Syringe Manufacturing Cost Analysis: Clean Manufacturing, Clear Costs

_11zon.webp)

What is Syringe?

A syringe is a medical instrument that is used to inject fluids into the body or to withdraw fluids from the body. A syringe usually has a cylindrical body, a plunger that moves inside the body to generate pressure or suction, and a nozzle to which a needle can be attached. Syringes are used to inject a certain amount of fluid into the body, and they come in different sizes, depending on the requirements of the medical field. The syringe has become a crucial instrument in the medical field because it is now disposable and made of plastic.

Key Applications Across Industries:

Syringes have numerous applications in the healthcare sector for a wide range of purposes. The primary application of syringes is for the administration of injectable drugs, such as vaccines, antibiotics, insulin, anesthetics, and biologic agents. In healthcare facilities, syringes are a crucial tool for intravenous, intramuscular, subcutaneous, and intradermal injections.

Syringes are also employed for blood sampling and collection for analysis. In a laboratory and healthcare setting, syringes enable precise transfer and measurement of liquids, reagents, and biological samples. In a surgical and emergency healthcare setting, syringes are employed for washing wounds, emergency drug administration, and contrast agent administration in imaging procedures.

Syringes also have applications in veterinary healthcare for the treatment of animals, administration of vaccines, and collection of biological samples. In pharmaceutical research and development, syringes are employed for dosing in clinical trials, formulation testing, and quality control testing.

Specialized syringes, including prefilled syringes, safety syringes, and insulin syringes, are designed for specific uses to enhance the accuracy of dosing and minimize the risk of needle-stick injuries. Syringes are also used in home healthcare, allowing patients to personally administer drugs for chronic diseases. Their versatility, accuracy, and adaptability make syringes an essential tool in all medical, research, and veterinary applications.

What the Expert Says: Market Overview & Growth Drivers

The global syringe market reached a value of USD 22.57 Billion in 2025. According to IMARC Group, the market is projected to reach USD 41.47 Billion by 2034, at a projected CAGR of 7.0% during 2026-2034.

The syringe market is fueled by basic healthcare requirements and long-term trends. One of the main drivers of the syringe market is the growing number of chronic diseases such as diabetes, cardiovascular diseases, and autoimmune diseases, which require frequent injectable medications. As treatment protocols increasingly involve biologics and injectable medications, the demand for syringes continues to increase.

The growth of vaccination programs around the world is another major driver of the syringe market. Immunization programs, mass vaccination campaigns, and readiness for infectious disease outbreaks all rely heavily on large-scale syringe supplies.

The development of healthcare infrastructure, especially in emerging markets, also helps to fuel market expansion. Investments in hospitals, clinics, diagnostic centers, and primary healthcare infrastructure lead to increased usage of syringes for both treatment and diagnostic purposes. The growing geriatric population in various parts of the world also helps to fuel increased usage of healthcare services, including injectable therapies.

Technological and regulatory considerations also have a significant role to play. The growing need for patient safety has led to the adoption of safety syringes that are designed to prevent reuse and needle-stick injuries. Regulatory norms that favor the use of single-use, sterile medical devices also help to ensure a steady demand for disposable syringes.

The growing need for home healthcare and self-medication also helps to fuel the demand for user-friendly syringe designs. Along with the steady development of new pharmaceuticals, these considerations help to ensure a steady global demand for syringe manufacturing that is not dependent on short-term or cyclical trends.

Case Study on Cost Model of Syringe Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale syringe manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed syringe manufacturing plant in India. This plant is designed to manufacture 100 million pieces of syringe annually.

Manufacturing Process: The production process of syringes is a very controlled and precise process that aims to satisfy strict medical safety and quality requirements. The process starts with raw material preparation, where medical-grade polymers such as polypropylene are chosen for the barrel and plunger because of their clarity, resistance to chemicals, and biocompatibility. Rubber or elastomer materials are processed separately for plunger gaskets to ensure smooth gliding and leak resistance.

The critical parts are produced by injection molding. The barrels, plungers, and needle hubs of syringes are injection-molded in high-precision molds in cleanroom or controlled environments to preserve dimensional precision and surface quality. In the case of syringes with needles already attached, stainless steel needles are produced separately by wire drawing, cutting, grinding, and polishing, followed by siliconization to lower the force of insertion.

Once molded, the parts proceed to assembly processes. The barrels, plungers, gaskets, and needles of syringes are assembled by high-speed automated machines to reduce direct human contact and potential contamination. In the case of safety syringes or special models, other mechanisms such as needle shields or retraction devices are incorporated during this phase.

After the assembly process, the syringes are siliconized to facilitate the movement of the plunger. The syringes are then sterilized through the use of ethylene oxide gas, gamma radiation, or steam, depending on the design of the syringes.

The final process involves inspection and quality control, where the syringes are tested for leakage, size, sterility, and functionality. The syringes that pass the test are then packaged in sterile blister packs or pouches in a cleanroom environment.

Get a Tailored Feasibility Report for Your Project Request Sample

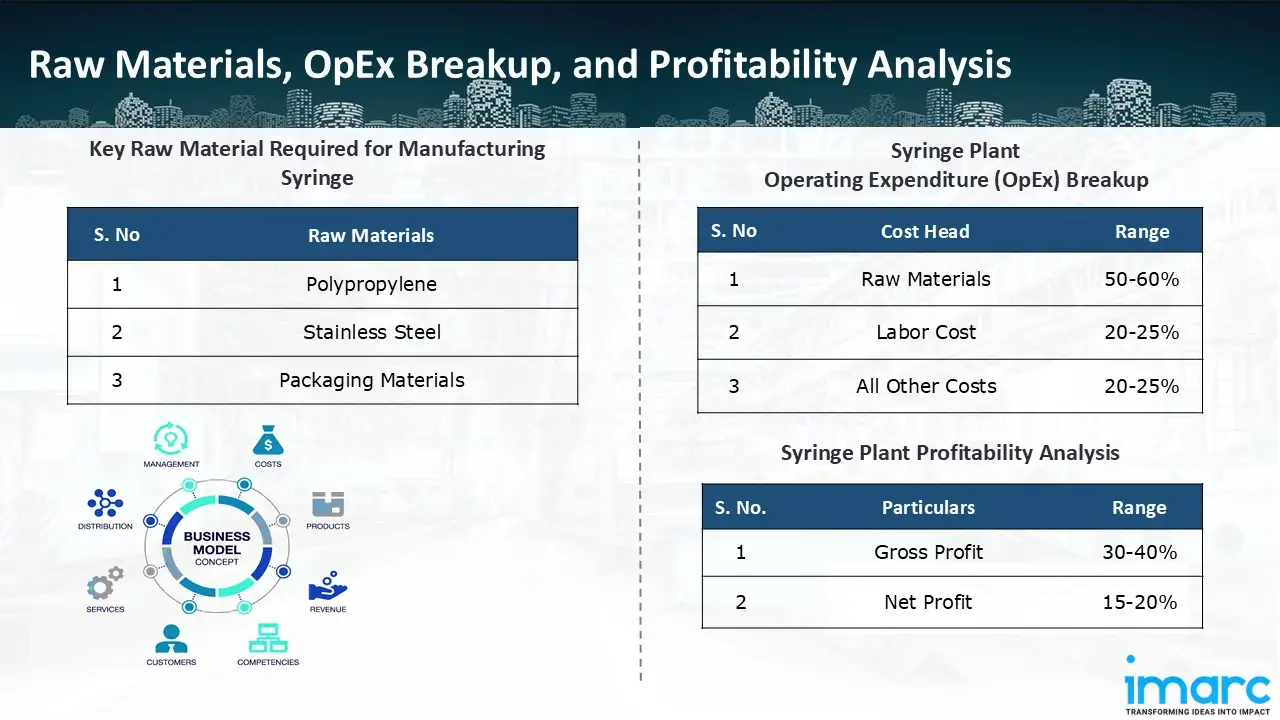

Raw Material Required:

The basic raw materials required for syringe manufacturing include:

- Polypropylene

- Stainless Steel

- Packaging Materials

Machine Section or Lines Required:

- Injection Molding

- Needle Assembly

- Sterilization

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in syringe manufacturing plant ranges between 50-60%, labor cost ranges between 20% to 25%, and all other costs ranges between 20-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 15-20% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the syringe manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 100 million pieces of syringe annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In August 2025, BD (Becton, Dickinson and business), a major global medical technology business, announced plans to invest more than USD 35 million and add about 50 new jobs to expand prefilled flush syringe manufacturing at its Columbus, Neb. facility to strengthen the resiliency of the U.S. health care system.

- In May 2025, Terumo Corporation, a firm that develops containers such as prefilled syringes and drug delivery devices made of materials that are appropriate for the pharmaceutical industry, announced that it has agreed on an acquisition of the drug product (DP) plant in Leverkusen, Germany, owned by WuXi Biologics for 150 million Euro.

- In December 2024, Gerresheimer, a cutting-edge system and solution supplier and worldwide partner for the pharmaceutical, biotech, and cosmetics sectors, is building a new syringe manufacturing hall to increase its production capacity in Skopje, North Macedonia. Gerresheimer has been manufacturing plastic drug delivery systems, diagnostic devices, and medical supplies on about 14,600 square meters since 2019 at this location.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104