Garlic Powder Manufacturing Cost Analysis: From Clove to Commerce

What is Garlic Powder?

Garlic powder is the dried form of garlic, made by drying fresh garlic cloves and then grinding them to a uniform powder. Garlic dehydration removes moisture while preserving much of the flavor, aroma, and pungency of garlic. This concentrated form offers longer shelf life, easy storage, and consistent taste compared to fresh garlic. Garlic powder is widely used as a seasoning, marinade ingredient, and flavor enhancer in culinary, industrial, and packaged-food applications. Garlic powder imparts the taste of garlic without peeling or chopping into the dishes; therefore, it is very convenient and versatile for both homes and large-scale food manufacturers.

Key Applications Across Industries:

Garlic powder has a wide variety of uses in food, food service, nutraceutical, and seasoning applications and is, therefore, one of the most sought-after dehydrated spices in the world. It is a seasoning and flavoring for soups, sauces, curries, meat rubs, salad dressings, pickles, and spice combinations because of its dispersion properties, which produce a uniform taste of garlic upon its use. Ready-to-use garlic powder reduces preparation time, enhances consistency in recipes, and alleviates many storage challenges associated with fresh garlic.

Garlic powder is a critical ingredient for snacks, instant noodle mixes, frozen foods, ready-to-cook mixes, and flavored coatings within the processed food industry. It improves the savory profile and helps maintain flavor stability during cooking and extends the product's shelf life. In snacks, garlic powder is seasoning for chips, crackers, extruded snacks, and popcorn. Nutraceutical and herbal supplement manufacturers apply garlic powder for tablet, capsule, and functional food applications, keeping in mind its antimicrobial and antioxidant properties. In addition to this, garlic powder will be incorporated into marinade powders, spice premixes, and meat processing, as it acts positively on flavor penetration and minimizes microbial growth. Its versatility further makes it a must-have for both traditional cuisines and modern packaged-food development around the world.

What the Expert Says: Market Overview & Growth Drivers

The global garlic powder market reached a value of USD 825.1 Million in 2024. According to IMARC Group, the market is projected to reach USD 844.3 Million by 2033, at a projected CAGR of 2.3% during 2025-2033. The global garlic powder market results from a combination of changing consumer lifestyles, increasing consumption of processed foods, demand for convenience ingredients, and global trade in dehydrated spices. This is one of the main driving forces: the growing demand for ready-to-use and shelf-stable ingredients. Modern consumers have busier lives, so food ingredients that save them peeling, chopping, and other preparation efforts have been in wide demand. Garlic powder comes with a consistent flavor profile, having a very long storage life, and being easy to handle.

The sudden growth of snack food, frozen food, sauces, instant mixes, and ready-to-eat foods has increased the demand for garlic powder. Garlic powder is increasingly finding its place as a seasoning in the food industry because it is inexpensive and because the pungency can be controlled according to the requirement of the consumer. Additionally, its compatibility with other seasonings increases its wide applications. QSRs and cloud kitchens will also further fuel the need for standardized seasoning ingredients, where garlic powder often plays a central role.

Other key drivers are the rising global awareness of the health benefits associated with garlic, which comprises antimicrobial, anti-inflammatory, and antioxidant properties. This has translated into increasing usage in nutritional supplements, herbal formulations, and functional foods, lending strength to the nutraceutical sector's demand. Moreover, enhanced drying and milling technologies have been improving product quality, color retention, and nutrient stability for garlic powder, making it further competitive with fresh garlic.

Global trade has also increased, as garlic-growing countries, especially India, China, and Egypt, continue to scale up production and exports of dehydrated garlic. The spice industry moving toward clean-label, natural, and chemical-free ingredients lends further support to the market, since garlic powder is well placed in formulations that are free from artificial additives. Altogether, this supports continued growth in global demand for the culinary, commercial, and health-focused applications.

Case Study on Cost Model of Garlic Powder Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale garlic powder manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed garlic powder manufacturing plant in India. This plant is designed to manufacture 300 tons of garlic powder annually.

Manufacturing Process: Garlic powder manufacturing is a highly controlled process of cleaning, drying, milling, and quality assurance that ensures natural aroma and flavor, with retention of nutritional value in a fine, shelf-stable powder. The whole process starts with choosing fresh, mature garlic bulbs, which are cleaned thoroughly to remove all traces of soil, dirt, and outer layers. The cleaned bulbs are then separated into cloves; they are peeled either manually or by a mechanical peeler and checked further to take out defective and damaged pieces. Peeled cloves are then sliced or chopped in uniform pieces, which help in maintaining uniform drying and hence prevents scorching. The prepared garlic pieces are transferred to the drying stage, one of the most critical parts of production. Manufacturers use hot air drying, tray drying, vacuum drying, or freeze-drying according to desired quality and operational setup. Most common is hot air drying, whereby garlic slices are dried at controlled temperature to reduce moisture below 6%. On the other hand, although costlier, freeze-drying preserves the maximum amount of flavor compounds and nutrients. Once completely dehydrated, dried garlic is brittle and ready for milling. The garlic flakes, after being dried, are ground into powder using industrial grinders or pulverizers until a uniform particle size is achieved. After milling, the powder is sieved to remove impurities and ensure consistent texture. Anti-caking agents may be added if the formulation requires improved flowability. Quality checks, including moisture levels, microbial contamination, color, and aroma, are conducted on the final product prior to being packaged in airtight and moisture-resistant containers to maintain freshness. This structured process ensures garlic powder retains its characteristic pungency, flavor strength, and shelf stability for culinary and industrial applications.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

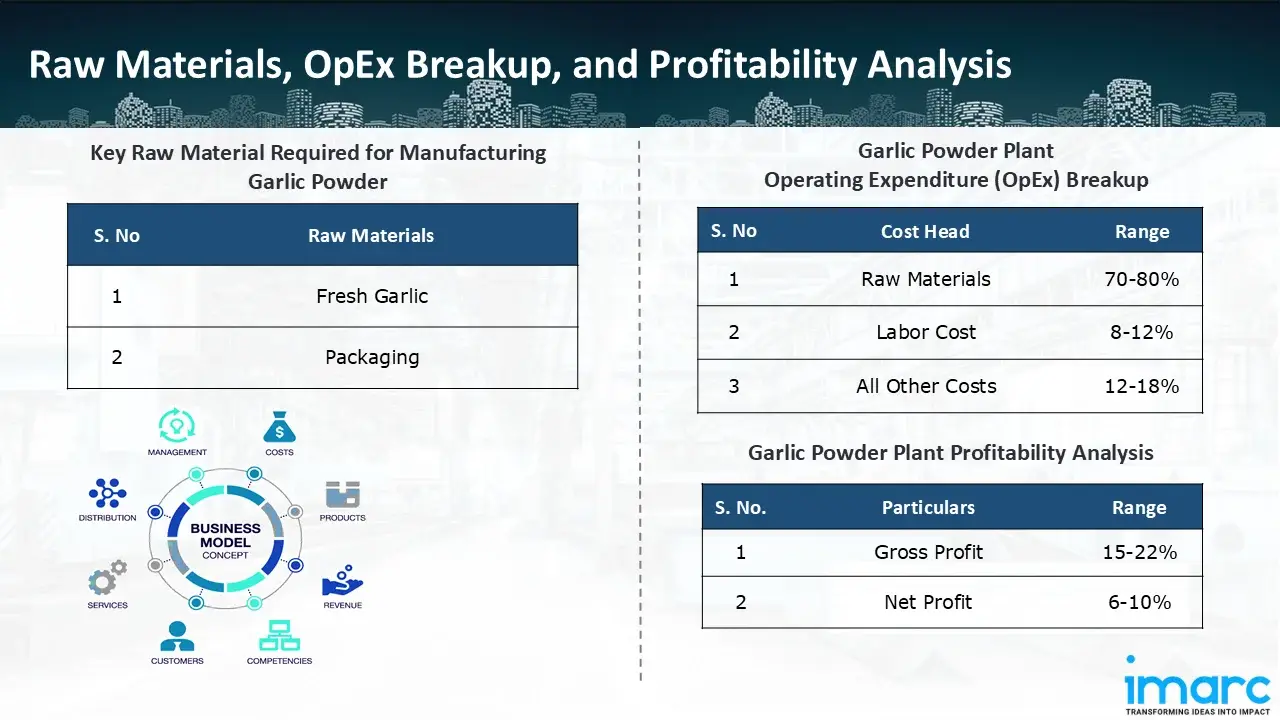

The basic raw materials required for garlic powder manufacturing include:

- Fresh Garlic

- Packaging

Machine Section or Lines Required:

- Dehydration

- Milling

- Sieving

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in garlic powder manufacturing plant ranges between 70-80%, labor cost ranges between 8% to 12%, and all other costs ranges between 12-18% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-22%, and net profit lie between the range of 6-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact

Our financial model for the garlic powder manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 300 tons of garlic powder annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In November 2025, David and Andrew Moon, fifth-generation Australian farmers, have created a novel method of producing garlic by turning unsold garlic into pure Australian garlic powder.

- In March 2025, Khonoma village in Nagaland came alive with its first-ever Garlic Festival, an event organized by the Khonoma Women Union (KWU). Backed by the Women Resource Development Department along with support from the Horticulture and Agriculture Departments, the festival aimed to celebrate garlic as the village’s key cash crop while encouraging sustainable farming practices and entrepreneurship among local communities.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104