Aluminum Ingots Cost Model: Smelting Costs, Shaping Markets

What is Aluminum Ingots?

Aluminum ingots are standardized raw forms of aluminum that are produced by smelting and refining processes, which act as a basic raw material for downstream industries. The ingots are commonly prepared by refining bauxite ore to alumina through the Bayer process, followed by electrolytic reduction in smelters through the Hall-Héroult process.

Key Applications Across Industries:

The molten aluminum thus produced is cast into ingot shape for transportation convenience, handling, and further processing. Aluminum ingots are also divided into primary ingots, which are directly produced from mine bauxite, and secondary ingots, which are made of recycled aluminum scrap and are receiving growing significance on account of sustainability issues. Ingots are of various purity grades based on the high-purity aluminum ingots are used in electronics, aerospace, and packaging, whereas general-purpose ingots are used in construction, automotive, and machinery. Aluminum's natural characteristics are light weight, corrosion resistance, high conductivity, and ductility, making aluminum ingots a key intermediate in contemporary industrial supply chains. They are further adaptable into sheets, plates, foils, extrusions, castings, and wires. The versatility of aluminum ingots has resulted in their widespread use across end-use industries such as transportation, building and construction, electrical and electronics, consumer goods, and packaging. Being a world-traded commodity, aluminum ingots are strongly dependent on raw material price volatility, energy prices, recycling patterns, and global trade policies.

What the Expert Says: Market Overview & Growth Drivers

The global aluminum ingots market size reached 15.02 Million Tons in 2024. According to IMARC Group, the market is projected to reach 20.83 Million Tons by 2033, at a projected CAGR of 3.3% during 2025-2033. The aluminum ingots market globally is spurred by an interplay of factors that cut across industrial demand, sustainability patterns, and technological progress.

Among the major drivers is the increasing automotive and transport industry, where aluminum ingots are transformed into light-weight parts for cars, aircraft, and rail networks to improve fuel efficiency and lower emissions. The construction sector also plays a major role in driving demand since aluminum ingots are transformed into structural profiles, exterior cladding, and roofing material, taking advantage of the material's toughness and corrosion resistance. The other major driver is the packaging sector, specifically aluminum foils and cans, that heavily depend upon ingot-based manufacturing to cater to the market for green, recyclable packaging materials. Furthermore, the transition towards energy is driving electrical applications' demand for ingots in transmission cables and renewable energy systems due to the better conductivity-to-weight ratio of aluminum. On the demand side, growth is driven by recycling, as secondary ingots of aluminum have cost benefits and lower carbon intensity, supporting global decarbonization goals. Circular economy supportive policies and energy-efficient materials supportive policies from governments are fueling investment in recycling technologies and production of secondary ingots. At the same time, local supply chain growths—e.g., Asian smelter growths, European recycling plants, and North American low-carbon aluminum programs—are restructuring trade flows and pricing. Finally, advances in casting and alloying technology are expanding applications for aluminum ingots in high-performance markets. Together, these elements underpin strong long-term growth opportunities for the global aluminum ingots market.

Case Study on Cost Model of Aluminum Ingots Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale aluminum ingots manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed aluminum ingots manufacturing plant in India. This plant is designed to produce 45,000 tons of aluminum ingots annually.

Manufacturing Flow: The production process of the aluminum ingot entails various crucial steps starting from the recovery of alumina from bauxite ore by the Bayer process. In this process, bauxite is ground, blended with caustic soda, and then exposed to high pressure and temperature to dissolve aluminum oxide, with the impurities remaining as red mud. The alumina (Al2O3) is finally precipitated, washed, and calcined to form a fine white powder that acts as feedstock for smelting. The second stage is the Hall-Héroult electrolytic reduction process in which alumina is dissolved in molten cryolite within large electrolytic cells. A high direct current is imposed through carbon electrodes, reducing alumina to molten aluminum metal, which accumulates at the bottom of the cell. This molten aluminum is then drawn off at regular intervals and put into holding furnaces, where it is refined and alloyed to eliminate such impurities as silicon, iron, and copper. Alloying materials can also be introduced to make the final product conform to the requirements of its end use. After refining, the molten aluminum is poured into ingot molds by direct chill (DC) casting or normal mold casting techniques. Water sprays are used in DC casting to solidify metal quickly and minimize defects, creating uniform ingots that can be processed downstream. The ingots are cooled, extracted from molds, and inspected for quality to ascertain conformity to purity, composition, and mechanical properties industrial standards. Lastly, the ingots are cleaned on the surface, packaged, and shipped to industries like automotive, construction, aerospace, and packaging, where they are melted and processed into a final aluminum product.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

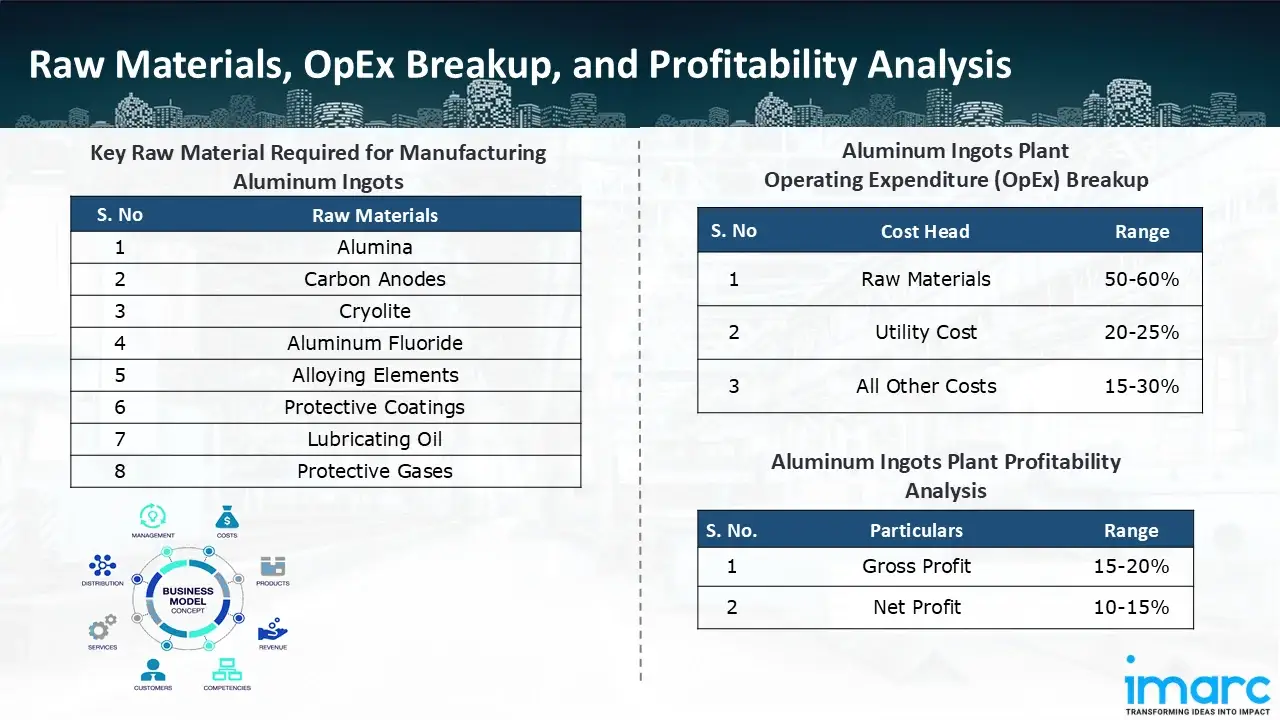

The basic raw materials required for aluminum ingots manufacturing include:

- Alumina

- Carbon Anodes

- Cryolite

- Aluminum Fluoride

- Alloying Elements

- Protective Coatings

- Lubricating Oil

- Protective Gases

Machineries Required:

- Alumina Handling/Silos

- Anode Baking & Rodding System

- Conveyors & Feeders Electrolytic Reduction Cells

- Rectifiers & Busbars (DC Power Supply)

- Anode & Cathode Assemblies

- Fume Collection & Gas Treatment Plant

- Tapping Machines

- Transport Ladles (Insulated Crucibles on Transfer Cars)

- Holding Furnace

- In-Line Degassing Units (Rotary Degasser)

- Ceramic Foam Filters

- Ingot Casting Machine (Tilting / Continuous)

- Water Cooling Sprays

- Ingot Conveyors

- Automated Stacking & Strapping Machines

- Marking Systems

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in an aluminum Ingots manufacturing plant ranges between 50-60%, utility cost ranges between 20% to 25%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the aluminum ingots manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 45,000 tons of aluminum ingots annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In April 2025, the Aditya Birla Group's metals division, Hindalco Industries, has unveiled a major expansion plan that includes a 300,000-ton copper smelter extension at Dahej, a new 850,000-ton alumina refinery, and a 540,000-ton increase in aluminum smelting capacity.

- In September 2024, Hydro installs a new aluminum recycling facility. With an annual capacity of 90,000 tonnes in Hungary. Hydro's new aluminum recycling facility in Szekesfehervar, Hungary, primarily serves the car industry.

- In September 2024, Alcoa announced that it has signed a legally binding agreement with Saudi Arabian Mining Company to buy and subscribe for shares. As part of the arrangement, Alcoa will sell Ma'aden its whole ownership stake of 25.1% in the Ma'aden Joint Venture for about US$ 1.1 billion.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish Manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104