scent SAS for EUR 27.4 million (USD 32.3 million).

- In June 2025, the fragrance company House of Aurae has entered the premium fragrance industry in India and has expanded its product line with a range of body mists, hair mists and fragrances that are intended to provide a customised smell experience.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104