Aluminum Powder Cost Model: From Metal to Microns

What is Aluminum Powder?

Aluminum powder is a finely divided metallic aluminum with a wide range of applications in various industries because of its specific physical and chemical properties. It is manufactured by atomization, mechanical grinding, or flake milling of pure aluminium. The powder has high reactivity, low density, high thermal conductivity, and high reflectivity.

Key Applications Across Industries:

Depending on the manufacturing technique, it can exhibit spherical, irregular, or flake-like morphologies, making it suitable for diverse applications. In the metallurgical sector, aluminum powder is used in powder metallurgy to produce lightweight structural components and alloys. In the chemical and pyrotechnic industries, it acts as a critical ingredient in explosives, fireworks, rocket propellants, and thermite reactions due to its high exothermic oxidation behavior. Further, in aerospace and defense applications, aluminum powder is used in solid rocket propellants and energetic commodities. It is also finding growing applications in additive manufacturing (3D printing), coatings, paints, and solar cell pastes. The reflective and corrosion-resistant properties of the powder render it useful for protective and aesthetic purposes as well. At the global level, the world market for aluminum powder is experiencing high technology development, especially in atomization and surface treatment methods, that can increase powder uniformity and performance.

What the Expert Says: Market Overview & Growth Drivers

Concerns about the environment are also influencing contemporary production, as manufacturers seek sustainable and low-carbon powder production. Overall, aluminum powder is a multifunctional material that is poised between conventional metallurgical uses and new high-tech fields due to its balance of lightness, strength, and reactivity. The global aluminum powder market reached a volume of 669,800 Tons in 2024. According to IMARC Group, the market is projected to reach 772,200 Tons by 2033, at a projected CAGR of 1.6% during 2025-2033.

The global market for aluminum powder is mainly fueled by increasing demand from the automotive, aeronautics, and additive manufacturing industries. Lightweight materials are gaining increasing popularity to enhance fuel efficiency and lower carbon emissions, and aluminum powder has an important role to play in manufacturing sophisticated lightweight parts using powder metallurgy and 3D printing. The growth of aerospace and defense industries, especially in the United States, China, and India, has boosted the use of aluminum powder in solid rocket propellants, explosives, and novel energetic materials. The fast uptake of additive manufacturing technologies, where spherical aluminum powders are critical for producing intricate, high-performance components with minimal material waste, is the other key driver.

Aluminum powder has extensive applications in the chemical and construction industries in autoclaved aerated concrete (AAC) manufacturing, paints, and thermite welding, driving demand from industrial development and infrastructure. Moreover, the shift to renewable energy and electric vehicles (EVs) is driving the application of aluminum powder in battery parts, conductive coatings, and energy-saving systems. The market is also spurred by innovation in atomization processes with reduced particle size control and enhanced powder quality for premium applications. Moreover, rising defense budgets, space exploration missions, and the creation of environmentally friendly pyrotechnic compositions are driving the market forward. On the demand side, leading manufacturers are incorporating sustainable production methods, including recycling aluminum scraps into high-grade powders, in line with world-wide sustainability standards. Combined, these circumstances place aluminum powder at the forefront of the developing world of advanced manufacturing and clean technology.

Case Study on Cost Model of Aluminum Powder Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale aluminum powder manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed aluminum powder manufacturing plant in India. This plant is designed to produce 2,000 tons of aluminum powder annually.

Manufacturing Process: The production of aluminum powder takes some measured and controlled procedures to attain equal particle size, purity, and performance characteristics for industrial and metallurgical use. The process starts with high-purity metal aluminum in form of ingot or wire, which is the raw material. The aluminum is initially melted in a controlled environment to avoid oxidation. The molten metal is then atomized, the most widely used and effective production process. During this process, the molten aluminum is atomized into tiny droplets through the use of compressed air, inert gas (e.g., nitrogen or argon), or high-pressure water. The droplets solidify quickly into powder particles as they cool. Depending on the atomization medium, varying particle properties are attained, gas atomization provides spherical powders appropriate for additive manufacturing and aerospace applications, whereas water atomization provides irregularly shaped powders suited for pyrotechnics, paints, and metallurgy.

Following atomization, the aluminum powder is classified and sieved to sort particles according to size and eliminate oversized or undersized fractions. The powder is then milled by ball or jet mills to produce smaller particle sizes or required specific surface area. The powder is then dried, deoxidized, and sometimes coated to stabilize and inhibit undesired reactions during storage or use. In certain applications, mechanical alloying or mixing is done to produce custom aluminum powder composition for special applications. Lastly, the product is packaged in airtight containers under inert atmospheres to maintain quality. This well-controlled process guarantees uniform aluminum powder characteristics for use in applications across industries like automotive, aerospace, pyrotechnics, and additive manufacturing.

Get a Tailored Feasibility Report for Your Project Request Sample

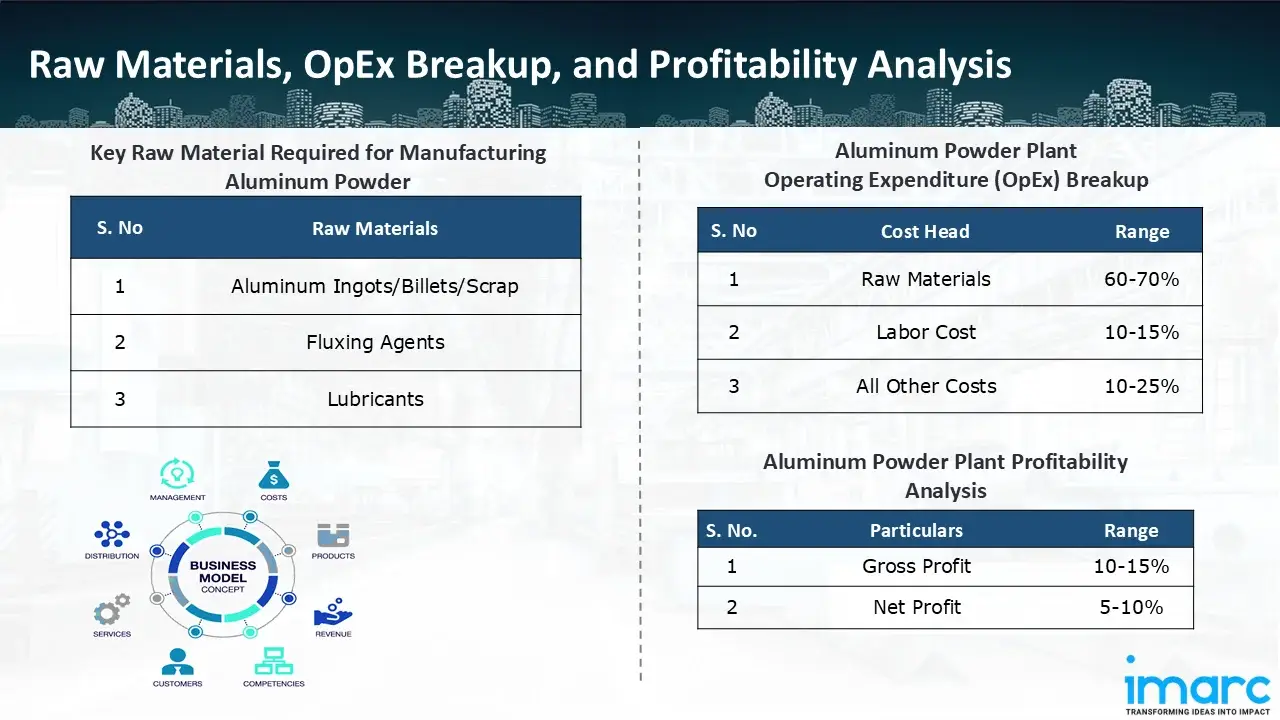

Raw Material Required:

The basic raw materials required for aluminum powder manufacturing include:

- Aluminum Ingots/Billets/Scrap

- Fluxing Agents

- Lubricants

Machineries Required:

- Ingot/Scrap Handling Crane

- Conveyors

- Bins

- Pre-Treatment Equipment (De-Coating Unit, Magnetic Separators, Scrap Cleaning Line (If Scrap Feed Is Also Used)

- Melting Furnace (Induction Furnace / Gas/Oil-Fired Tilting Crucible/ Rotary Furnace)

- Holding Furnace

- Flux Feeders

- Air Atomizer Nozzle/Atomizing Tower (Large Vertical Chamber, >15 M Tall)

- High-Pressure Air Compressors

- Dryers

- Filters (Oil-Free, Dry Compressed Air)

- Atomization Tower with Dust-Tight Collection Base

- Cyclone Separators, Baghouse / Pulsejet filters

- Vibratory Sieves / Mesh Screens

- Air Classifiers

- Ball Mill / Jet Mill / Hammer Mill

- Ribbon Blender / V-Blender

- Optional Mixers with Inert Gas Purging

- Automatic Drum/Bag Filling Machines

- Weighing Scales

- Sealing Equipment

- Dust Collectors

- Explosion-Proof Baghouses

- Spark Arrestors

- Inert Gas Systems

- Explosion Vents

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in an aluminum powder manufacturing plant ranges between 60-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 10-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 10-15%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the aluminum powder manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 2,000 tons of aluminum powder annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In December 2024, a new aluminum powder production line has been announced by United States Metal Powders, Inc. (USMP) at its Ampal Inc. subsidiary in Palmerton, Pennsylvania, USA. The new line, which is anticipated to begin full production in the summer of 2025, will have the capacity to produce both spherical and nodular aluminum powder.

- In November 2024, Continuum Powders, a manufacturer of sustainable, high-performance metal powders for advanced manufacturing, has announced the grand opening of its new global headquarters and eco-friendly manufacturing facility in Houston, Texas.

- In January 2024, KBM Advanced Materials and Sandvik have inked a distributor agreement that will allow Sandvik to sell and distribute metal powders for additive manufacturing (AM) throughout the US. The partnership will make Sandvik's Osprey® metal powders more widely available in the area.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104