Biodegradable Plastic Granules Cost Model: Cost Dynamics and Market Outlook

What is Biodegradable Plastic Granules?

Biodegradable plastic granules are eco-friendly polymer materials designed to decompose naturally through the action of microorganisms such as bacteria, fungi, and algae, reducing the environmental burden associated with conventional plastics.

Key Applications Across Industries:

These granules are the fundamental raw materials used in the production of biodegradable products such as packaging films, agricultural mulch, carry bags, cutlery, and medical components. Derived from renewable biological sources like corn starch, sugarcane, cassava, and vegetable oils, or through chemical modification of petrochemical-based polymers, the granules are engineered to retain mechanical strength, flexibility, and processability while ensuring environmentally safe disposal. Common types of biodegradable plastics include polylactic acid (PLA), polyhydroxyalkanoates (PHA), polybutylene adipate terephthalate (PBAT), and polybutylene succinate (PBS). These materials can be fully biodegradable or blended to optimize cost and performance. The granules are manufactured through polymerization or fermentation processes, followed by pelletizing and compounding with additives to achieve specific characteristics like heat resistance, tensile strength, and degradation rate. The decomposition of these plastics results in natural by-products such as carbon dioxide, water, and biomass under industrial composting or soil conditions. As sustainability becomes a critical global agenda, biodegradable plastic granules are increasingly recognized as a vital solution to reduce plastic waste, promote circular economy models, and meet stringent environmental regulations. The global shift toward greener materials, combined with advancements in biopolymer technology, has positioned biodegradable granules as a cornerstone in the transition from linear to sustainable material systems.

What the Expert Says: Market Overview & Growth Drivers

The global biodegradable plastic market reached a value of USD 5.69 Billion in 2024. According to IMARC Group, the market is projected to reach USD 11.15 Billion by 2033, at a projected CAGR of 7.38% during 2025-2033. The global biodegradable plastic granules market is witnessing significant growth, driven by rising environmental awareness, strict government regulations, and rapid technological innovations.

One of the primary drivers is the increasing global concern over plastic pollution, which has prompted nations and corporations to adopt biodegradable alternatives. Regulatory frameworks such as the European Union’s Single-Use Plastics Directive, India’s Plastic Waste Management Rules, and similar policies in North America and East Asia are accelerating the transition toward compostable and bio-based materials. The surge in demand for sustainable packaging is another major factor, as e-commerce, food and beverage, and consumer goods industries shift toward eco-friendly packaging solutions to meet corporate sustainability goals and consumer preferences. Furthermore, advancements in biopolymer production technologies have reduced the cost gap between conventional plastics and biodegradable materials, enhancing commercial viability. Increasing investments from leading companies like NatureWorks, TotalEnergies Corbion, BASF, and Novamont are also expanding global production capacity, ensuring a stable supply chain for biodegradable plastic granules. In addition, growing awareness of circular economy practices, along with improved composting and recycling infrastructure, is strengthening the market ecosystem. The use of agricultural waste and non-food biomass as feedstocks is creating new value chains and reducing reliance on food crops. The rapid adoption of biodegradable materials in agriculture, medical, and consumer goods sectors further propels demand. As consumers, governments, and industries converge on sustainability goals, the biodegradable plastic granules market is expected to expand robustly, shaping the next generation of eco-conscious manufacturing worldwide.

Case Study on Cost Model of Biodegradable Plastic Granules Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale biodegradable plastic granules manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed biodegradable plastic granules manufacturing plant in India. This plant is designed to produce 3,500 tons of biodegradable plastic granules annually.

Manufacturing Process: The manufacturing process of biodegradable plastic granules involves several stages designed to convert renewable or partially renewable raw materials into environmentally friendly polymers suitable for diverse industrial applications. The process begins with raw material selection, where biological feedstocks such as corn starch, sugarcane, cassava, or vegetable oils are chosen as primary carbon sources. In the case of biopolymers like polylactic acid (PLA), these feedstocks are first converted into monomers such as lactic acid through fermentation using microbial cultures. The lactic acid is then purified and subjected to polymerization (either direct condensation or ring-opening polymerization) to form long-chain biodegradable polymers. For other biopolymers such as polyhydroxyalkanoates (PHA), microorganisms are cultivated in bioreactors where they synthesize polymer granules intracellularly by metabolizing organic substrates. The resulting PHA is then extracted, purified, and dried. In contrast, polybutylene adipate terephthalate (PBAT) and polybutylene succinate (PBS) are typically produced through chemical synthesis using bio-based or petroleum-derived intermediates, followed by melt polymerization. Once the base polymer is formed, it undergoes compounding, where additives, stabilizers, colorants, and plasticizers are blended to enhance performance characteristics such as tensile strength, flexibility, and biodegradation rate. The compounded material is then extruded and pelletized into uniform granules, which serve as the raw input for downstream applications like film extrusion, injection molding, and thermoforming. The final biodegradable granules are tested for molecular weight, mechanical integrity, and compostability to meet international standards such as EN 13432 and ASTM D6400. This integrated process ensures that biodegradable plastics combine high functionality with environmental sustainability, supporting global efforts toward a circular economy.

Get a Tailored Feasibility Report for Your Project Request Sample

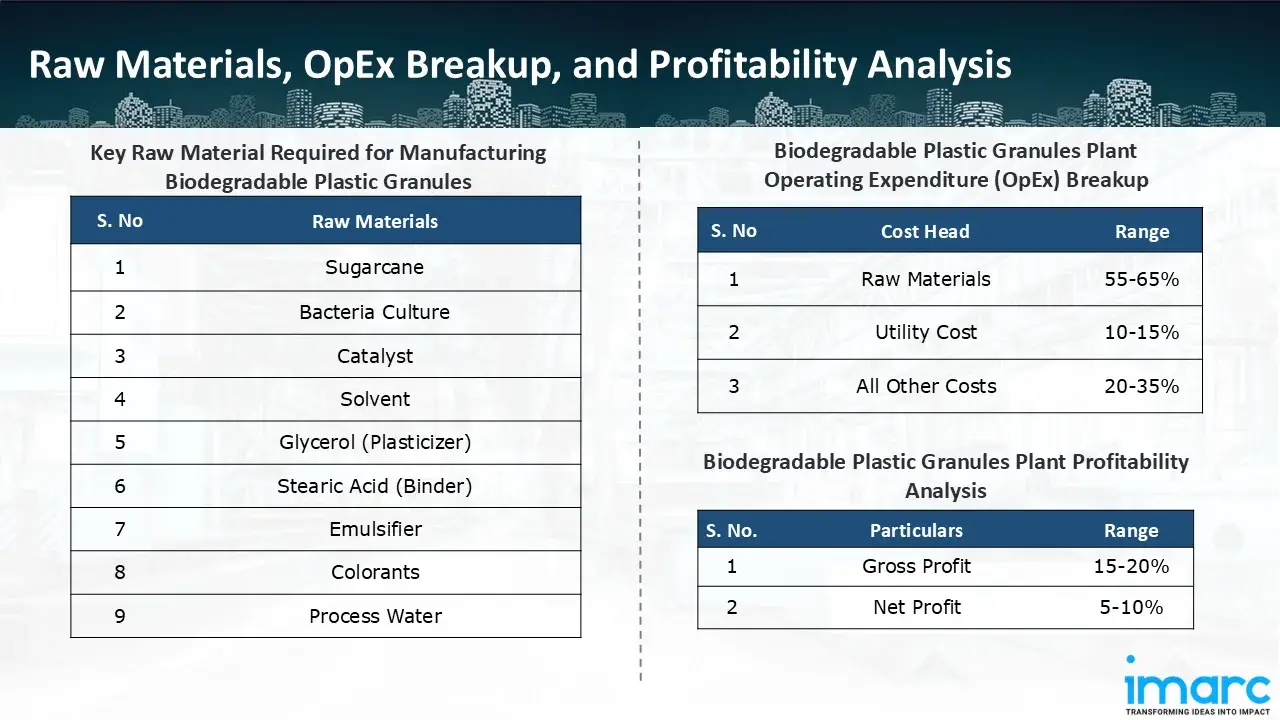

Raw Material Required:

The basic raw materials required for biodegradable plastic granules manufacturing include:

- Sugarcane

- Bacteria Culture

- Catalyst

- Solvent

- Glycerol (Plasticizer)

- Stearic Acid (Binder)

- Emulsifier

- Colorants

- Process Water

Machineries Required:

- Hoppers & Receiving Stations (for Feedstock Unloading and Metering)

- Starch Slurry Mixers / Wet Milling / Liquefaction Tanks

- Enzyme Dosing & Dosing Skids

- Enzymatic Saccharification Reactors

- Heat Exchangers / Steam Generators

- Stainless-Steel Fermenters / Bioreactors

- Seed Trains & Sterilisation Autoclaves

- Ph Control Skids

- Acid/Base Dosing Systems

- Antifoam Dosing Systems

- Centrifuges / Decanters

- Utility Systems (Steam Boilers, Chilled Water, Air Compressors)

- Centrifuges / Micro/Ultrafiltration / Membrane Units

- Ion-Exchange Units

- Electrodialysis Units

- Vacuum Evaporators / Multi-Effect Evaporators

- Distillation Columns / Rectification

- Polycondensation Reactors / Pre-Polymerisation Kettles

- Depolymerisation / Lactide Reactors

- Melt Crystallisers / Flash Distillation / Fractional Distillation Columns

- Vacuum Pumps

- Condensers

- Inert Gas Systems

- Catalyst Dosing Skids

- ROP Reactors (Tubular / Stirred Reactors)

- Vacuum Devolatilizers / Melt Filters

- Extruders (Single / Twin-Screw) With Gear Pump and Strand Die

- Melt Filters / Screen Changers

- Safety & Instrumentation

- Hot Strand Pelletizers / Underwater Pelletizers

- Crystallisation / Heat-Treatment Tunnels

- Cooling Conveyors

- Dryers

- Vibratory Sieves

- Dedusting Units

- Packaging Lines (Weighing, Bagging, Big-Bagging)

- Twin-Screw Extruder + Blown Film Line

- Steam Boilers & Deaerators; Chillers; Air Compressors; Water Treatment (ETP + MEE); Waste/Biomass Handling & Composting Systems

- Effluent Treatment Plant (ETP) + MEE, Safety Systems (Fire Water, Scrubbers, Emergency Power Genset)

- Sensors (RTD/Thermocouples, Pressure Metres, Flow Meters, Ph, Conductivity, & Dissolved Oxygen sensors, MFI (Melt Flow Index) sensors for Polymer)

- Lab Equipment (HPLC (Lactic Acid Assay), GC (Residual Monomer), DSC (Thermal Properties), GPC/SEC (Molecular Weight), FTIR, Melt Flow Indexer, Tensile Testers, Compostability Test Setup)

- Automation / DCS / PLC System

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a biodegradable plastic granules manufacturing plant ranges between 55-65%, utility cost ranges between 10% to 15%, and all other costs ranges between 20-35% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the biodegradable plastic granules manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 3,500 tons of biodegradable plastic granules annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, Geno announces the opening of the largest GENO™ Bio-BDO (1,4-butanediol) manufacturing facility in the world. The new manufacturing facility in Eddyville, Iowa, uses a single-step fermentation method to create 1,4-butanediol (BDO) from plant-based sugars cultivated in the United States using Geno's patented biocatalyst and process technology.

- In August 2025, Avantium N.V., a pioneer in circular and sustainable polymer materials, is happy to report that the sugar dehydration (SDH) unit, along with all ancillary systems and utilities, has successfully started up at its FDCA Flagship Plant in Delfzijl.

- In June 2025, significant advancements in low-carbon bioplastics are highlighted by new Luminy® PLA life cycle assessment (LCA) results released by TotalEnergies Corbion. According to the recently released whitepaper and its supporting documentation, Luminy® PLA has an 85% lower carbon footprint than traditional plastics.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104