Fruit Powder Manufacturing Cost Analysis: Value in Every Granule

What is Fruit Powder?

Fruit powder is made by removing the moisture content of whole fruits through various methods, such as spray drying, freeze-drying, drum drying, or vacuum drying, to get a finely ground, dehydrated powder form. After drying, the fruit is then milled into a stable, lightweight, and shelf-friendly powder that retains much of the fruit's natural flavor, aroma, nutrients, and color. Fruit powders have the essence of fresh fruit in concentrated, easy-to-handle form and are thus highly versatile in food, beverage, nutraceutical, and cosmetic applications. They offer an alternative to fresh fruits in a more convenient manner with longer shelf life and consistent quality for industrial use.

Key Applications Across Industries:

There has been a growing demand for fruit powders across diverse industries because of the convenience, flavor concentration, and functional benefits they offer. Within the food and beverage industry, fruit powders function as natural flavorings and color enhancers in bakery items, confectionery, smoothies, instant drinks, yogurt, ice creams, breakfast cereals, and baby foods. They enhance taste, improve nutritional value, and support clean-label formulations by replacing artificial additives. Fruit powders also have applications in the snack and ready-to-eat food industries in seasoning chips, energy bars, granola blends, and dessert mixes in powdered form.

Within the nutraceutical and dietary supplements segment, fruit powders are valued for their antioxidant content, vitamins, and phytonutrients. These are incorporated into immunity-boosting powders, effervescent tablets, herbal blends, and functional beverages. Fruit powders are used by cosmetics and personal care manufacturers in face masks, scrubs, soaps, and skincare formulations, which capitalize on their natural exfoliating, brightening, and aromatic properties. In the food service business, fruit powders make life easier with regard to storage and preparation for chefs who need consistent flavor without the perishability of fresh fruit. Their ease of transportation and long shelf lives also make them apt for exports, emergency nutrition, and specialty diet formulations.

What the Expert Says: Market Overview & Growth Drivers

The global fruit powder market reached a value of USD 20.43 Billion in 2024. According to IMARC Group, the market is projected to reach USD 28.12 Billion by 2033, at a projected CAGR of 3.6% during 2025-2033. The global fruit powder market is supported by various structural and consumer-driven factors, extending demand across industries. One of the major driving factors is the increasing desire for natural ingredients, clean labels, and no additives in foods and beverages. With greater avoidance of foods containing artificial flavors, synthetic colors, and preservatives, fruit powders represent a natural alternative that appeals to taste buds, improves nutrition, and fulfills regulatory and labeling requirements. Greater awareness related to immunity, wellness, and functional nutrition accelerates health-conscious lifestyles and has increased the use of fruit powders in supplements, fortified foods, and superfood mixes.

Another strong driver is the rapid expansion of the processed and convenience food sector. Ready-to-drink mixes, instant smoothies, meal replacements, and on-the-go foods add consistency, flavor, and extended shelf life to fruit powders. Fruit powders are increasingly being adopted in the foodservice and bakery industries, mainly to reduce waste and enhance procurement efficiency by ensuring year-round availability of seasonal fruits. In developing economies, increasing disposable incomes and a growing urbanization pace accelerate consumption of packaged foods in which fruit powders act as core ingredients.

The technological advancement in drying and encapsulation technologies, such as spray drying and freeze-drying, has enhanced product quality by preserving aroma, nutrients, and color, making fruit powders more attractive for premium applications. On top of that, the recent surge in cosmetic and personal care formulations based on botanicals and fruit-derived ingredients creates new opportunities for producers. Overall, increased global trade in dehydrated fruit products, along with lightweight, stable, and export-friendly ingredients, enhances the growth of the market. All these factors make fruit powder an essential ingredient in health foods, commercial manufacturing, and functional product development around the world.

Case Study on Cost Model of Fruit Powder Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale fruit powder manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed fruit powder manufacturing plant in India. This plant is designed to manufacture 500 tons of fruit powder annually.

Manufacturing Process: Fruit powder production is a carefully controlled manufacturing process that seeks to maintain the fruit's flavor, color, and nutrients while transforming it into a stable, user-friendly powder. The process starts with sourcing fresh fruits in their prime, followed by sorting and washing to remove dirt, pesticides, and impurities from these fruits. Cleaning is then followed by peeling, de-seeding, and cutting into smaller pieces to further facilitate uniformity in processing. Depending on the type of fruit, pulping or juicing methods are employed to achieve a smooth, consistent fruit puree. Prior to drying, puree filtering, homogenization, or mixing with natural carriers like maltodextrin could be done to achieve better texture and prevent clumping for enhanced drying efficiency. The next step is drying, which is the most critical part of the process for producing fruit powder. Common methods include spray drying, where the fruit puree is atomized into fine droplets and rapidly dried with hot air to create a free-flowing powder, and freeze drying, which involves freezing the puree and removing moisture through sublimation to retain maximum nutrients and aroma. Other techniques, including vacuum drying or drum drying, might be applied based on cost, product specifications, and quality desired. After drying, dehydrated fruit flakes are milled into fine powder with special grinders. This is followed by sieving for particle size uniformity, packaging in moisture-resistant materials, and quality control checks on purity, microbial safety, and nutrient retention. This kind of controlled manufacturing ultimately produces fruit powders that are shelf-stable, lightweight, and suitable for use in foods, beverages, supplements, and cosmetic formulations.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

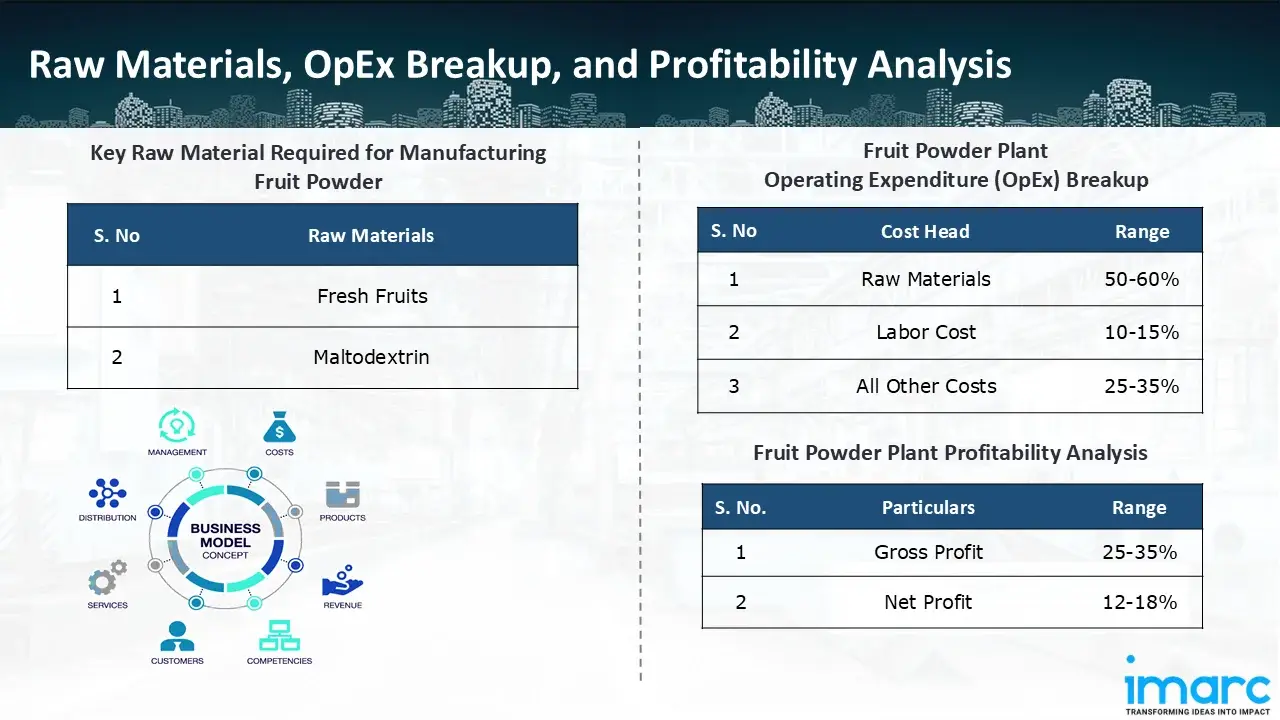

The basic raw materials required for fruit powder manufacturing include:

- Fresh Fruits

- Maltodextrin

Machine Section or Lines Required:

- Washing

- Pulping

- Spray Drying

- Blending

- Packaging

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in fruit powder manufacturing plant ranges between 50-60%, labor cost ranges between 10% to 15%, and all other costs ranges between 25-35% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 25-35%, and net profit lie between the range of 12-18% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the fruit powder manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 500 tons of fruit powder annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In March 2025, Patanjali has opened the biggest orange processing facility in Asia, with a daily capacity of 800 tonnes in Nagpur, Maharashtra. The initiative, which would cost Rs 1500 crore, focusses on zero-waste operations and creating export-quality goods to help farmers and generate many jobs.

- In May 2024, new, cutting-edge production lines for compounds and emulsions as well as powdered and liquid flavours have been added to Döhler South Africa's Paarl factory. It is also aimed at significantly improving the company's capacity to process large amounts of juice concentrate.

- In April 2024, Paradiesfrucht GmbH, a global freeze dryer of fruits, fruit preparations, yoghurts, drops, powders, and granulates, was acquired by Thrive Freeze Dry, a maker of freeze-dried products.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104